Development of the methods of finishing non-woven fabric with brass nanoparticles

Автор: Burkitbay A., Doskalieva D.B.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 4 (138), 2022 года.

Бесплатный доступ

Studies have been conducted on the process of obtaining brass nanoparticles by means of reduction with environmentally friendly preparations in order to give biocidal properties to non-woven fabric. The aim of the study is to modify a non-woven material using silver nanoparticles to give it biocidal properties. The effective composite preparation developed for biocidal finishing of textile materials is relatively inexpensive, environmentally and toxicologically safe. Its application opens up prospects for manufacturing a wide range of competitive, environmentally friendly, bio-resistant textile materials for various purposes. Process conditions of antibacterial finishing of textile materials were the followings: an aqueous solution with brass nanoparticles was sprayed onto the surface of a non-woven fabric, then dried and heat treated at 180 °C on a thermal press. To study the biocidal activeness of heat-treated material, a microbiological investigation was carried out. Non-woven fabric processed on the basis of brass nanoparticles obtains pronounced antifungal activeness in terms of investigating C.albicansATCC 2091 and C.albicansATCC 10231 test strains. Also, experiments on toxic and skin-irritating effects of non-woven material processed by the proposed method showed its safety for human health. The developed product based on silver nanoparticles provides high indicators of bio-resistance of textile material and meets the environmental requirements for textile auxiliary substances. In the production of nonwovens, processing with this composition can be combined with the emulsification of a mixture of fibers, or carried out after the formation of the canvas with subsequent heat treatment and calendering.

Textile material, biocide substance, microorganisms, microbiological investigation

Короткий адрес: https://sciup.org/140296396

IDR: 140296396 | УДК: 677.02 | DOI: 10.48184/2304-568X-2022-4-180-187

Текст научной статьи Development of the methods of finishing non-woven fabric with brass nanoparticles

Rationale for the choosing the topic, aims and objectives

Nowadays nanotechnologies are being actively introduced into the technology for creating biocidal textile materials, making it possible to obtain materials with antibacterial properties that are safe for human health. The use of nanotechnology allows to significantly decrease costs at the main stage of production where the consumption of raw and other materials is important. One of the sharply developing areas of modern nanotechnology is the creating and using of nano-sized particles (NPs) of various metals.

The antimicrobial properties of brass NPs have long been known that are able to be used in different industries. The main advantage of brass NPs, unlike silver NPs, is their lower price and rapid degradation under environmental conditions, which reduces the burden on the ecosystem.

One of the most common methods for obtaining brass nanoparticles is the chemical method of reduction from solutions of their salts. Brass nanoparticles are obtained by reduction from solutions of their salts with reducing agents such as hydrazine hydrate and sodium borohydride, which are toxic substances, in the presence of stabilizers of various nature. In recent years, interest has increased in environmentally friendly methods for the synthesis of metal nanoparticles using non-toxic and environmentally friendly substances [1].

Based on the analysis of literature review, it was decided to investigate a method for obtaining brass nanoparticles by reduction with benzoic acid and glucose, which are environmentally friendly substances, and use guanidine hydrochloride as a stabilizer.

Non-woven materials with biocidal properties are used in construction as insulation materials. Greater practical importance has wrapping and packaging materials with antimicrobial properties. They provide longterm preservation of packed items, which can be of great use in trade, especially foreign trade. Antimicrobial cloths are also very beneficial for technical purposes, in particular, as filter materials. Filters with antimicrobial properties can be used for disinfection of fresh water as preservatives for fruit juices. Bacterial air filters are required for air conditioning and ventilation in hospitals, various microbiological laboratories. The requirement for the sterility of process air arises in the production of various pharmaceutical and cosmetic preparations, vitamins, food citric acid [2].

Materials and research Methods

Object of the study : non-woven fabric from linen and wool fibers, as well as chemical preparations (brass sulfate, benzoic acid, glucose, guanidine hydrochloride).

While researching a number of complex research methods were used. To study the surface morphology of fibers of textile materials, a JSM-6490LA field emission scanning electron microscope (Japan) was used. The breathability of the fabric was determined on the device MT-160. The microbiological investigations were carried out according to GOST 9.060–75 and GOST 9.048-89 (table 1).

Table 1 –Testing instruments and measuring devices used in the microbiological research

|

№ |

Name of the testing instrument and measuring devices |

Characteristics |

|

1 |

Thermostat incubator BD – 115 |

from +4 to +100 ºC d± 1 ºC |

|

2 |

Densitometer DEN-1 |

0-15 McF |

|

3 |

Variable volume pipette EppendorfResearch |

1-10 ml, d = 0,02 ml |

|

4 |

Variable volume pipette EppendorfResearch |

0,1-1 ml, d=1,0 mcl |

|

5 |

Variable volume pipette EppendorfResearch |

20-200 mcl; d=0,1mcl |

|

6 |

Laminar box BioIIA/G |

flow rate 1100 m3h |

|

7 |

Hygrometer VIT-1 |

from 20 % to 90 %, d = ± 0,2 ºС, ± 7% operating limit from + 15 °С to + 40 °С |

|

8 |

Nutrient agar |

рН (by 25 °С) 7,4±0,2 |

|

9 |

Sodium chloride |

hc |

|

10 |

Ethanol |

96 % |

Testing conditions : air temperature 24 °С, 60 % relative air humidity in the room.

Test strains of fungi :

-

- Candidaalbicans ATCC 10231 is test culture for testing fungicides. Test culture is taken from American Type Culture collections (ATCC).

-

- Candidaalbicans ATCC 2091 is test culture for testing fungicides. Test culture is taken from American Type Culture collections (АТСС) [2].

Main part

Results and their discussion

To obtain brass nanoparticles, an aqueous solution of brass sulfate was prepared in the presence of a stabilizer, guanidine hydrochloride. Then it was brought to a boil and a solution of benzoic acid and glucose was added. As an alkaline agent, a concentrated NaOH solution was added dropwise to pH 9-11. During the process of the reaction, the solutions changed color from colorless to deep yellow.

Process conditions of antibacterial finishing of textile materials were the followings: an aqueous solution with brass nanoparticles was sprayed onto the surface of a non-woven fabric, then dried and heat treated at 180 °C on a thermal press.

Based on a preliminary experiment to obtain metal nanoparticles, the concentration of brass sulfate varied within 3–6 g/l, guanidine hypochloride – 5–10 g/l, benzoic acid – 3–6 g/l and glucose 10 ml (table 2).

Table 2 – Structure of antimicrobial finishing of nonwoven fabric

|

№ |

Concentrations |

||

|

Guanidine hypochloride, g/l |

Brass sulfate, g/l |

Benzoic acid, g/l |

|

|

1 |

5 |

3 |

3 |

|

2 |

5 |

6 |

3 |

|

3 |

10 |

3 |

3 |

|

4 |

5 |

3 |

6 |

|

5 |

5 |

6 |

6 |

|

6 |

10 |

3 |

6 |

The biocidal properties of the nonwoven fabric were tested using a laboratory test method for resistance to microbiological degradation

(GOST 9.060–75) [3]. According to GOST 9.060–75 the material is considered resistant to bio damage at I ≥ 80%.

б

а

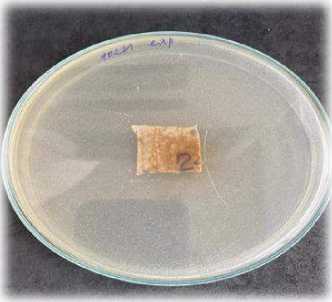

а) sample of untreated material;

б) sample of the material treated with brass nanoparticles Figure 1 – Samples of non-woven materials after bio damage

The original non-woven material after biodegradation was strongly exposed to the effects of microorganisms. There is a decrease in the density of the material sample, as well as a decrease in its strength characteristics (figure - 1).

The resistance of the treated fabric to microbiological destruction, compared to the untreated fabric, increases by 1.5 times, as evidenced by the growth of this indicator up to 96% (GOST 9.060–75). The treatment with the proposed composition of the antimicrobial finish was carried out at a concentration of guanidine hydrochloride 5 g/l, benzoic acid 3 g/l, copper sulfate 6 g/l. This indicator of the untreated material sample was 65%.

Moreover, to investigate the biocidal activeness of the treated materials, a microbiological study was carried out according to GOST 9.048-89 [4].

As a result of the study, it was found that the test sample has fungicidal activeness against the test strains under the investigation.

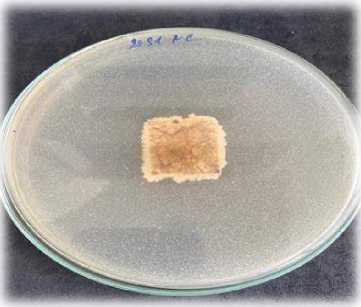

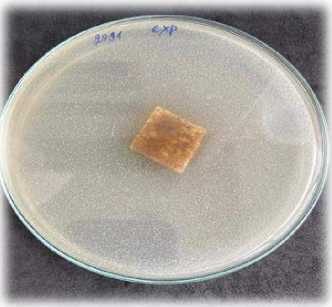

Samples of biocidal and original nonwoven materials were treated with a suspension of fungi ( C. albicans ATCC 10231, C. albi-cans ATCC 2091) and placed in Petri dishes, which were placed in a desiccator with water to create the required air humidity. Incubation was carried out at a temperature of 30°C for 28 days.

The results demonstrated that growth of the fungus C.albicansATCC 10231 was observed on the untreated controlled sample material after 5 days. The intensity of germination of the fungus was 5 points (the development of fungi covering more than 25% of the test surface is clearly visible with the naked eye). In another sample, the growth of the fungus C.albicansATCC 2091 was not noticed. After 28 days, growth of the tested fungi was observed in all control samples (Figure 2). At the same time, the growth of fungi C.albicansATCC 2091 was pointed by 4 points (the development of fungi is clearly visible with the naked eye, the fouling of the edge of the sample by microorganisms), and С.albicansATCC 10231 in control samples was rated at 5 points (the

development of fungi is clearly visible to the naked eye, the destruction of the surface of the sample material), and no growth of the tested fungi was observed on the surface of the material treated

with

brass

nanoparticles

[5–8].

C. albicans ATCC 10231 (control sample)

C. albicans ATCC 10231 (test sample)

test strain C. albicans ATCC 2091 (control sample)

Figure 2 – Growth of test strains: C.albicans ATCC 10231 and C.albicans ATCC 2091 on samples of the non-woven material

test strain C. albicans ATCC 2091 (test sample)

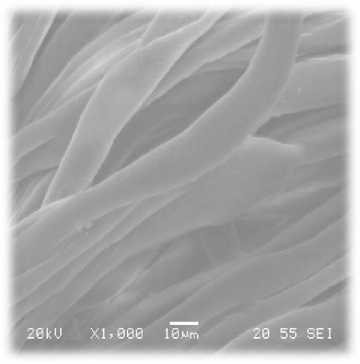

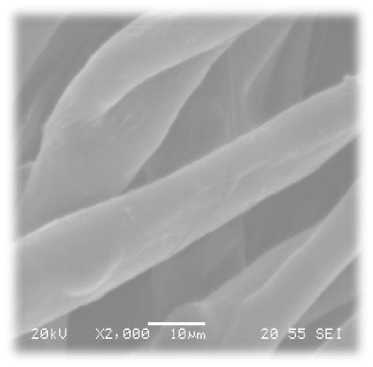

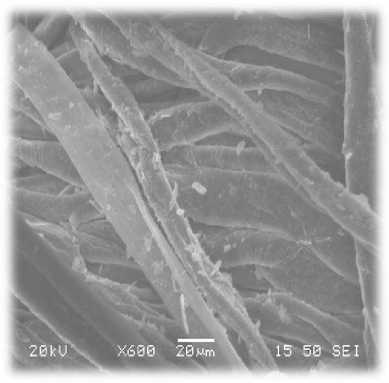

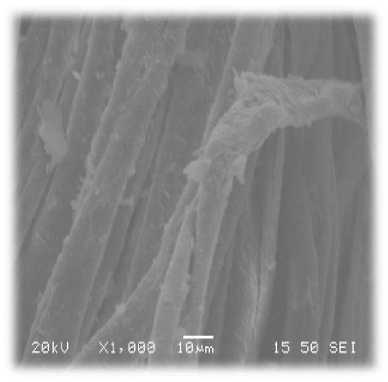

To study the surface morphology of fibers of textile materials, a JSM-6490LA field emission scanning electron microscope (Japan) was used.

а

b

c a, b) untreated samples

Figure 3 - Electron microscopic images of textile material

d c, d) treated samples

The results of scanning electron microscopy show a change in the morphological surface of the treated samples compared to untreated samples. According to the study data, it can be seen (Figure 3) that the wrap obtained on the surface of the fibers of the treated material contains brass nanoparticles. It is shown that the surface of the treated fiber has a smooth morphology and contains brass nanoparticles evenly distributed over the entire surface. It follows that the proposed composition for processing non-woven material ensures the fixing of metal particles on the surface of the fibers giving the materials high bactericidal properties.

The breathability indices of the studied samples of non-woven material were also determined. As is known, the formation of a polymer wraps on the surface of a material fiber can lead to a change in the breathability properties of the fabric.

The air permeability coefficients of the samples treated with the composition are 422.4 -548.2 dm3/m2×sec., of the untreated sample of the material - 589.6 dm3/m2×sec. This indicator of the treated material samples decreased slightly compared to the air permeability coefficient of the untreated non-woven material (table 3).

Table 3 – Indices of air permeability (breathability) of non-woven material

|

№ |

Concentration |

Indicator of air permeability, dm /(m *sec.) |

||

|

Guanidine hy-pochloride, g/l |

Brass sulfate, g/l |

Benzoic acid, g/l |

||

|

1 |

5 |

3 |

3 |

548,2 |

|

2 |

5 |

6 |

3 |

533,9 |

|

3 |

10 |

3 |

3 |

422,4 |

|

4 |

5 |

3 |

6 |

450,7 |

|

5 |

5 |

6 |

6 |

435,8 |

|

6 |

10 |

3 |

6 |

425,7 |

|

Untreated nonwoven material |

- |

- |

- |

589,6 |

Additionally, the experiments for toxic and skin-irritating effects of non-woven material processed by the proposed method showed its safety for human health. The tests were carried out in accordance with the requirements of the Technical Regulations of the Customs Union 017/2011 "On the safety of light industry products" [2].

Conclusion

Non-woven fabric processed on the basis of brass nanoparticles obtains a pronounced antifungal activeness in terms of the investigating C.albicans ATCC 2091 and C.albicans ATCC 10231 test strains.

Electron microscopic images confirm the formation of a thin polymer wrap with brass nanoparticles on the surface of the material.

The experiments for toxic and skinirritating effects of non-woven material processed by the proposed method showed its safety for human health.

Список литературы Development of the methods of finishing non-woven fabric with brass nanoparticles

- Носовская Е.А., Кудрявцева Е.В., Буринская А.А. Экологичные способы получения наночастиц меди в растворах//German International Journal of Modern Science. - №10, - 2021. - С. 47 - 51.

- Ертас А.М., Буркитбай А., Ниязбеков Б.Ж., Таусарова Б.Р. Придание биоцидных свойств утеплительным материалам из льняных волокон//Вестник АТУ, - 2021. - №2 (132), - С. 32-37.

- ГОСТ 9.060 - 75. "Метод лабораторных испытаний на устойчивость к микробиологическому разрушению". - М.: Госстандарт Россия: Изд-во стандартов, - 1976. - 21 с.

- ГОСТ 9.048-89. Методы лабораторных испытаний на стойкость к воздействию плесневых грибов. - М.: Госстандарт Россия: Изд-во стандартов, - 1995. - 15 с.

- Burkitbay A., Rakhimova S.M., Taussarova B.R, Kutzhanova A.Zh.,Application of dressing composition for antimicrobial finishing of cellulosic tekstile materials Mater. XXIII International congress " IFACC International Federation of Textile Chemists and Colourists". - Budapest: IFACC, - 2013. - Р. 123.

- Пат. 26922 РК. Состав для антимикробной отделки целлюлозного текстильного материала" / Б.Р. Таусарова, А.Ж.Кутжанова, А. Буркитбай, Е.Такей, К. Жакупова; опубл. - 15.05.13, Бюл. №5. - 4 с.

- Burkitbay A., Rakhimova S.M. Taussarova B.R., Kutzhanova Azh. "Development of polymeric composition for antimicrobial finish of cotton fabrics" //Fibres& textiles in Eastern Europe. - 2014. - Vol. 22, No. 2(104). - Р. 96 - 101.

- Burkitbay A., Taussarova B.R., Kutzhanova Azh., Rakhimova S.M.Using of watersoluble polymers antimicrobial finishing of cotton fabrics// Mater. International textile conference. - Dresden, - 2013. - С.155 - 156.