Energy efficiency analysis of the blanching process of aquatic biological raw materials in the Northern Basin

Автор: Golubeva O.A., Zhikhoruk A.A., Malaeva A.V.

Журнал: Вестник Мурманского государственного технического университета @vestnik-mstu

Рубрика: Процессы и аппараты пищевых производств

Статья в выпуске: 4-2 т.28, 2025 года.

Бесплатный доступ

The paper considers the process of calculating heat fluxes from the outer surface of the experimental plant for the implementation of combined blanching (first with water, then with steam). The aim of the study is to determine the amount of heat loss from the surface of the experimental installation with various methods of blanching seafood from the Northern Basin using the example of the stellate ramp. The experimental plant developed at the Murmansk State Technical University has a rectangular steel body, divided inside by a wall that partially separates the zones for blanching with water and steam. The studies were carried out using a Testo 875-1i thermal imager. As a result, the thermograms of the plant have been obtained for three methods of preliminary heat treatment (blanching): water treatment; treatment first with water and then with steam; steam treatment only. The working temperature range for water is 80 to 90 °C. The calculation of the heat flux from the edges of the plant’s body has been carried out considering the phenomenon of radiation heat transfer, as well as natural convection from the heated surfaces of the plant, with regard to their site in space and ambient temperature. In the course of study, bar charts with the percentage of temperature distribution over the surfaces of the plant, points with maximum and minimum temperatures have been obtained. When processing the experimental data, the coefficient of convective and radiative heat transfer, heat flux density and heat flux have been calculated for each surface. Based on the results obtained and knowing the electrical power consumption of the heating element and the steam generator, it is possible to select the type and determine the thickness of the thermal insulation layer of the plant which is to reduce heat losses and increase the energy efficiency.

Thorny skate, combined blanching, thermogram, thermal imager, energy efficiency

Короткий адрес: https://sciup.org/142246588

IDR: 142246588 | УДК: 664.9.022+66.021.4 | DOI: 10.21443/1560-9278-2025-28-4/2-711-717

Текст научной статьи Energy efficiency analysis of the blanching process of aquatic biological raw materials in the Northern Basin

DOI:

e-mail: , ORCID:

e-mail: , ORCID:

Голубева О. А. и др. Анализ энергоэффективности процесса бланширования водного биологического сырья Северного бассейна. Вестник МГТУ. 2025. Т. 28, № 4/2. С. 711–717. DOI:

The process of preliminary heat treatment or blanching is often used to improve the quality characteristics of raw materials. Blanching improves the organoleptic properties of the product, removes harmful enzymes, making it possible to turn non-food raw materials into food ones ( Shchetinskii et al., 2014 ).

Blanching as a method of preliminary heat treatment is widely used for raw materials of plant origin, mainly vegetables. There are well-known methods of blanching, for example, with steam or water, and various non-standard methods, such as microwave blanching ( Chandrasekaran et al., 2013; Lemmens et al., 2009 ), ohmic blanching ( Farahnaky et al., 2012; Mizrahi, 1996 ), infrared blanching ( Rastogi, 2012; Zhu et al., 2010 ). Blanching of stingray with steam or water, or infrared blanching is discussed in the works of Shokina Yu. V., Saenkova I. V., Raybulov S. P. ( Shchetinskii et al. , 2014; Raybulov et al., 2015 ). The use of combined blanching process for the preliminary heat treatment of the stellate stingray has so far been poorly studied ( Golubeva et al., 2018 ), developing and designing a plant for combined blanching is at the initial stages ( Zhikhoruk et al., 2020 ).

The aim of the study is to determine the quantity of heat losses from the surface of the experimental plant for various methods of blanching the fish raw materials from the Northern Basin using thorny skate as an example. To achieve this aim, the following tasks have been solved: 1) building bar charts and determining the temperatures of the external surfaces of the plant; 2) developing a three-dimensional model of the experimental plant with the imposition of the thermograms obtained; 3) determining the highest surface temperature required for the calculation and selection of thermal insulation.

Materials and methods

Investigations were carried out for various methods of blanching on an experimental plant, its design was developed at the Murmansk State Technical University (now Murmansk Arctic University – MAU). In the plant’s operation, part of the thermal energy supplied is lost into the environment, which reduces its efficiency, as a result, it requires a more powerful heating element and a steam generator Convection Heat Transfer, Fourth Edition ( Bejan, 2013 ). When operating the unit, it is necessary to consider the requirements of the regulatory documents, according to which the unit’s outer surface temperature should not exceed 45 °C (Technical Regulations of the Customs Union TR CU 021/2011, 20191).

Heat fluxes were calculated for an experimental plant of periodic action, which has a rectangular steel body, divided inside into two zones by a wall, partially dividing the zone for blanching with steam and water ( Astramovich et al., 2016 ). The installation is made of stainless steel, approved for use in the food industry, the design is protected by a patent and described in detail in ( Astramovich et al., 2016 ). A steam generator with power of 2000 W and constant productivity of 37 g/min was used as a source of steam, a heating element for heating the water with power of 2120 W was also utilized. The general view of the experimental plant is shown in Fig. 1.

Fig. 1. General view of the experimental plant (without a top cover) ( Astramovich et al., 2016 ) Рис. 1. Общий вид экспериментальной установки (без крышки)

The investigation was carried out for the developed modes of various methods of thorny skate blanching ( Golubeva et al., 2018 ).

With the Testo 875-1i thermal imager, thermograms were obtained for each individual side of the installation in the water temperature range from 80 to 90 °C in 5 °C strides for each possible method of blanching implemented on the plant (blanching with water only, blanching with steam only, combined blanching – first with water, then with steam). The water temperature was controlled using a built-in thermostat. The steam temperature was 100 °C. A detailed description of the technique for measuring the parameters of the technological process is presented in (Golubeva et al., 2018).

To calculate the heat flux, we used the equation ( Kreith et al., 2011 )

Q = a ■ A ■ A t , (1)

Вт where Q - the heat flux, W; a - the total heat transfer coefficient from the surface of the plant to the air, —— ;

м 2 ·К

A - the surface area, m 2 ; A t - the difference between surface and air temperature, K ( Kreith et al., 2011 ).

The heat flux density was determined by the equation ( Kreith et al., 2011 )

q = a ■ At,(2)

W where q – the heat flux density, .

m 2

At = ts - ta, where At - the difference between surface and air temperature, K; ts - the surface temperature, °C; ta - the air temperature in the room, °C.

Heat loss from the surface occurs through radiation and convective heat transfer ( Kreith et al., 2011 )

a = ac + a r,(4)

WW where a, - the convective heat transfer coefficient, —-— ; a, - the radiation heat transfer coefficient, —-— c , m 2 ·К r , m 2 ·К

.

The radiation heat transfer coefficient depends on the surface temperature ( t s ), air temperature ( t a ), and the degree of emissivity of the surface (ε) ( Kreith et al., 2011 )

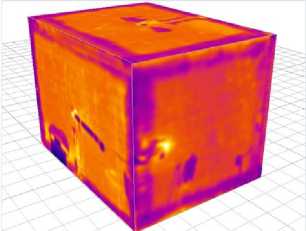

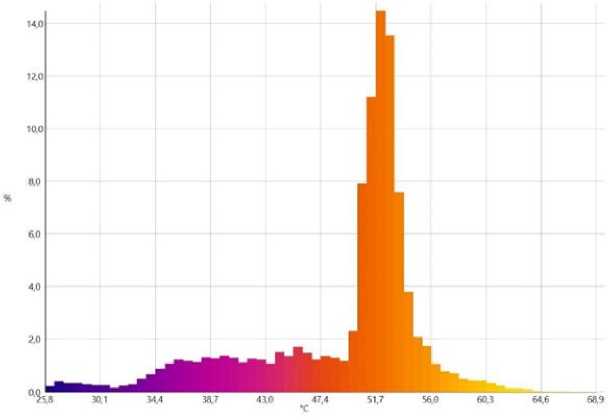

a = s5,6 7O367io- f r I (ts - ta) where ε – the degree of the surface emissivity. The convective heat transfer coefficient was calculated by the formula (Favre-Marinet et al., 2009) Nu -k a к = l0 W where Nu - the Nusselt number; k - the coefficient of air thermal conductivity, ----; 10 - the decisive surface m ■ К size, m. The equation for the Nusselt number depends on the location of the surface in space. The equations for calculating the Nusselt criterion and the restrictions imposed on them are presented in Table 1 (Bengtson, 2010). For the study conducted: I – natural convection at a vertical wall, II – natural convection over a horizontal surface, III – natural convection under a horizontal surface. Table 1. Calculation of the Nusselt criterion depending on the position of the surface of the unit in room space (Bengtson, 2010) Таблица 1. Расчет критерия Нуссельта в зависимости от положения поверхности аппарата в пространстве (Bengtson, 2010) Surface location Constraints Equations for the Nusselt number, Nu I Ra ≤ 109 0,67·Ra1/4 Nu = 0,68 +------------- Cf 0,492 Y/16 " Pr J J 109< Ra ≤ 1012 Nu = 0,387·Ra1/6 0,825+ „.,ч8/27 0,492" "I A PrJ 1 < V 7 J J 2 II Ra ≤ 109 Nu = 0,54- Ra1/4 109< Ra ≤ 1012 Nu = 0,15- Ra1/3 III 105 ≤ Ra ≤ 1011 Nu = 0,27-Ra1/4 Note: Nu is the Nusselt number; Ra – the Rayleigh number; Pr – the Prandtl number. The decisive size l0 for case I is calculated as l0 = L (Bengtson, 2010), where l0 is the determining size, m; L – the surface height, m. For cases II and III, respectively , = (BL) l 0 2{ B + L), where B is the surface width, m. Results For better visualization of the convective and radiation heat transfer process using the software, a threedimensional model of the experimental plant has been developed, thermograms being imposed on it. These three-dimensional models allow determining the highest temperature of surfaces and areas of the plant, thus detecting an increased risk of thermal destruction. Fig. 2 shows an example of a 3D model for combined blanching with 90 °C water and steam. Fig. 2. Three-dimensional model of the plant with superimposed thermogram with combined blanching with water at a temperature of 90 °C and steam (compiled by the authors) Рис. 2. Трехмерная модель установки с наложенными теплограммами при комбинированном бланшировании водой с температурой 90 °C и паром (составлено авторами) Using testo irsoft 4.5 software, bar charts with the percentage temperature distribution over the surface area have been obtained. An example of the bar chart obtained over the horizontal surface using the combined blanching method (first water at 90 °C, then steam) is shown in Fig. 3. The bar chart summarizes the percentage distribution of temperature over the test surface. On the basis of the bar charts, the average (tav), maximum (tmax) and minimum (tmin) temperatures have been determined for each face of the plant in all investigated modes. For the bar chart shown in Fig. 3, tav is equal to 49.1 °С, tmax – 68.9 °С, tmin – 25.8 °С. Using the values obtained for surface temperatures, it is possible to calculate the value of heat flux initially from each face, and then from the plant as a whole. Fig. 3. Temperature distribution over the surface area above the horizontal wall in combined blanching (first water with the temperature of 90 °C, then steam), in percent (compiled by the authors) Рис. 3. Распределение температуры по площади поверхности над горизонтальной стенкой при комбинированном бланшировании (сначала вода с температурой 90 °C, затем пар), в процентах (составлено авторами) As a result of mathematical processing of experimental data, the values of the parameters of the heat transfer process, presented in Table 2, have been obtained. Table 2. The calculated parameters of the heat transfer process (compiled by the authors) Таблица 2. Рассчитанные параметры процесса теплообмена (составлено авторами) Calculated parameter Blanching method with water, t, °C combined (first with water, t of ... °C, then steam at 100 °C) with steam, t, °C 80 85 90 80 85 90 100 Average coefficient of convective heat transfer, αc av, W m2·К 3.458 3.530 3.625 3.824 3.897 3.888 3.535 Average coefficient of radiative heat transfer, αr av, W m·К 5.448 5.493 5.555 5.689 5.748 5.742 5.483 Average heat flux density, qav, W m2 147.7 163.8 186.9 239.8 263.8 261.4 163.0 Heat flux, Qav, W 174.3 193.3 220.1 282.7 310.9 308.5 191.4 The thermal insulation of the plant should be calculated with regard to the maximum surface temperature, which is tmax= 82.7 °C. Discussion It follows from the histograms obtained that each face of the installation is experiencing significant thermal stress, causing increased wear of the material. The location of the points of peak thermal loads corresponds to the locations of the heating element installation, in the water blanching section, and the steam collector, in the steam blanching section, as evidenced by the three-dimensional model of the installation with superimposed thermal diagrams in Fig. 3. The average coefficient of convective heat transfer and the average coefficient of radiative heat transfer in the studied temperature range (from 80 to 100 °C) for the three blanching methods retain an almost constant value, which can be explained by the rather narrow recommended temperature range of the PTT (blanching) process. The average heat flux density and, consequently, the heat flux increase with increasing the temperature of the blanching medium. The minimum value corresponds to steam blanching at a temperature of 100 °C, the maximum value corresponds to combined blanching (first with water at a temperature of 90 °C, then with steam at a temperature of 100 °C). As follows from previous studies, steam blanching of stingray leads to significant protein loss, and is not recommended for use (Shchetinskii et al., 2014). Conclusion Based on the analysis of the results obtained, it has been found that the maximum heat losses are observed for the combined method of blanching (first treatment with water, then with steam) at a water temperature from 85 to 90 °C and range from 308.5 to 310.9 W. The experimental data obtained and the results of the calculation of heat losses can be used to determine the required thickness of the thermal insulation layer, which will ensure safe working conditions for personnel, reduce energy consumption of the equipment to achieve the required modes of combined blanching and, as a result, reduce financial costs of the plant’s development and operation. Conflict of interest The authors declare no conflict of interest.