Estimation of ergonomic indicators of special purpose clothing for patients with thermal injuries

Автор: Shaizadanova G.S., Kucharbaeva K. Zh., Mokeeva N.S., Loginova L.B., Abilkalamova K.K.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 4 (134), 2021 года.

Бесплатный доступ

This article discusses the determination of the optimal design allowances for a full factorial experiment in the development of special-purpose clothing for patients with thermal injuries in a hospital. To assess the ergonomic performance of special-purpose clothing, was used of pressure exerted by clothing on the human body. Based on the results of the study, a mathematical model was developed based on a full factorial experiment. In accordance with the presented mathematical models, the minimum values of contact pressures are obtained for the following values of construction parameters: for a cut with a sewn-in sleeve Warmhole = 15 cm, Ifa = 5,0 cm, Ic = 9 cm, Hse = 10 cm; for a cut with a raglan sleeve Warmhole = 15 cm, Ifa = 6 cm, Ic = 10 cm; for a cut with a one-piece sleeve Warmhole = 16 cm, Ifa = 6 cm, Ic = 11 cm.

Clothing for special purposes, values of increments, cut, mathematical model, optimization, patients with thermal injuries, ergonomic indicators

Короткий адрес: https://sciup.org/140290423

IDR: 140290423 | УДК: 687.157 | DOI: 10.48184/2304-568X-2021-4-80-85

Текст научной статьи Estimation of ergonomic indicators of special purpose clothing for patients with thermal injuries

In recent years, there has been an increase for special clothing for hospital patients. These products contribute to the effective treatment of patients with various diseases, also contributes to the psychoemotional recovery of patients. The range of heat-resistant materials is constantly updated, the flexibility, air and moisture permeability, protective properties of these fabrics are being investigated, new fire safety rules are being considered. However, the number of patients with thermal lesions does not decrease and the development of special clothing for burn patients remains relevant [1-4].

Special-purpose clothing for patients with thermal injuries is subject to increased requirements, considering the specifics of the disease. An important task in the treatment and rehabilitation of patients with thermal injuries is to provide the patient with comfortable, functional clothing that is adapted to the operating conditions, reduces the risk of infection of wounds, reduces the time of medical procedures consequent to the existence of structural elements that facilitate medical manipulations [5].

Special-purpose clothing should be comfortable during medical procedures. It should be anthropometrically consistent with the size of a hospital patient. The ergonomic indicators include: compliance of the product design with the size and shape of the human body (balance, fit of the product); comfort of the product design in dynamics; compliance of the product design with the psychophysiological characteristics of the person [6]. Recommendations on the choice of color coding for special clothing also favorably affect the psychoemotional state of the patient [7].

In this research, the compliance of specialpurpose clothing was made based on the results of the systematization of the performed medical procedures and the topography of their implementation, and on the reviews of patients of medical institutions at the experimental wear stage.

The quality of the fit of special-purpose clothing is the absence of distortions and folds on the front and back, the side seam and bottom of the garment should be flat, the absence of free folds on the surface of the parts, and the vertical arrangement of the sleeves. These indicators are measured and evaluated using the available measuring devices.

There are various methods for measuring the contact pressure exerted by special clothing on the human body: pneumatic, electropneumatic, hydraulic, strain gauge, mechanical. Depending on the purpose of special clothing, various types of sensors and devices are used: a strain gauge developed by Buzov, a device with a strain gauge pressure sensor developed by the Central Research Institute of the Garment Industry (CRIGI), a sensor developed in the Russian Correspondence Institute of Textile and Light Industry (RCITLI), the Flexiforce sensor, a capacitive method [8-13].

Materials and Research Methods

The object of the research is specialpurpose clothing for patients with thermal injuries.

Research method: measurement of the values of contact pressures of clothing on the human body using a strain gauge and determination of the optimal values of increases using the software of scientific research «MatLab».

Results and their Discussion

To study the ergonomic characteristics of special-purpose clothing was chosen a strain gauge method. The strain gauge method was chosen as the quality criterion for determining the optimal values of special clothing increases based on the dynamic compliance indicator. As a single criterion in studies of the design of special clothing for hospital patients was used the value of the contact pressure of special clothing on the human body in the area of tight fit. Other ergocriteria of dynamic correspondence selected the accompanying movement of the garment sections relative to the human body. It is in accordance with the method proposed by Professor E.B. Koblyakova [14].

The value of the contact pressure of clothing on the human body X (Pa) was chosen as the optimization criterion. To determine the influence of the main design parameters of clothing of various cuts on the amount of pressure of clothing on the human body based on the opinion of experts. The following factors were selected: for hospital shoulder clothing with a fitted shirt sleeve X1 – the width of the armhole (W armhole ), the increase of sleeve’s width (I sw , cm); X2 – the height of the sleeve edge (H se , cm); X3 – the increase in the free fit to the half-circumference of the chest, increase of chest (I fhc , cm).

For the raglan and one-piece cuts: X1 – the width of the armhole (W armhole ), the increase of sleeve’s width (I sw , cm); Х2 -the increase in the freedom of the armhole (I fa ), the increase of arm width (I aw cm); X3 – the increase in the free fit to the half-circumference of the chest, increase of chest (I fhc , cm).

For the raglan and one-piece cuts, the X4 factor was not taken into account.

The experiment was made on the samples of special clothing developed within the dissertation research for patients with thermal injuries of a straight and semi-fitting silhouette with a shirt-type sleeve, a raglan sleeve, a one-piece sleeve.

To identify the most significant design parameters of clothing that affect the quality of the fit of the garment and the freedom of movement of the sick person, an expert survey was conducted among clothing developers by means of a questionnaire. The results of the survey showed that for shoulder garments, the cut of the sleeve, the constructive additions to the free fit along the chest line, the parameters of the structural unit "armhole-sleeve" are significant.

The method of conducting an experimental assessment of the anthropometric compliance of hospital clothing designs was as follows:

-

- a pressure sensor was attached to the subject's body at the appropriate informative point;

-

- a sample of the garment made according to one of the studied design variants was put on;

-

- the subject consistently, at a given pace, performed a set of characteristic movements;

-

- contact pressure values were recorded by a voltmeter;

-

- according to the minimum pressure established as a result of the experiment, the optimal combinations of the design parameters of the garment design were determined with the characteristic movements of patients.

Thus, the value of the contact pressure of clothing, which characterizes the interaction of clothing with the human body’s surface is chosen as the studied criterion of ergonomics. The pressure acts during the entire period of operation of the garment and affects the patient's well-being. It should not create obstacles to normal movement, blood circulation and physiological processes in the human body, and cause unpleasant and painful sensations. It is possible to provide comfortable operating conditions for special clothing with an optimal range of clothing pressure on the human body. Taking into account the permissible pressure parameters it is necessary to determine the optimal design parameters of the main parts of hospital clothing for its effective operation.

Thus, for the design of basic designs of special-purpose shoulder clothing the following factors are selected as factors affecting the ergonomics of the design:

-

• cut of the sleeve (one-piece sleeve, raglan sleeve and shirt-type sew-in sleeve);

-

• increase in the freedom of the armhole depth, (cm) 4, 5, 6, 7 cm;

-

• increase in the free fit to the chest halfcircumference, (cm) in the range 7, 9, 11, 13 cm;

-

• the height of the sew-in sleeve edge, (cm) in the range 8, 10, 12 cm;

-

• the armhole width, (cm) in the range 14, 15, 16 cm.

For the pattern of the trousers designs, the increase in the half-circumference of the hips was taken into account. As a result of the research, quantitative values of the contact pressure of clothing on the human body were obtained.

Minimizing the pressure of clothing on the human body is, in modeling theory, the task of finding the extremum of the goal function

-

[15]. To process the results of the experiments and determine the coefficients of the regression equations, the factors are reduced to a single scale by encoding the variables.

The proof of the correspondence (adequacy) of the obtained mathematical model to the process under study is performed by comparing the calculated F ex (experimental) and the tabular F tab (tabular) values of the Fisher criterion. If F ex < F tab , then the mathematical model corresponds to the process under study.

After obtaining the regression equation, you should check its adequacy, i.e. the ability to describe the response surface well enough. This test is performed using the Fisher criterion, which is the following relation:

F p =max (S adec , S y ) / min (S adec , S y )

Sadec-L (Yi-AYi)2/(N-d)

where d – the number of significant coefficients in the regression equation; S y2 – reproducibility variance; S adec2 – estimation of the adequacy variance.

Based on the obtained experimental data, three mathematical models were constructed for each developed style, according to a full factor experiment (FFE) to determine the optimal values of increase for the design of special clothing.

As a result of the implementation of the FFE, mathematical models were obtained that express the dependence of the value of the "contact pressure" criterion on the selected factors for different types of movement Y1, Y2, Y3.

Y1(I)=635,64 - 4,36*x2 – 4,54*x3

Y2(I)=658,58+ 4,0*x1 +8,03* x2+7,23*х3

Y3(I)=643,73+ 6,03*x2 +7,22*х3, where Yi – estimated value of the ergonomic criterion (index i corresponds to the movement number); x1, x2, х3 – value of input factor levels (the width of the armhole, the increase in the freedom of the armhole, the increase of chest)

The adequacy of the models is confirmed by calculations, an example of which is presented in Table 1, for example, the movement of a patient with thermal lesions, lifting the arms to a horizontal position.

Table 1 - Calculated data of compliance (adequacy) of Model A to the obtained mathematical model for pressure when raising arms to the horizontal (Y1)m,

|

№ |

S bj |

t |

d |

S y2 |

S adec |

F ex |

Р, % |

F tab. |

num. |

f denom. |

|

1 |

1,82 |

2,13 |

3 |

26,95 |

64,57 |

2,3 |

96 |

2,81 |

5 |

16 |

= 5

F ex

= 2,3

F num

F tab (5/16) = 2,81

F ex < F tab

Since the tabular value of Fischer's F- criterion Ftab = 2,81 ( fnum = 5, fdenom = 16; Р -0,95) is greater than the calculated Fex = 2,3, then the resulting equation is adequate to the process under study.

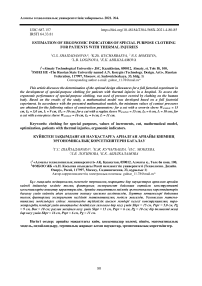

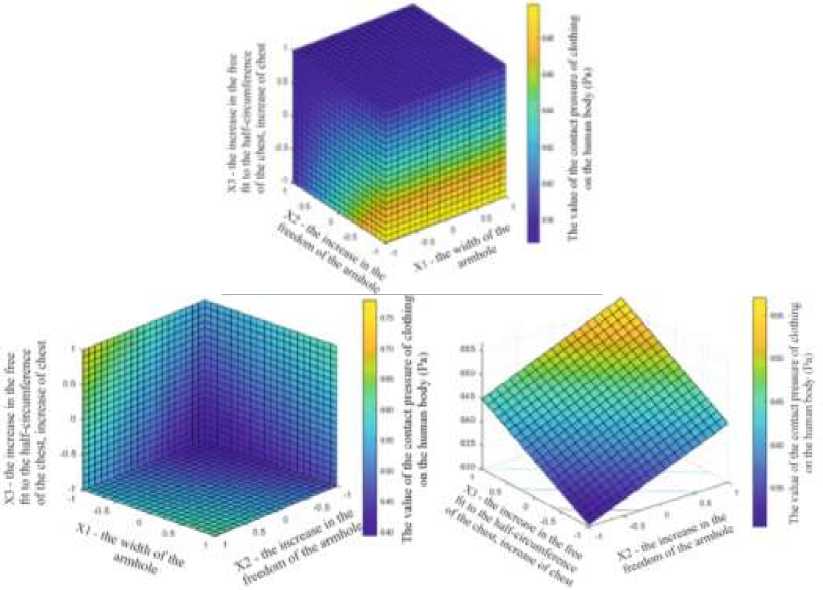

A visual representation of the pressure dependence on the structural parameters is the traces of the functions Yi (x1, x2) at x = const. Figure 1 shows the dependence of the contact pressure of clothing on the human body on the cut of the sleeve (the x variable in Fig. 1: x = -1, - corresponds to the set-in sleeve, x = 1-to the raglan sleeve) with fixed values of the increase in the freedom of the armhole 4-6 cm.

Figure 1 – The dependence of the pressure value on the construction parameters according to the values of the motion parameters Y 1,2,3 on the input factors x1, x2, x3 on the example of a shirt sleeve

Analyzing Figure 1, we can conclude that the developed mathematical models can be used to estimate the influence of each factor on the optimization parameter. The analysis of the regression equations for hospital shoulder clothing with a shirt-cut sleeve for various types of movements of the type showed that:

-

- when moving "lifting the arms forward to a horizontal level", the amount of pressure of clothing on the human body is influenced by "the height of the sleeve edge" - x2 and "the increase in the free fit to the third chest half-circumference" -x3, since these factors have large coefficients in absolute value. As the parameters increase, the amount of pressure exerted by clothing on the human body increases;

-

- when moving " the slope of the body to an angle of 90°" - the factors "increase in free fit to the third chest half-circumference " - x2, "the height of the sleeve edge" - x3, "increase in the freedom of the armhole" - x1 have the highest coefficient. When selecting the minimum values

of these parameters, the amount of pressure exerted by clothing on the human body decreases;

-

- when moving the "arm movement", the factors "the height of the sleeve edge" - x3 and "the increase in the free fit to the third chest halfcircumference" - x2 have the greatest influence. When they increase, the amount of pressure of clothing on the human body increases.

In general, a significant increase in the height of the sleeve edge, increases in the freedom of the armhole worsen the ergonomic performance of special clothing with a shirt-cut sleeve. Moreover, an increment in the increase to the third chest circumference with a significant value of the parameter does not contribute to reducing the amount of pressure of clothing on the human body.

In accordance with the presented mathematical models, the minimum values of contact pressures are obtained for the following values of construction parameters:

for a cut with a sewn-in sleeve

W armhole = 15 cm, I fa = 5,0 cm, I c = 9 cm, H se = 10 cm;

for a cut with a raglan sleeve

W armhole = 15 cm, I fa = 6 cm, I c = 10 cm; for a cut with a one-piece sleeve

W armhole = 16 cm, I fa = 6 cm, I c = 11 cm.

Thus, it should be noted that with the same values of the increase in the freedom of the armhole, the increase in the free fit to the third chest half-circumference, the width of the armhole, the height of the sleeve edge in the studied samples of products of different cuts, different values of the contact pressure of clothing on the human body occur. This can be explained by the features of the cut, structural divisions, and, consequently, the different nature of the interaction of the "person-clothing" system in dynamics, which indicates the need for a reasonable choice of cut and the corresponding values of structural increases in the design of special clothing for patients with thermal injuries, taking into account the operating conditions.

Conclusions

The developed mathematical models provide a given level of ergonomic compliance of the designed structures of special clothing for patients with thermal skin lesions, taking into account the cut of the sleeve, structural elements of clothing and operating conditions, which made it possible to develop prototypes and obtain products with a high level of dynamic compliance at the design stage, and can be used in a comprehensive assessment of the quality of the designed samples of special clothing.

Список литературы Estimation of ergonomic indicators of special purpose clothing for patients with thermal injuries

- Richard E. Lyon, Sean Crowley. Fire properties of combustible materials from unsteady burning Fire Safety Journal. - United Kingdom, March 2021. - 103054. – Volume 120. (United Kingdom). – PP 230-238

- Abu Shaid Rahman Bhuiyan, Lijing Wang. Aerogel incorporated flexible nonwoven fabric for thermal protective clothing Fire Safety Journal. - United Kingdom, October 2021. - 103444. 125. (United Kingdom). PP 650-655

- Lina Zhai, Jun Li, Yunyi Wang, Yunchu Yang. A new single-layered skin simulant and its comparison with the copper sensor for burn injury evaluation of thermal protective clothing Fire Safety Journal. - United Kingdom, July 2021. - 103370. – Volume 123. (United Kingdom). PP 440-448

- A.Richard Horrocks, Shonali Nazaré, Baljinder Kandola. The particular flammability hazards of nightwear Fire Safety Journal. – United Kingdom, June 2004. - Volume 39, Issue 4. – P. 259-276. (United Kingdom).

- Shajzadanova G.S., Kucharbaeva K.ZH., Mokeeva N.S. Research of constructive-technological solutions for the development of special appointment for burn patients The Bulletin of ATU. – Almaty, 2020. – № 2(127). – Р. 43-49. (in Kazakh).

- Classification of properties and quality indicators of clothing. – Access mode: http://modakrasot.ru/odejda--klassifikaciya/klassifikaciyasvoistv-i-pokazatelei-kachestva-odejdi.php Date of application: 02.02.2021.

- Krister Forsberg, Ann Van den Borre, Norman Henry III, James P. Zeigler. // Quick Selection Guide to Chemical Protective Clothing, 7th Edition. – March 2020 -304 p.

- Buzov B.A. Strain gauge for measuring the tensile deformation of fabric in clothing. Light industry technology. Proceedings of universities. - I960.-№5 -. Р. 95-101. (in Russian).

- The Flexiforce sensor. – Access mode: https://www.parallax.com/product/flexiforce-sensordemo-kit/ Date of application: 02.02.2021.

- Klokova N.P., Volchek A.V. Load cells. - M.: Mashinostroenie, 1999 - 220 p. (in Russian).

- Harlova O.N. Ergonomics of hospital clothes Izvestiya vuzov. Light industry technology, 2011. - №3. - Р. 64- 66. (in Russian).

- A.S. 563961 USSR, MKI A41 N1/00, A41 N43/00. A method for determining the ergonomic quality indicators of the design of shoulder garments 22.0 on a human figure and a device for implementing the method. // E.B. Koblyakova. (in Russian).

- Lai C.H.Y., Li-Tsang C.W.P. Validation of the Pliance X System in measuring interface pressure generated by pressure garment Burns. - 2009. - 35(6). - PP. 845-851.

- Koblyakova E.B. Design of clothes with CAD elements / E.B. Koblyakova, G.S. Ivleva et al. - M .: KDU, 2007. – 464 р. (in Russian).

- Kublanov M.S. Math modeling. Methodology and methods for the development of mathematical models of mechanical systems and processes: textbook. allowance. - 4th ed. - M .: MGTU GA, 2013. - Part I., –194 p.