Evelopment of sets of special clothing for cancer patiens

Автор: Abenova I.R., Zhilisbaeva R.O., Mokeeva N.S., Talgatbekova A. Zh.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 1 (135), 2022 года.

Бесплатный доступ

This article discusses the features of materials and manufactured textiles with antibacterial impregnation, contributing to the rehabilitation of patients with cancer. In addition, the results of the study of antibacterial materials for the main physical and mechanical properties are presented. Sets of clothing are proposed to improve the general state of immunity during treatment, taking into account the results of the analysis of personal data, as well as the opinions of respondents-patients and doctors. The practical significance of the study lies in the use of innovative materials with antibacterial properties intended for the development of specialized clothing for cancer patients with functional and decorative details.

Innovations, specialized clothing, antibacterial properties, cancer patients, respondents, development, rehabilitation, functional details

Короткий адрес: https://sciup.org/140293490

IDR: 140293490 | УДК: 677.17

Текст научной статьи Evelopment of sets of special clothing for cancer patiens

Most of the fabrics produced by the industry are used for the production of clothing. Clothing is necessary for a person to protect the body from the adverse effects of the external environment - low and high temperatures, excessive radiation, wind, rain, snow, etc. In addition, it protects against mechanical and chemical damage to the skin, protects the surface of the human body from dust, dirt, microorganisms, protects against insect and animal bites [1].

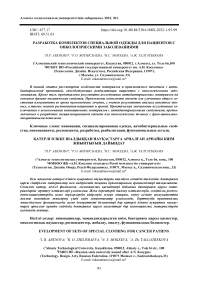

In the production of fabrics, fibrous sub- stances of vegetable (cotton, flax), animal (wool, silk) origin are used, as well as artificial (staple, silk), synthetic (nylon, lavsan). These fibers are characterized by heat resistance, hygroscopicity, air permeability, vapor permeability, water capacity, moisture evaporation, wetness, sorption properties, dust holding capacity, capillarity, and the absence of harmful impurities. These indicators relate to hygienic and are subdivided depending on the weight, thickness and porosity of the fabric (Figure 1).

Figure 1 - Hygienic properties of fabrics

In recent years, the question arises of the need to create completely new materials, the absence of which limits the possibility of producing commodities necessary for the modern national economy. This applies primarily to polymer materials, since depending on the structure of the initial monomers, conditions and methods of production, processing, they may have special predetermined properties. To impart some properties, certain substances and finishing methods are used. The processes of special treatments can be combined [2].

Due to the huge material losses caused by the action of microorganisms, currently more and more attention is being paid to the biosecurity of various materials, including textiles, damaged during their production, storage and exploitation. In addition, antibacterial and antifungal fibrous materials and products made from them are being created for the needs of medicine [3].

Object and methods of research

Innovative materials with antibacterial properties and clothing for oncopatients, taking into account the peculiarities of operation and treatment methods, are considered as objects of research.

The research method is equipment for determining the physical and mechanical properties of textiles, as well as the results of a questionnaire survey of respondents-patients and doctors.

Results and their discussion

The development of antibacterial tissue is carried out in parallel with the development of new medical technologies. Progress in this area is observed almost every year, as scientists are constantly striving to improve methods for obtaining antimicrobial coating. So, in 2007, the American scientist Stephen Michelsen developed a fabric with disinfecting properties based on highly creative dyes - profins and fluorescein. A little later, in Spain, a tissue with antimicrobial properties was created using a technique using zinc nanoparticles, ultrasound and enzymes. Now most large firms are trying to adapt a unique method of achieving antibacterial characteristics of the material based on their own developments [4].

As its name implies, this fabric is designed to prevent the spread of pathogenic microbes. In addition, there are other advantages of such a material:

-

-reducing the number of stains on clothing, as bacteria stimulate the growth of stains, and if there are none, then the fabric is less susceptible to contamination;

-

-the possibility of long-term use. Even after repeated washings, the material does not lose its properties and continues to create a barrier for microbes;

-elimination of unpleasant odors of the human body. The antibacterial properties of the tissue do not allow pathogenic microorganisms to spread on the human skin, thereby preventing the occurrence of unnecessary odors, which is very important for bedridden patients and doctors who are constantly in stressful situations (during operations) [5].

As practice shows, this fabric has only one disadvantage, but it is very significant – it is the possibility of limited use. If a fabric with antimicrobial properties is put into mass production, then in a few years humanity will receive a huge number of new microbes that will be more resistant to any protection.

Based on the main advantages and disadvantages described above, it can be concluded that at this stage the use of antibacterial tissue is acceptable only in hospital settings [6].

The growing awareness of environmental problems every year leads to the emergence of new products with unique and innovative properties, including in the textile industry. The most preferred products are those produced through the reuse of waste. Milk is one such waste, in particular, the protein casein. This protein was used in the production of textile fibers back in the 1930s, but since formaldehyde was added during its creation, production became unprofitable. In recent years, the technology of creating textile fibers has been improved. In the modern technology of creating fibers, chemical impurities are not used, which makes its production environmentally friendly. Textiles with casein fibers have high absorbent properties. Products made of such fabric have natural antibacterial properties, are comfortable to wear, especially for people with skin diseases. This opens up great opportunities for the use of textiles in the medical sector [13].

One of the urgent problems is the need to use formaldehyde in its production, in addition, a lot of water was required to create the fiber. Recent studies have found a way to produce fiber without the use of formaldehyde, but at the moment textiles obtained by this method have not been put on sale. Casein can be extracted from dairy waste, becoming the most successful alternative to other natural fibers. The smooth structure of the fibers makes the fabric as smooth as silk, and the high moisture absorption makes them softer, allowing the use of such a fabric for patients with skin cancer, making their rehabilitation period more qualitative.

Milk silk has a number of advantages, namely:

-

1. fibers are easily mixed with fibers of other materials (wool, silk, artificial and natural fur, and so on);

-

2. easy to color, evenly absorbing particles of coloring matter;

-

3. protects against UV rays;

-

4. it is sterile, has antibacterial and deodorizing effect;

-

5. its fibers are used in cosmetology, medicine, pharmacy and other sciences;

-

6. supplies the skin with vitamins A, D and E, nourishing and moisturizing it;

-

7. slows down the aging process.

Table 1 summarizes the developed innovative materials for the production of clothing with antibacterial properties. As can be seen from the table, the range of clothing produced from these materials consists mainly of underwear, sportswear, hosiery, etc.

Table 1 - Developed and commercially produced materials

|

№ |

Title |

Country of origin |

Features |

Recommendations for development |

|

1 |

Amicor Acrylic Fiber |

ACORDIS firm, Great Britain |

Prevention of bacterial reproduction. |

Underwear, shoes, sportswear, cosmetics |

|

2 |

As fabrics |

RHOVYL, France |

Contains an antibacterial substance in the fiber - this is triclosan from Ciba. It diffuses from the fiber and prevents the development of bacteria. |

Underwear, hosiery, clothes for newborns, knitting threads, bed linen |

|

3 |

Silfresh fibers |

NOVACETA, India |

Prevents the proliferation of bacteria and unpleasant odors. |

Linen products, sportswear, clothing for the city |

|

4 |

Modal Fresh fiber |

LENZING, Austria |

Prevents the growth of bacteria, gradually diffuses to the surface and causes an antibacterial effect. |

Women's underwear, socks, shirts, bed linen, sports and work clothes, terry towels |

|

5 |

Trevira Bioactive fibers |

TREVIRA CS, Germany |

Bacteriostatic action is carried out on the fiber surface, which helps to prevent skin irritation by preserving the natural bacterial flora. |

Women's underwear, sportswear, bed linen |

|

6 |

Blue Back fabrics with antibacterial effect |

TYBOR, Spain |

Smooth knitted and mesh fabrics are particularly resistant to the action of Staphylococcus aureus. |

Women's underwear, sportswear, outdoor clothing |

|

7 |

Antibacterial substance Bactekiller |

Kanebo, Japan |

When in contact with moisture, the insoluble substance becomes activated and begins to release active oxygen, thereby limiting the development of bacteria. |

Household goods, hosiery, underwear, shoes, filler materials |

|

8 |

Roica CF fibers |

ASAHI KASEI, Japan |

Absorbs bacteria and substances that cause unpleasant odors (ammonia, acetic acid, hydrogen sulfide). |

Women's and children's clothing, clothing for outdoor activities and sports, sports shoes |

Conducting an expert survey

For more efficient processing of information in this expert survey, the ranking method is selected. There are 20 men and women aged 20 to 35 years who are undergoing treatment for cancer, as well as oncologists. The answer options correspond to scores in the gradation from the most preferred to the least preferred (from 1 to 5).

The ordinal scale obtained as a result of ranking must satisfy the conditional equality of the number of ranks to the number of ranked objects. In some cases, the respondent is unable to indicate the order of two or more factors, or he assigns the same rank to different factors, and as a result, the number of ranks n is equal to the number of ranked factors [7].

For the consistency of expert assessments, the concordance coefficient W is calculated. We will consider the consistency of opinions sufficiently high if the concordance coeffi- cient is more than 0.4, average if it is 0.3-0.4 and low if 0.3. In this expert survey, the concordance coefficient was 0.6, which indicates a sufficiently high consistency of respondent's opinions.

During the analysis of the results of the expert survey, it was possible to establish the main factors of the formation of the model range:

-

- loose fit in clothes, mainly straight silhouette;

-

- the use of fabrics made of natural fibers with antibacterial treatment (cotton), since this type of fabric meets all the requirements of operation;

-

- the color scheme is preferred in light blue and greenish shades;

-

- the use of transforming parts in the production of clothing is welcome.

Thus, the competitiveness of clothing for cancer patients is determined by two factors:

shaping and the choice of materials.

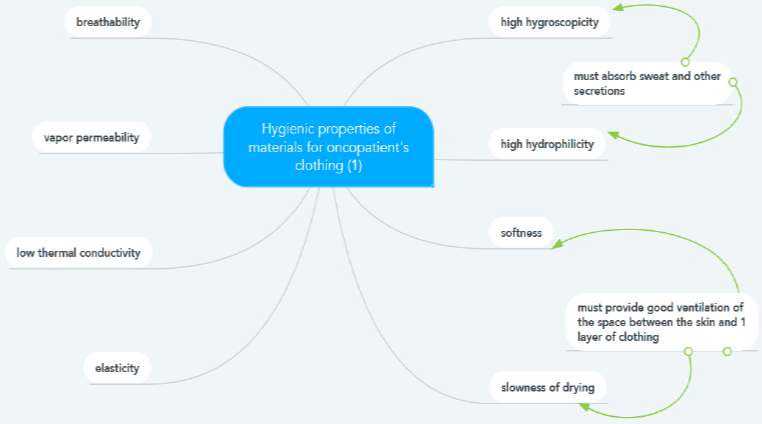

Investigation of the properties of materi-als2 experiments were conducted to determine the air permeability and the ability to pilling according to GOST (Figure 2). Bamboo fiber with silver threads and antibacterial copper fiber were selected to study the properties of the material (Figure 3).

Figure 2 - STD for designing medical clothing

Figure 3 - test materials

a) – bamboo fiber

b) – copper fiber

For the tested canvases, the number of test cycles corresponded to 125, 500 and 1000 turnovers. The tests for the bamboo canvas were carried out in 3 stages. Since bamboo fiber is made from natural fibers, at the end of 3 stages, 3 points were assigned for visual evaluation, taking into account 1000 turnovers. The tests for the cloth with copper fibers were carried out in 6 stages. The second cloth with copper fibers was awarded 5 points, taking into account 7000 turnovers. This indicator is due to the fact that where qv is the arithmetic mean of the air flow, dm3/min;

A is the test area of the point sample, cm;

167 is the conversion factor for the air flow from dm3/min*cm2, in mm/s.

The air permeability index R for antibacterial fabric with copper fibers is 0,64, for bamboo fabric with silver fibers - 5,10.

Based on the above, according to the pa- fabrics with synthetic fibers in the composition neutralize the physical impact from the outside, and are almost not pilled.

The second test was carried out in order to identify the breathability of materials. The arithmetic mean of the test results and the coef- ficient of variation are calculated with an accu- racy of 0.1% with a confidence probability of P = 0.95.

by

Air permeability R, mm/ s, is calculated the formula rameters of breathability, the fabric with silver fibers and antibacterial properties showed the best results. According to the parameter of pillingability, the best indicators are for the antibacterial cloth of black color with copper fibers [8].

Based on the results of an expert survey and processing of the data obtained, the main structural elements and the range of clothing were determined [9].

Sketches of ready-made sets of special- ized clothing for oncopatients are proposed (Figures 4, 5, 6).

Figure 4 - Tunic for female patients with oncological diseases

Figure 5 - Hoodie for patients with an internal pocket for droppers

Figure 6 - Knitted trousers for oncopatients

Conclusions

Clothing for patients with oncological diseases should take into account not only the usage conditions, but also be comfortable, functional-constructive, ergonomic and provide physiological and psychological comfort to the patient, protect against the negative effects of medications, have a rehabilitating beneficial effect on the patient's body undergoing the re- habilitation period. The solution of this task requires the formation of a rational assortment for cancer patients, as well as an increase in the efficiency of the production process of its development, which will allow designing universal clothing sets for a number of diseases.

The development of clothing made of innovative fabrics with antibacterial properties, taking into account aesthetic and functional- constructive functions, will not only facilitate medical procedures taking into account the course of the disease, but also greatly facilitate the rehabilitation of patients, increase the level of psychological and social protection of patients, which in the future will lead to an extension of life and improve its quality.

In connection with the advantages and disadvantages of the works studied in the course of the study, there is a need to improve the design process of clothing made of innovative fabrics with antibacterial properties for patients with oncological diseases.

Список литературы Evelopment of sets of special clothing for cancer patiens

- Stelmashenko, V.I. Materials for clothing and confection: textbook / V. I. Stelmashenko. - 2nd ed., supplement - M.: Academy, 2010. - 320 p. (In Russ.).

- Practicum on materials for clothing and confection: textbook / V.I. Stslmashsnko, N.A. Smirnova, T.V. Rozarsnova, Yu.V. Nazarova - M.: ID "FORUM": INFRA-M, 2019. - 144 p - (Higher education). - 978-5-16-103571-9. - Text: electronic. URL: https://new.znanium.com/catalog/product/1020702 Access date: 23.10.2021 (In Russ.).

- ISBN: 978-5-16-103571-9

- Pyzhurin, A.A. Methods and means of scientific research: textbook / A. A. Pyzhurin, Pyzhurin A.A.(ml), V. E. Pyatkov. - M.: Infra-M, 2021. - 264 p.

- Methods and means of scientific research: a textbook / E. V. Kantieva. - 1.87 mb., - PDF. - Voronezh: VGLTA, 2012. - 107 p.

- Designing of sewing products: 10th ed., ster. / E. K. Amirova; Amirova E.K., Sakulina O.V., Sakulin B.S., Trukhanova A.T. - M: IC "Academy", 2017. - 432 p.- (Professional education).

- Talgatbekova A.Zh., / Research of clothing and existing innovations for the rehabilitation of cancer patients / Abenova I.R. // Abstracts of reports of the Republican scientific and practical conference of young scientists "Science. Education. Youth", dedicated to the 175th anniversary of Abai Kunanbayev. - Almaty, 2020 PP.- - 94-96. (In Russ.).

- Marie Carolin Bier, Sophia Kohn, Antonia Stierand, Nils Grimmelsmann, Sarah Vanessa Homburg, Andrea Ehrmann, Investigation of the casein fibre production in an Eco-friendly way // Aachen Dresden Denkendorf international textile conference. Dresden, November 24-25. - 2016. - URL: https://www.researchgate.net/publication/310832654_Investigation_of_the_casein_fibre_production_in_an_eco-friendly_way Access date: 24.10.2021.

- Economics and organization of production: textbook / edited by Yu.I. Treshchevsky, Yu.V. Vertakova, L.P. Pidoimo; hand. author. col. Yu.V. Vertakov. - Moscow: Infra-M, 2020. - 381 p. - 978-5-16-006517-5 (In Russ.).

- ISBN: 978-5-16-006517-5

- Janace, E. Bubonia. Apparel Quality. A Guide to Evaluating Sewn Products / Janace E. Bubonia. - London: Bloomsbury, 2014. - 384 p.