Food safety and HACCP system in the enriched cottage cheese production

Автор: Alibekov R.S., Yunusova A.A., Bakhtybekova A.R.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 4 (113), 2016 года.

Бесплатный доступ

In this article determination and the principles of a management system of food safety of HACCP are considered. Cottage cheese production processes with a probiotics, berry syrup of a dogrose and wheat oat flour taking into account the principles of the HACCP system are analyzed. Dangerous factors, critical control points are determined. The most dangerous production stages are: milk acceptance, pasteurization, souring and packing. Authors of article offered the controlling of hazard actions.

Food safety, cottage cheese, wheat oat flour, dogrose, haccp, probiotic

Короткий адрес: https://sciup.org/140205089

IDR: 140205089 | УДК: 637.146.32

Текст научной статьи Food safety and HACCP system in the enriched cottage cheese production

Food is one of the most important components of life of people at all times. Consumers are interested in the receipting of food products, a high-quality and safely for health, and producers aim to satisfy the consumers demands in the maximum degree. Safety of foodstuff becomes more and more global and important problem [1].

Safety of food products is the concept according to which the food products won't do harm for the consumer if it is prepared and/or eaten according to the appropriate application. For the implementation of the specified concept mechanisms on production and turnover of safe food product are necessary, and one of such mechanisms is the safety management system of food. Investments into safety management systems of food - a key prerequisite of reliable and stable supply of safe food products and growth of international trade.

Safety is the basic requirement to indicators and characteristics of product quality and the requirement are established in the technical regulations (TR). № 880 was approved by the decision of the Commission of the Customs union of December 9, 2011 the Technical regulation of the Customs union of TR CU 021/2011 "About safety of food products".

According to the item 2 of Art. 10 of the Technical regulation of the Customs union "About safety of food products" in case of implementation of production processes (production) of food products, the producer (manufacturer) shall develop, implement and support the procedures based on the principles of HACCP. [2].

Now the HACCP system is the main management model and regulations of quality of food products, the main instrument of ensuring its safety where special attention is paid to so-called critical points of control in which all existing types of the risks connected with the use of foodstuff as a result of purposeful control measures can be providently prevented, removed and reduced to reasonably acceptable level [3].

HACCP — (Hazard Analysis and Critical Control Points) is a safety management system of foodstuff which provides control at all stages of a food chain, in any point of production process, and also storages and sales of products where there is a probability of emergence of a dangerous situation.

The system shall be developed taking into account seven basic principles specified in the regulating documentation. Relying on these principles, at all stages of a production process of cottage cheese it is necessary to carry out control, beginning from acceptance of raw materials and finishing with sales of products, on each processing line and on each transaction it is necessary to reveal and manage dangerous factors (microbiological, toxicological, chemical, physical, etc.) which can threaten safety of products.

The main criterion of degree of danger of this or that factor is the level of a risk probability of emergence of this factor.

The ultimate goal of system is to minimize risks or in general to reduce them until zero [3].

The purpose of work is development of the production technology of the enriched cottage cheese with vegetable additive in the form of ground wheat oat flour, berry syrup of a dogrose and probiotics with use of the principles of HACCP.

Methods of a research

The researched cottage cheese with functional nutritional supplements in the form of ground wheat oat flour, berry syrup of a dogrose and probiotics, has the enriched properties, with the high vitamin activity, nutrition and biological value improved by organoleptic indicators.

The following components are necessary for receipt of cottage cheese with functional nutritional supplements:

-

- the cow's milk prepared in accordance with GOST 31449-2013;

-

- the bacterial medicine "Bifidumbakterin" consisting of bifidobacteria of Bifidobacterium-longum or Bifidobacteriumbifidum and lactic bacteria of Lactococcuslactissubsp. diacetilactis with addition or without Streptococcussalivarius-subsp addition. thermophilus on TU 49 1016-85;

-

- wheat oat flour in accordance with GOST 9353-90.

-

- berry syrup of a dogrose in accordance with GOST 1994-93

In the provided work basic provisions of ISO 22000:2005 of System of management of safety of foodstuff were used. Requirements to any organizations in a product chain [4].

Results and discussion

In the provided work the analysis of probable dangerous factors in case of cottage cheese production was carried out.

Taking into account the principles of the HACCP system, cards of production processes, and also plans of HACCP are developed with indication of:

-

— critical control points;

-

— potentially dangerous factors;

-

— maximum permissible parameters;

-

— procedures of monitoring of the reasons which are directly influencing product quality;

-

— schemes of actions of control.

As sources of dangers all production phases were analyzed: raw materials acceptance, storage, pasteurization, separation, chilling, ferment introduction, souring, cutting of a clot, department of serum, addition of cream or butter pouring, cottage cheese chilling, packing, storage and transportation. The generalized results of work are provided in the table 1 [5].

Table 1 - Analysis of Dangerous Factors in case of cottage cheese production

|

№ the name of transaction |

Process parameters |

Considered factor |

Controlled signs |

Warning actions |

Responsible person |

|

1. Acceptance of raw milk |

Acidity <180Т |

Microbiological |

a) bacterium of group of colibacillus (BGC), b) pathogenic microorganisms, including salmonellas |

Control at reception |

Head of the laboratory |

|

Chemical |

a) inhibitors, b) toxiferous elements c) aflatoxins, d) antibiotics. |

Entrance control |

Head of the laboratory |

||

|

2. Pasteurizati on |

Т= 85÷87 0С with endurance of 5-10 min. |

Microbiolog ical |

At non-compliance with temperature condition, there is a probability of detection: a) bacterium of group of colibacillus (BGC), b) pathogenic microorganisms, including salmonellas. Elements of detergents in pasteurization cooling installation |

Control of the mode of pasteurization of milk. High-quality washing and disinfection of the equipment. |

Laboratory assistant-microbiolo gist |

|

3. Milk separation |

Physical |

Insufficient separation of milk (breakage of the equipment). |

Scheduled preventive maintenance of the equipment. |

Foreman |

|

|

Microbiolog ical |

Elements of detergents in the separation plant (low-quality washing of milk). |

High-quality washing and disinfection of the equipment. |

|||

|

4. Cooling of milk of |

5 min. up to the souring temperatu re (in warm season to 28-30°C, in cold -to 3032°C) |

Microbiological |

Growth of the present bacteria at violation of conditions of temperature Bacteria of group of colibacillus |

Control of the mode milk cooling |

Foreman |

|

5. Introduction of ferment, chloride of calcium and abomasal enzyme |

Amount of ferment 1 to 5%. |

Microbiological |

|

Strict control of the brought ferment |

Foreman |

|

6. Souring |

Duration souring of 4 - 6 h. |

Microbiolog ical |

|

Strict quality control of the water used in a cottage cheese production process; |

Laboratory assistant-microbiolo gist |

|

7. Cutting of a ready clot |

Т=6 0 С |

Microbiolog ical Physical |

Bacteria of group of colibacillus Foreign impurity Metal parts of the equipment |

Creation of aseptic conditions Use of the metaldetector |

Foreman |

|

8. Selfpressing |

At a temperatu |

Microbiolog ical |

a) Pollution of bags; - increase in acidity of curds; |

Observance was corrected on |

Foreman |

|

and pressing under pressure |

re not above 16 °C not less than 1 p also proceed. |

b) BGKP |

processing by the bags; control of temperature condition |

||

|

9. Cottage cheese packaging, storage and transportati on |

At a temperatu re not above -18 °C, and it isn't below -25 °C, in case of humidity of 75% 4 months are allowed to store curds. |

Microbiolog ical Chemical Physical |

1. a) BGKP; b) mesophilic and aerobic, facultative anaerobic m / about 2. a) Pollution by lubricant; b) insoluble calcic and magnesian soaps. 3. Metal parts of the equipment |

Creation of aseptic conditions Use of the metaldetector |

Foreman |

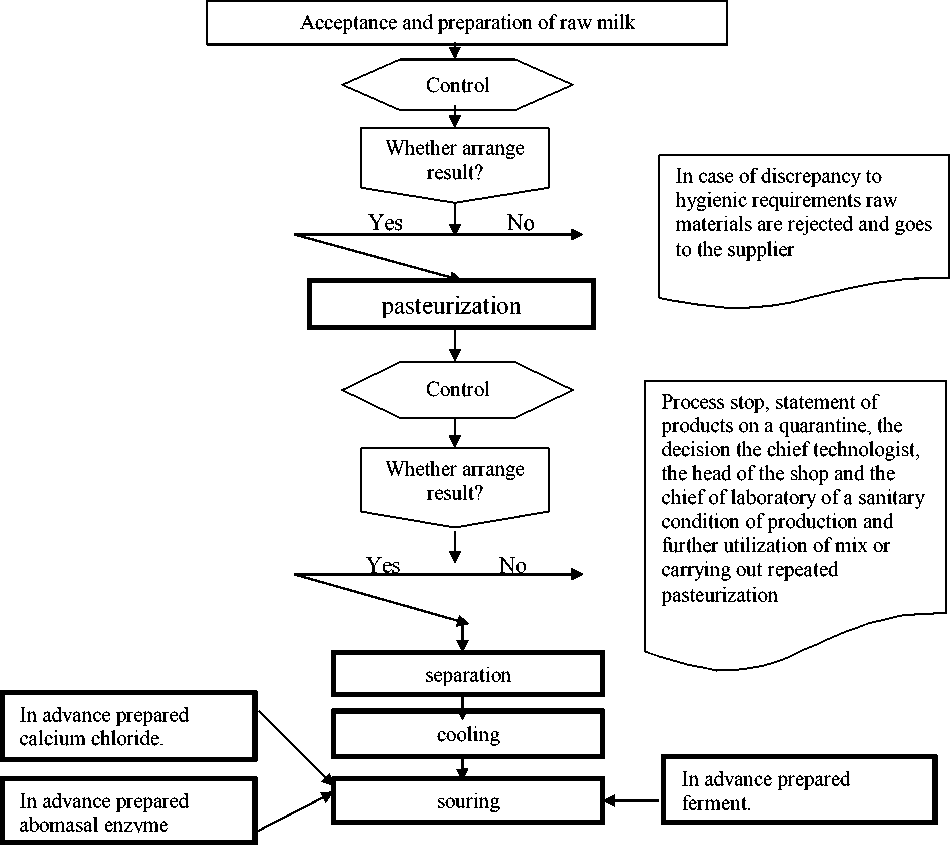

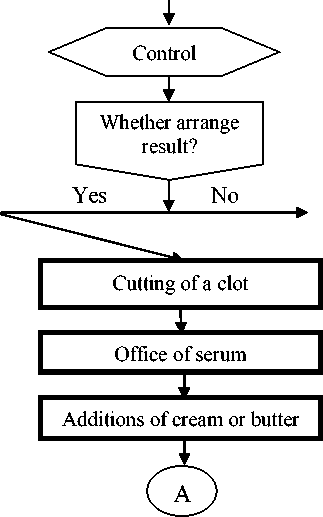

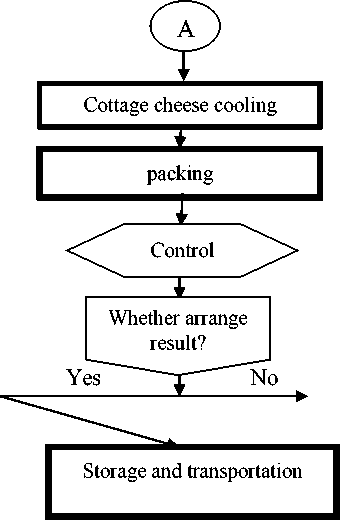

The technological scheme of receiving cottage cheese with identification possible CCP (Critical Control Points) is submitted in the figure 1.

Process stop, statement of products on a quarantine, the decision the chief technologist, the head of the shop and the chief of laboratory of a sanitary condition of production and further utilization of mix

Process stop, statement of products on a quarantine, the decision the chief technologist, the head of the shop and the head of laboratory of a sanitary condition of production and further utilization of mix

Figure 1- Technological scheme of receipt of cottage cheese

The following stage is determination of engineering procedures which it is necessary to carry to CCT which should be controlled and tracked to minimize or exclude potential dangers (table 2). It is acceptance milk, pasteurization, souring and packing. All these production stages are basic and influence quality and safety of a ready-made product.

As the main criteria for assessment of CCT changes of temperatures on time were accepted. Strict monitoring of the technological modes and corrective actions will provide decrease in degree of risks in production of fermented milk products as cottage cheese [6].

Table 2 - Risk assessment in CCT and the controlling actions in case of production of a dairy product

|

CCТ |

Risk |

Controlling actions |

Risk degree |

|

CCТ 1 |

Acceptance of raw milk |

Milk storage temperature Т= 4±20С. Absence of thr heavy metals, antibiotics, aflotoxines. |

High |

|

CCТ 2 |

Milk pasteurization |

Observance of strictly limited temperatures of pasteuri-zation Temperature, 92-95C duration, 20-30sec. |

High |

|

CCТ 3 |

Souring |

Control of the mode of souring: 4 - 6 h. Before achievement of acidity 80-1000T (рН 4,5-4,65). |

High |

|

CCТ 4 |

Packing |

Observance of all rules to avoid the admission of foreign impurity and metal particles. Observance of the mode of storage. |

High |

Conclusion

Thus, the analysis of the most probable dangers was carried out to production technologies of the enriched cottage cheese with a probiotics, berry syrup of a dog rose and wheat oat flour, with use of the principles of HACCP. Critical control points, potentially dangerous factors and risks are determined (biological, chemical, and physical). Are the most dangerous: milk acceptance, pasteurization, souring and packing. All these production stages are basic and influence quality and safety of a ready-made product. Corrective actions and system of monitoring of control on CCT are also offered.

Список литературы Food safety and HACCP system in the enriched cottage cheese production

- Dzhurupova B. K. Interrelation of food and food security -a present problem. Consumer market of Eurasia: the current state, the theory and practice in the conditions of the Eurasian Economic Union and the WTO/collection of articles III of the international scientific and practical conference, on March 30-31, 2015, Yekaterinburg, Russia. -PР.33-39.

- German L. G., Pasko O. V., Penzina O. V. Use of the principles of HASSP in case of development of technology of a cottage cheese bioproduct//the Agrarian bulletin of the Urals. -2014.-№ 8 (126).-PР.34-37.

- Kodzhegulova D. A., Dakirova M. D. About problems of safety of foodstuff//KGTU News of I. Razzakov. -2016.-Volume 36. -No. 3. -PР. 273-278

- Requirements to any organizations in a product chain of URL:http://www.iso.org/iso/ru/catalogue_detail? csnumber= 35466 (date of the address 07.12.2016).

- Alibekov R.S., Yunusova A.A. Probiotics, prebiotics and synbioticsin the foodstuffs. Materials of the international scientific and practical Internet conference "Innovative Potential of Development of Science and Technology"/the academician of MIA devoted to anniversary, d.сh.s., prof. Batkibekovа, 10-11december of 2015. Bishkek, Kyrgyzstan-РP.135-138.

- Alibekov R.S., Yunusova O.A., Gabrilyants E.A., Iskakova S.K., Orazbayev Zh.I. Modern Technologies of cottage cheese production. International conference of industrial technologies and engineering (ICITE 2016), on October 28-29, 2016 Shymkent, Kazakhstan. -РP.298-302.