Microbiological cleanliness of production areas is the way to microbiological stability of bread in storage

Автор: Zhakataeva A., Kurmanbaeva I.N., Ibraimova C.E., Uazhanova R.U.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Естественные науки

Статья в выпуске: 1 (91), 2012 года.

Бесплатный доступ

In this article studying of influence of daily disinfection processing of surfaces of placements on their to sow a moldmushrooms under production conditions is shown. It is shown as within 4 weeks disinfection processing of the fixed sites of surfaces of walls and a floor of a production room was carried out by solutions of studied disinfectants of optimum concentration. As control used processing by tap water.

Bread, mould, potato illness, microbiological damage, storage

Короткий адрес: https://sciup.org/140204938

IDR: 140204938 | УДК: 664.60

Текст научной статьи Microbiological cleanliness of production areas is the way to microbiological stability of bread in storage

In modern conditions the production of packed bakery products with long shelf life is one of the main directions of development of baking industry in Kazakhstan, which is caused by the need to enhance food safety of products, supply of ecological trouble areas, remote regions, amid man-made disasters, crisis and emergency situations.

A topical issue of production of bakery products with extended shelf life is to increase their microbiological storage stability - to prevent molding and the development of the potato disease.

In connection with the above, the actual is the determination and scientific justification of criteria of molding, as assessment of microbiological stability during storage of bakery products, to determine relationships between microbiological status of raw materials, production process and the molding process of bakery products, as well as the development of effective means to improve the microbiological stability of bakery products.

The aim of this study is to develop ways to improve the microbiological purity of the production facilities.

On the microbiological stability during storage of bread to a large extent influenced by the number of molds in the air, which, in turn, is dependent on the health of industrial premises. Sanitary condition of the premises depends on the organization of production, the frequency and patterns of washing and disinfection.

One of the ways to solve the problem of providing a high level of sanitary condition of companies is a surface treatment of industrial facilities with disinfectant. Currently, the bakery factories to disinfect used mainly chlorinated lime and soda ash. However, free chlorine has an adverse impact on human health, and in addition, the chlorination of organic substances are formed mutagenic compounds. Disinfectant properties of soda ash are negligible, so it can only be used as a cleanser. This necessitates the development of new methods of sanitizing and disinfecting the premises bakeries with a disinfectant chemical nature.

For the experiments the preparations were taken with the following characteristics:

-

- Hazard class according to GOST 12.1.047-76 - no higher than the third;

-

- Ease of preparation of working solutions;

-

- The concentration of working solutions;

-

- <5% at exposure <20 min;

-

- The possibility of using in the baking industry.

For the following studies were selected domestic and imported disinfectants “DIVOSAN-FORTE”, “BIOR-1”, “Nika-2”, “Vapusan-2000”, “Samarovka”, “Deohlor-tablets”, as active ingredients (AI) which use quaternary ammonium compounds (QAC), peroxides, halogens, acids and alkalis (Table 1).

Table 1 - Characteristics of disinfectants

|

Preparation |

The main components |

|

Bior 1 |

QAC |

|

Nika-2 |

QAC + NaOН + water softeners |

|

Vapusan-2000 |

QAC + alcohol |

|

Samarovka |

QAC + alcohol |

|

Divosan- forte |

peracetic acid + acetic acid + H2O2 |

|

Deohlor-tablets |

Dichloroisocyanuric acid |

Fungicidal properties of aqueous solutions of disinfectants were studied in relation to the test-microorganisms, pollutants typical baking deposited on the surface of the test objects. As a result of numerous studies (1, 2. 3. 4, 5. 6) found that the most frequently on the surface of the bread developed mold fungi of the genus Aspergillus and Penicillium. Therefore, as the test organisms used the molds Aspergillus niger MF 185 and 735 Penicillium roqueforti.

The main objects of disinfection are usually walls, floors, equipment and inventory. Therefore, as a test object were used the following types of surfaces: tiles, floor tiles, linoleum, metal (stainless steel), wood, painted with oil paint.

Solutions of disinfectants, which are carried out by sanitization in the baking industry enterprises are prepared using room temperature water or hot (of water). In this regard, the processing of test surfaces used disinfectant solutions with a temperature of 20-30 °C and 40-50 °C.

We determined the fungicidal effect of preparations on the basis of which selects the best mode of application of aqueous solutions in order to disinfect the surfaces of industrial premises in the baking industry enterprises of the Almaty region. Experiments were carried out according to the procedures outlined in the manual (Research Methods disinfectants to assess their efficacy and safety, 1998). Considered a sufficient processing mode in which the disinfecting activity of the preparation in all the investigated test surfaces and test organisms reached 99.99%.

Sanitization includes production facilities, as a rule, treatment of the walls and floor. In accordance with the Sanitary cleaning of floors should be done every shift wet, walls as needed. Floor treatments provide solutions of disinfectants only in the premises of enterprises producing confectionery with cream. However, studies have shown that such a regime sanitization cannot achieve the required level of microbiological purity industrial premises than is caused by the need to develop other modes of decontamination.

We studied the effects of daily disinfection of premises on the surface treatment of molds contamination in a production environment. To do this within 4 weeks of treatment was carried out disinfection of surfaces of fixed walls and floors of production premises solutions investigated the optimal concentration of disinfectants. As a control, treatment of tap water.

The obtained data indicate a reduction of contamination of the floor and walls of fungi in the processing of all the investigated disinfectants.

However, preparations containing QAC as active ingredients, not only markedly reduced the surface contamination of industrial premises bakeries, but also supported the cross on the lower level. This can be explained by the fact that QAC, interacting residues of organic substances that are on the treated surface, capable of producing microfilm is difficult to wash off that has fungicidal properties. Spores of fungi, once on a microfilm, die.

Thus, the use disinfectants based on the QAC process developed by the regime has allowed not only to reduce the contamination of surfaces production facilities, but also to maintain it at a low level.

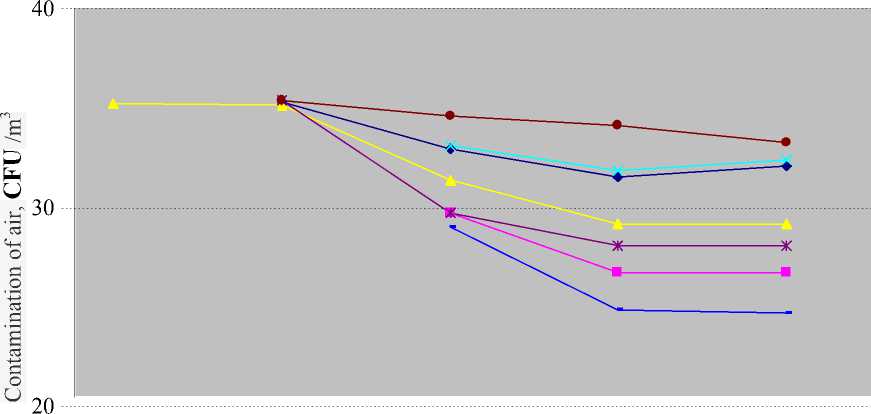

Production tests have shown that regular treatment of wall and floor with solutions of disinfectants based on QAC reduces the contamination of air spores molds and keeps it at a low level (Figure 1).

1 7 14 21 28

|

—♦ Control |

—■— Nika-2 |

Divosan- forte |

mixture of chlorine |

|

^ Vapusan 2000 |

—•— Deohlor-t |

Bior-1 |

■ Smorodinka |

Figure 1. - The number of viable cells of microorganisms in the air after treatment wall and floor with disinfectant solution based on QAC.

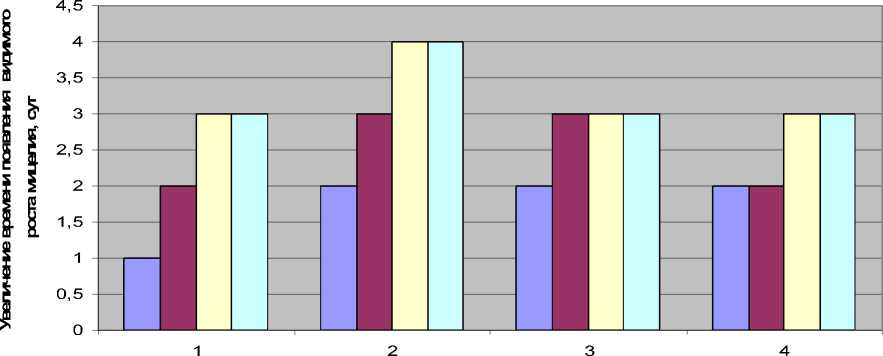

As a consequence increased the stability of the microbiology of produced bakery products. Increasing the time of appearance of visible growth of mycelium on the surface of the loaves threaded in industrial premises treat-ed by solutions of disinfectants based on QAC compared to control is shown in Figure 2.

продолжительность обработки, сут

□7□ 14 □ 21 □ 28

Figure 2 - Effect of disinfection of production facilities for microbiological stability during storage loaves threaded.

-

Y- Increasing the time of appearance of visible growth of mycelium, day

-

X- duration of treatment, day

Conclusion

-

1. Developed the optimal modes of use in the bakery industry enterprises of aqueous solutions of the following disinfectants: “Divosan-forte”, “Samarovka”, “Nick-2”, “Vapusan-2000”, “Deohlor-tablets”, “Bior-1”.

-

2. It is shown that a daily treatment of walls and floors with aqueous solutions of disinfectants based on QAC reduces the number of fungi on the surfaces of the floor is about 1000 times, the walls -more than 100 times, in the air of production facilities - 3-6 times. In addition, due to the formation fungicidal microfilm, contamination of air and surface production facilities remains low.

-

3. It is proved that regular disinfection treatment increases the production facilities of the visible appearance of mycelial growth on the surface of the bread for 1 - 4 days.

Список литературы Microbiological cleanliness of production areas is the way to microbiological stability of bread in storage

- Azarov V.N. Fundamentals of microbiology and food hygiene. -M.: Economy, 1981.-216 p.

- Arkadieva Z.A., Bezborodoye A.M., Blokhina I.N., etc. Industrial Microbiology. -M.: Vysshaya shkola, 1989. -688 p.

- Bogatyreva T.G., Sidorova O.L. Ways to improve the microbiological cleanliness of bakery and pasta products, methods of control. -M.: CNIITEIkhleboproduktov, 1994. -40 p.

- Verbina N.M., Kaptsreva Y.V. Micro-biology of food production. -M.: Agropromizdat, 1988. -255.

- Myuller E., Loeffler W. Mycology. Tran-slated from the German. -M.: Mir, 1995. -343 p.

- Polutornova T.N. Hygiene and sanitary food processing unit. -M.: Food prom-st, 1979.-358 p.