Obtaining cheese brynza with carrot

Автор: Abdizhapparova B., Khanzharov N., Orymbetova G., Khamitova B.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Техника и технологии

Статья в выпуске: 4 (125), 2019 года.

Бесплатный доступ

The article is devoted to the problem of expanding of assortment of brine cheeses with low caloric content. The solution of the problem is proposed by developing a technology of cheese brynza with vegetable fillers. A recipe and technology for cheese brynza with carrot was developedwith optimal ratio of 90:10. Experimental samples of cheese brynza with the vegetable filler were obtained. Physical and chemical and sensory indicators of the prepared cheese samples are determined. By means of scanning electronic microscope an elemental composition of obtained samples of brynza is determined.

Brynza, carrot, technology, filler, cheese, brine, milk

Короткий адрес: https://sciup.org/140249056

IDR: 140249056 | УДК: 637.33

Текст научной статьи Obtaining cheese brynza with carrot

Cheese products are becoming increasingly popular among consumers. The number of research and technological developments aimed at improving the range of cheeses and cheese products has increased significantly last days. Brynza is a cheese with a delicate or mild dense texture and moderately expressed cheese and salty taste. The taste and consistency of the product are stipulated by the original technology. It is produced from pasteurized cow, goat and sheep milk with the adding lactic acid starter streptococci and sticks, calcium chloride and following rennet coagulating [1]. The cutting surface is smooth, uniform, with a small quantity of eyes.

Brynza is considered to be the most useful of all types of cheese, it is rich in B group vitamins, A, E, trace elements, as well as minerals: potassium, calcium and fluorine salts. In addition, brynza is a valuable source of protein.

According to the content of calcium, which is necessary for the bones and teeth of each person, brynza exceeds whole milk and cottage cheese. It should be noted that the calcium contained in the cheese is fully absorbed by the body, so 70-100 grams of this product can provide the body's daily need for this microelement. In addition, brynza improves digestion and inhibits the development of putrid bacteria in the intestine.

Scientific research for brynza is devoted to the study of its rheological properties, the influence of packaging on its maturation and preservation, as well as its enrichment by introducing a complex of vitamins and vegetable base.

So, Zelensky V. A. and Korotkiy I. A. researched peculiarities of maturation of soft brine cheeses in plastic wrap (Armenianbrynza, Ossetian cheese). The use of polymer film during maturation and storage of the studied types of cheeses contributed to the preservation of the product, significantly reduced its shrinkage [2]. The authors found that the maturation and storage of the studied cheeses in the polymer film activate biochemical and microbiological processes and contribute to an increase in nitrogen fractions, as well as a longer preservation of their organoleptic characteristics.

Derevyanko N. P. and Semenova A.D. investigated production of brynza with addition of a vitamin complex (a, E, B1, B2, B6, B12, C, folic acid, rutin, nicotinamide). The authors studied the features of the preliminary preparation of components for the production of brine cheese and the method of adding vitamins. It is established that organoleptic properties of brynza with a vitamin complex do not differ from standard requirements, and introduction of a vitamin complex improves sensory characteristics of brynza. It is shown that the vitamin complex has a positive effect on the separation of serum from cheese [3].

Sysoeva M. G. and others developed the technology of cheese product "Brynza" with applying of amaranth flour (figure 1.8) [5].

It is known that the amino acids of amaranth flour are better balanced than wheat flour. Biological value of amaranth grain proteins is 15-18 % higher than that of wheat [6-9]. A unique feature of the lipid composition of amaranth flour is the presence of antioxidant squalene, as well as phytosterols, phospholipids and other compounds with biological activity. From mineral substances it is rich in calcium, potassium, magnesium, phosphorus, iron, vitamins Bi, B2, B9, C, PP, E, H [7]. Amaranth flour has a high water-holding capacity, so in the production of soft cheese it is advisable to use it as a natural thickener and stabilizer.

Amaranth flour with high protein content, amaranth flour of 1st grade and fat-free oilseed meal were used. The influence of the mass fraction of amaranth flour in the plant-milk mixture on the duration of protein coagulation, the dynamics of acidity increase in the cheese mass was studied. The best organoleptic characteristics had a cheese product at a dosage of amaranth flour with a high protein content of 2.5 %. It is established that within 9 days of storage the product by organoleptic and microbiological indicators met the established requirements. Using of amaranth flour with high protein content as a vegetable component in the production of cheese products is advisable, as there is a positive impact on the economic performance of production and nutritional value of the finished product.

Vegetables are applied in technology of soft cheeses and cheese products in view dry powder, i.e. topinambour, sterilized puree, i.e. carrot[10].

Blehjzi Nejl D. and others have developed a method for the manufacture of cheese and cheese products, which allows preserving the organoleptic and physical properties of cheese during its long-term storage, as well as reduce the time of the technological process of cheese and reduce its cost. The method includes the following stages: a) concentration of milk or reduced milk powder concentrate having a pH adjusted to the approximately level of 5.0 to 6.8, by ultrafiltration and diafiltration to obtain a retentate; b) adding a protein concentrate or isolate to mentioned retentate; c) heating the mixture to obtain a uniform consistency. This method does not require bacterial fermentation to obtain the optimal pH or consistency of the desired cheese, milk coagulating enzyme. The method is fast and takes less than 30 minutes [11].

At the same time, the issue of reducing the caloric content of cheese is relevant, which can be solved by replacing the milk base with plant components. In the conditions of the Turkestan region, the development of new types of cheese with the introduction of local vegetable raw materials as an additive is relevant.

Objects and methods of research

In accordance with the task, experimental studies were carried out in the laboratories of the Department of Food engineering, the regional laboratory of engineering profile "Structural and biochemical materials" of M. Auezov South Kazakhstan State University. Cheese brynza with vegetable filler carrots was chosen as the object of study.

Materials

Cow's milk, calcium chloride, Meito enzyme and carrots were applied to brynza.

Milk for production brynzashould have a clean taste and smell, to be without outsiders, not peculiar to fresh milk flavors and smells. In appearance and consistency, it should be a homogeneous liquid without sediment and flakes, color from white to slightly yellow. Raw milk possess by peculiar physical-chemical and hygienic characteristics.

Calcium chloride. The addition of calcium chloride in pasteurized milk is a mandatory operation, since pasteurized milk slowly coagulates under the action of milk-clotting enzymes and does not form a dense clot, whey from cheese grains is poorly separated. At pasteurization a part of calcium salts passes from the soluble to the insoluble state. Calcium chloride to a certain extent restores the original salt composition of milk, broken during pasteurization, and improves rennet coagulation of milk.

Carrotroots should have a cylindrical or elongated-conical shape, smooth surface, delicate, juicy consistency of pulp, orange-red or intense orange color with a brightly colored core, a well-expressed flavor, preserved in the finished product.

Plant milk-converting enzyme Meito (pepsin) (Japan) is a specific protease, which in its amino acid composition is identical to the veal rennet enzyme. But Meito at the same time does not contain animal and chemical components, which favorably affects the shelf life and taste of cheese.It is produced by fermentation and further drying of plant edible fungus Mucorpusilus and Misogmiehei. Proteases enzymes from fungi clot milk to form a curd [12, 13].

The enzyme is included in the RF national standard - GOST 52686-2006 "Cheese. General specifications».

Normative documentation

The following modern methods to determine the characteristics of raw materials and finished products were applied:

-

- GOST R 53104-2008 "Method of organoleptic evaluation of the quality of public catering products»;

-

- GOST 3622-68 “Milk and dairy products. Sampling and preparation for testing”;

-

- GOST 3626-73 “Milk and dairy products. Methods for determination of moisture and dry matter”;

-

- GOST 3628-78 “Dairy products. Methods of sugar determination;

Devices

The following devices to determine the characteristics of raw materials and finished products were applied:

-

- milk analyzer "Clever-2" - to determine the temperature, SOMO, fat, protein and density of cow's milk;

-

- scanning electron microscope (SEM) – for analysis elemental composition of researched product [14].

Technological scheme

The technological process of preparation of brynza consists of the following operations:

-

- preparation milk for cheese production: quality control and sorting of milk; reservation of milk; milk maturation; normalization; heat treatment; vacuum treatment; ultrafiltration of milk;

-

- preparation of milk for coagulation: introduction of calcium chloride into milk; introduction of potassium or sodium nitrate into milk; application of bacterial starter cultures and concentrates;

-

- production and processing of clot: coagulation of milk; processing of clot and cheese grain;

-

- molding the cheese; cheese self-pressing; cheese salting; ripening of cheese [15-17].

Results and discussion

milkcarrots

treatment of clot (cutting on cubes by size 15…20 mm and holding during 10…15 min)

removing of whey (65...70%)

salting (300 g salt for 100 kg milk, holding 25...30 min))

salting (18...20 %-th solutionof brine,10...12 0С, 5-7 days)

holding in 18%-thsolutionof brine (13...15 days, 8-120С )

maturation in 18%-thsolution of brine (8-100С)

packing storage in cooled view

Figure1 -Technological scheme of cheese brynza with carrots.

The results of the study of physical and chemical parameters of cow milk on the analyzer "Clover-2" are shown in table 1.

Table 1 – Physical-chemical indicators of cow milk

|

Temperature |

10,0ºС |

|

SOMO |

7,6 % |

|

Fat |

3,2% |

|

Protein |

3,0%, |

|

Density |

1027 kg/m3 |

The developed technological scheme for the production of cheese brynza with the vegetable filler is shown in figure 1.

All experimental samples of cheese brynza with carrots were exposed to organoleptic analysis on such indicators as appearance, taste, consistency and smell (aroma). 5 tasters participated in sensory evaluation. The tasting was conducted in compliance with all accepted norms [18] and GOST R 53104-2008 "Method of organoleptic evaluation of the quality of products for public catering".

Initially, the organoleptic characteristics of the cheese with the vegetable filler were determined in order to determine the optimal amount of carrots. For this purpose, the ratio of the cheese mixture and the vegetable filler in the ratio from 98:2 to 80:20% was varied. At the ratio of brynza and carrots 90:10 there are high values of all organoleptic characteristics. Organoleptic characteristics of brynza with carrots at a ratio of cheese mass and carrots 90:10 are shown in table 2.

Table 2 – Sensory indicators of cheese brynza with carrots

|

Name of product |

Sensory indicators |

|||

|

appearance |

taste |

consistency |

smell, aroma |

|

|

Brynza with carrot |

Round flattened bar. A homogeneous mass with a creamy color and orange inclusions |

Clean, sour milk, with a slight taste of carrots |

Soft plastic, slightly brittle. Few quantity of small eyes |

Moderately expressed cheese |

The values of physical and chemical parameters and energy value of the cheese with the vegetable filler are given in tables 3 and 4. As can be seen from table 3, obtained samples of brynzawith the vegetable filler contain more moisture, less protein and fat, which is explained by the partial replacement of raw milk by carrots.

Table 3 - Physical-chemical parameters of brynza with carrots

|

Determined component |

Experimental data, % |

Reference data, % [19] |

|

Brynza with carrots |

Brynza from cow milk |

|

|

Moisture, % |

53,0 |

52,0 |

|

Proteins, % |

17,1 |

17,9 |

|

Fats, % |

17,5 |

20,1 |

|

Carbohydrates, % |

5,0 |

- |

|

Ash, % |

7,4 |

8,0 |

Table 4 – Energetic value of brynza with carrots

|

Product |

Energetic value, kJ/kcal |

|

Brynza with carrots |

1029,58/245,9 |

At comparisona reference data of caloric content of brynza from cow's milk-260 kcal [19] with experimental data it can be concluded that the energy value of the samples is below.

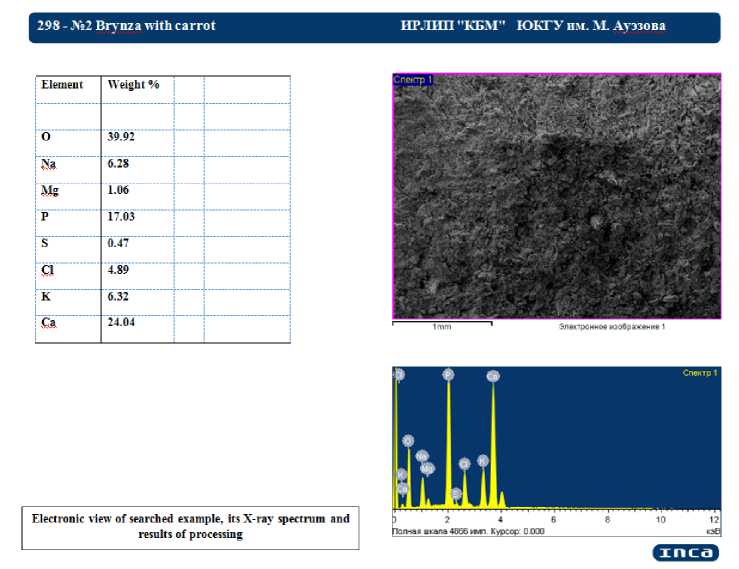

By means of scanning electron microscope an elemental composition of brynza with vegetable fillers is determined (figure 2). As it seen from results of analysis there are such minerals as sodium, magnesium, phosphorus, potassium and calcium in sufficiently great quantities.

Figure 2 - Electronic view of the brynza with carrots, its X-ray spectrum and results of processing

Conclusions

-

1. The technology of production of brine cheese brynza with carrot is developed.

-

2. Experimental samples of cheese brynza with carrot as a vegetable filler represent a round flattened bar, on a section - a homogeneous mass of cream color with orange inclusions. Taste is sour milk, with a little taste of carrot. Smell is mild cheese. The consistency is soft, plastic, slightly brittle.

-

3. The formulation of brynza with vegetable fillers was developedon the basis of organoleptic analysis: the optimal ratio of cheese mass and carrot - 90:10.

-

4. In comparison with traditional brynza the received samples are differed in the reduced caloric content.

-

5. By means of scanning electron microscope the elemental composition of brynza with vegetable fillers was determined.

-

6. The actual issue is the decreasing calorie content of cheese can be solved by the replacement of a dairy basis by vegetable components.

-

7. In the development of new types of cheese in southern Kazakhstan it is advisable to use local vegetable raw materials. For cheese, it is better to use vegetable fillers which are well combined with the taste of cheese.

Список литературы Obtaining cheese brynza with carrot

- Florinskaya E. A., Nikolaeva S. L. Expertise of quality of brine cheeses of Russian and foreign manufacturers // Scientific notes of V. B. Bobkov St. Petersburg branch of the Russian customs academy. -2015. - No. 1 (53) - P. 73-86. [in Russian]

- Zelensky V. A., Korotkiy I. A. Influence of packing of soft brine cheeses in a polymeric film on maturation and quality of a product // Technics and technology of food productions. -2011. - No. 3 (22).- P. 58-61. [in Russian]

- Derevyanko N. P., Semenova A.D. Production of cheese with vitamin complex / Scientific Bulletin of Lviv national University of veterinary medicine and biotechnology named after S. Z. Gzhitsky. -2016.- Vol. 18, No. 1-3 (65). P. 44-48. [in Ukrainian]

- Skulskaya I.V., Tsisaryk O.I. Study of structural and mechanical parameters of cheese at partial replacement of table salt with potassium chloride // Lviv national University of veterinary medicine and biotechnology named after S. Z. Gzhitsky. - 2016. - Vol. 18, No. 2-3 (68) - P. 99-102. [in Ukrainian]

- Sysoeva M. G., Glotova I. A., Aristova A.V., Pronina E.A., Polenov I.V., Smolskaya L.G. Substantiation and development of technology of cheese product using amaranth flour // Technologies of food and processing industry of agroindustrial complex products of healthy nutrition. -2017. - No. 5 (19). P. 64-72. [in Russian]

- Zharkova I. M. Amaranth flour - an effective tool for the production of healthy foods. Khleboprodukty. - 2012. - No. 12. P. 54-56. [in Russian]

- Polymorphism of RAPD- and ISSR-markers in grain species of amaranth [Text] / S. V. Limanskaya, A. A. Miroshnichenko, T. I. Goptsov, O. S. Korneeva// Vavilov journal of genetics and breeding. -2017.-Vol. 21, No. 2. - P. 189-197. [in Russian]

- Sysoeva M. G. Technology of production of cheese product with addition of vegetable protein [Text] / M. G. Sysoeva, A.V. Pronina // Technologies and merchandising of agricultural products. -2015. - No. 1 (4). - P. 21-25. [in Russian]

- Shmalko N. A. Amaranth in food industry [Text] / N. A. Shmalko, Yu. F. Roslyakov. - Krasnodar: Prosvescheinie-Yug, 2011. - 489 p. [in Russian]

- Yakovchenko N. V. Obtaining soft rennet cheeses from ultrafiltration milk concentrate with the addition of vegetable fillers [Text] /N.V. Yakovchenko, A. A. Silantieva // Izvestiya vuzov. Food technology. - 2010. - No. 6. - P. 35-37. [in Russian]

- Patent of Russian Federation. 2270571. Method for cheese and cheesy foodstuff production / Blehjzi Nejl D. (US); Dajbing Stefen T. (US); Khuangi-Lo (US); Najts Ral΄f Dzh.; Publ.27.02.2006. [in Russian]

- Vickie A.Vaclavik, Elizabeth W.Christian. Essentials of food science. - Springer: 2008. - 571 p. [in English]

- Vickie A.Vaclavik, Elizabeth W.Christian. Essentials of food science. 4th edition - Springer: 2014. - 495 p. [in English]

- Scanning electron microscopy for nanotechnology. Methods and applications // ed.by Milieu and Zhong Lin Ouanga: translation from English. - M.: Binom. Knowledge laboratory, 2013. - 582 p. [in Russian]

- Krus G.N. et al. Technology of milk and dairy products/G. N. Krus, A. G. Khramtsov, Z. V. Volokitina, S. V. Karpychev; ed. By Shalyina A.M. - Moscow: Koloss, 2006. - 455 p. [in Russian]

- Food Processing Handbook / Edited by James G. Brennan and Alistair S. Grandison. Volume 1, 2012 Wiley-VCH Verlag& Co. KGaA. [in English]

- R. Paul Singh, Dennis R. Heldman. Introduction to Food Engineering // Elsevier, Fourth Edition, 2009. - 841 p. [in English]

- Awad, R. A., El-Shabrawy, S. A., Osman, S. G. & Saad, S. A. Chemical composition of flavoured processed cheese spreads with different fruit flavours // Egyptian Journal of Dairy Science. - 2003.- Volume 31 - P. 235-344. [in English]

- Chemical composition of food products: Book 1: Reference tables of the content of basic nutrients and energy value of food products / ed. by prof., Dr. of med. sciences I.M. Volgarev. - 2nd ed., processed and supplemented.-M.: VO "Agropromizdat", 1987. - 224 p. [in Russian]