Preparation of textile materials for dyeing and printing

Автор: Dyussenbiyeva К.Zh.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 4 (146), 2024 года.

Бесплатный доступ

The article presents data on the development of technology for the preparation of cotton fabrics for subsequent coloring processes and final finishing. Improving the quality of products in the process of preliminary preparation of fabrics is associated with the development of highly efficient technologies using textile auxiliaries, new chemical and physical methods for intensifying ongoing processes. Technologies have been developed for the preparation of cotton fabrics aimed at obtaining the required level of physical and mechanical characteristics of materials. The optimal parameters for the preparation of technological solutions, concentrations of chemicals, the ratio of components in the solution, temperature and duration of the process were selected. The qualitative parameters of the treated tissue, capillarity, degree of whiteness, and discontinuity characteristics were studied. A periodic and continuous method of preparing cotton fabrics is proposed, ensuring the removal of non-fibrous impurities from harsh fabrics, which will improve the quality of the treated fabric by increasing capillarity and whiteness, reduce energy consumption and duration of the process. The obtained research allows us to build modern and promising, economically justified technological processes for the preparation of textile materials made from natural, chemical fibers and their mixtures.

Textile materials, concomitant impurities, textile auxiliaries, finishing preparations, technological processes of preparation, decoction, bleaching, final finishing of textile materials, consumer characteristics

Короткий адрес: https://sciup.org/140308687

IDR: 140308687 | DOI: 10.48184/2304-568X-2024-4-171-176

Текст научной статьи Preparation of textile materials for dyeing and printing

МРНТИ 64.29.23

Preparation of fabrics for dyeing and printing is a set of processes that ensure the removal of non-fibrous impurities from harsh fabrics in order to give them the ability to quickly and evenly wet with water and stable whiteness. The substances to be removed include natural impurities that accompany natural fibers, and chemical materials applied to fiber and yarn in the processes of their manufacture and processing. For fabrics made of natural fibers, such materials include natural cellulose satellites, oilers and dressings, residues of fatty and sweat substances, cellulose impurities, sericin, waxy substances, fatty emulsions and soaps applied before twisting and weaving [1-3].

Harsh fabrics containing these impurities are poorly wetted with water, it is almost impossible to get bright, uniform, saturated and durable colors on them. In the process of preparing fabrics for dyeing and printing, it is necessary to free the surface and pores of the fibrous material for subsequent interaction with the dye and auxiliary materials, to remove internal stresses that cause uneven properties, while the physico-mechanical and chemical properties of the fiber must be preserved [4-6].

At the same time, chemical reagents and textile auxiliaries used in preparatory operations should not cause the destruction of cellulose. In this regard, it is necessary to know the structure and properties of non-cellulose impurities, which must be destroyed and removed during the preparation of cotton materials [7-9].

Currently, training is carried out on continuously operating equipment or on high-performance batch machines. To increase labor productivity, separate operations are combined in the preparation of textile materials. However, in this case, it must be remembered that the properties of textile materials do not deteriorate.

The preparation of fibrous materials for dyeing and printing is a complex process and involves a large number of operations. Technological processes and equipment for chemical purification of fibrous materials are determined by the nature of impurities and the strength of their bond with the fiber, the chemical, physico-chemical structure of the fiber and its properties.

The process of preparing cotton products for dyeing and printing should be carried out under quality control, so that when the best whiteness and maximum capillarity are achieved, the cellulose is damaged as little as possible, in this regard, the development of technology for preparing cotton textile materials for dyeing and printing is an urgent scientific task [10,11].

Materials and research methods

The cotton fabric was boiled according to a periodic method in a 400 ml bath module: NaOH -10 g/l, Na2SiO3∙nH2O- 5 g/l, ОР-10 - 2 g/l, NaHSO3- 10 g/l. After preparing the solution at a temperature of up to 40-50 °C, we place the samples, then raise the temperature to 80 °C and boil for 30 minutes. We wash the tested samples, squeeze them out and proceed to the next bleaching process. At the first stage of processing, the fiber swells and adsorbs caustic soda, then chemical reactions of caustic soda with impurities occur. As a result of hydrolysis, pectin substances pass into soluble compounds and are completely removed from the fiber. Nitrogen-containing protein substances are hydrolyzed to form amino acids, which, with caustic soda, give water-solu-ble salts. The remaining waxy substances are re-moved by emulsification using surfactants. The bleaching process was carried out in a 400 ml bath module: NaOH-5 g/l, Na2СО3- 2,5 g/l, Na2SiO3∙nH2O – 7,5 g/l, H2O2- 30-40-50 g/l. Bleaching at a temperature of 90 oC for 30 minutes. Next, washing, pressing and drying.

The cotton fabric was boiled and bleached using a continuous method in a 400 ml bath module: NaOH-12 g/l, Na 2 SiO 3 ∙nH 2 O – 7,5 g/l, ОР-10 - 2 g/l, NaHSO 3 -10 g/l, H 2 O 2 - 30-40-50 g/l. The temperature is 90 °C, the time is 30 minutes. The processed samples are washed, squeezed and dried.

Results and discussion

The main indicators characterizing the quality of prepared textile materials are: capillarity, whiteness and degree of damage to cellulose.

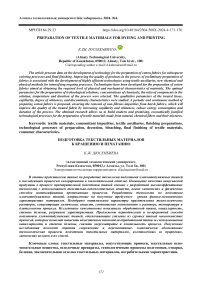

Periodic and continuous methods of preparing cotton fabrics have been developed. The results of the studies are shown in Table 1 and Figure 1.

Table 1. Indicators of bleaching of samples treated in a periodic and continuous method

|

№ Boiling process |

NaOH-10 g/l, Na 2 SiO 3 -5 g/l, ОP-10-2 g/l, NaHSO 3 -10 g/l |

|

1 Вleaching process |

NaOH-5 g/l, Na 2 СO 3 -2,5 g/l, Na 2 SiO 3 -7,5 g/l. H 2 O 2 -30 g/l H 2 O 2 -40 g/l H 2 O 2 -50 g/l Whiteness, % 87,8 88,5 92,8 |

|

2 Boiling and bleaching process |

NaOH 12 g/l, Na 2 SiO 3 7,5 g/l, ОP-10 - 2 g/l, NaHSO 3- 10 g/l H 2 O 2 -30 g/l H 2 O 2 -40 g/l H 2 O 2 -50 g/l Whiteness, % 89,5 90,2 90,7 |

|

3 Raw material |

69,04 |

необр-raw material

1п- H 2 O 2 – 30 g/l

необр-raw material

Ic- H 2 O 2 – 30 g/l

2п- H 2 O 2 - 40 g/l

3п- H 2 O 2 – 50 g/l

IIc- H 2 O 2 – 40 g/l

IIIc- H 2 O 2 – 50 g/l

Figure 1. Comparison of the whiteness of cotton textile materials

According to the results of the study using the periodic method, the whiteness of cotton fabrics was 92,8 %, according to the continuous method 90,7 %, and the harsh sample was 68 %. In accordance with the requirements of the standards, the whiteness of linen fabrics should be at least 80 %, and for improved varieties – 83 %, the whiteness of magpie fabrics should be 87- 88 %.

Based on experimental data, it was found that the preparation of cotton fabrics according to the proposed methods leads to an increase in the whiteness index in accordance with the requirements of GOST 18054-72 [12,13].

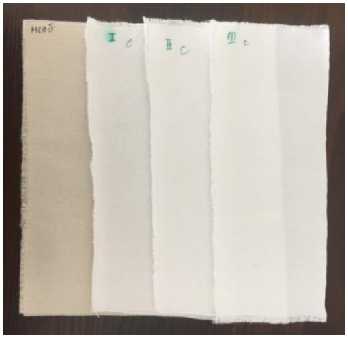

The results of determining the capillary properties of cotton fabrics are presented in Table 2 and Figure 2.

Table 2. The effect of treatment and concentration of solutions on the capillary properties of cotton fabric

|

№ |

Time, min |

Raw material |

Capillary properties, h, cm |

|||||

|

periodic method |

continuous method |

periodic method |

continuous method |

periodic method |

continuous method |

|||

|

H 2 O 2 -30 g/l |

H 2 O 2 -40 g/l |

H 2 O 2 -50 g/l |

||||||

|

1 |

15 |

1 cm |

11,5 cm |

10,5 cm |

12,0 cm |

10,7 cm |

12,6 cm |

10,9 cm |

|

2 |

30 |

13,6 cm |

12,9 cm |

14,9 cm |

13,2 cm |

15,5 cm |

13,3 cm |

|

|

3 |

45 |

14,7 cm |

14,7 cm |

17,0 cm |

15,2 cm |

17,2 cm |

15 cm |

|

|

4 |

60 |

15,5 см |

15,8 см |

18,1 см |

16,4 см |

18,2 см |

16,2 см |

|

необр-raw material

необр-raw material

1п- H 2 O 2 – 30 g/l

2п- H 2 O 2 – 40 g/l

3п- H 2 O 2 – 50 g/l

Ic- H 2 O 2 – 30 g/l

IIc- H 2 O 2 – 40 g/l

IIIc- H 2 O 2 – 50 g/l

Figure 2. Determination of capillarity of cotton textile materials

According to the results of studies of the capillary properties of cotton fabrics, where OP-10 was used as a textile auxiliaries, capillarity indicators reached h = 18.2 cm using the periodic method, h = 16.2 cm using the continuous method at a concentration of H2O2 = 50 g/l. At a concentration of H2O2 = 30 g/ l, the capillarity indices according to two methods were h = 15.8 cm, in contrast to the harsh sample h = 1 cm. This is due to the fact that the textile auxiliaries in the preparation process contributed most to the removal of the main part of the natural satellites of natural fiber and substances deposited on textile fibers during their processing [14].

The determination of the tensile properties of cotton fabrics was carried out according to GOST 3813-72 [15]. The results of the studies are presented in Table 3.

Table 3. Indicators of the absolute breaking load of samples according to the periodic and continuous method

|

№ |

Breaking load, F (Н) |

||||||||

|

1 |

H 2 O 2 |

weft |

warp |

||||||

|

periodic method |

continuous method |

periodic method |

continuous method |

||||||

|

F (Н) |

L (mm) |

F (Н) |

L(mm) |

F (Н) |

L (mm) |

F (Н) |

L (mm) |

||

|

30 g/l |

391 |

44,51 |

371 |

54,70 |

266 |

23,79 |

268 |

23,77 |

|

|

40 g/l |

372 |

42,98 |

385 |

50,26 |

279 |

53,52 |

244 |

27,32 |

|

|

50 g/l |

402 |

46,89 |

369 |

42,56 |

271 |

59,03 |

266 |

44,63 |

|

|

2 |

raw material |

344 |

46,79 |

344 |

46,79 |

286 |

30,84 |

286 |

30,84 |

It can be seen from the data that the breaking load of the continuous method decreases slightly with an increase in the concentration of H 2 O 2 = 50 g/l. In the periodic method, the discontinuous characteristics do not decrease with an increase in hydrogen peroxide.

Сonclusion

The preparation process was carried out according to periodic and continuous methods. According to the periodic method, the whiteness of cotton fabrics was 92,8%, according to the continuous method 90,7%, and the harsh sample was 68 %. In accordance with the requirements of the standards, the whiteness of linen fabrics should be at least 80 %. The capillarity indices were reached by the periodic method h = 18,2 cm, by the continuous method h = 16,2 cm at a concentration of H 2 O 2 = 50 g/l. At a concentration of H 2 O 2 = 30 g/l, the capillarity indices according to two methods were h = 15,8 cm, in contrast to the harsh sample h = 1 cm. The breaking load of the combined method decreases slightly with an increase in the concentration of hydrogen peroxide to 50 g/l. In the periodic method, the discontinuous characteristics do not decrease with an increase in hydrogen peroxide. According to the results of the study, an optimal combined method for the preparation of cellulose textile materials with a concentration of components was found: NaOH=12 g/l, Na 2 SiO 3 =7,5 g/l, OP-10=2 g/l, NaHSO 3 =10 g/l, H 2 O 2 =40 g/l. With a continuous method, the processing process is more economical both in terms of labor productivity and in terms of removing products from 1 m2 of production area.

Gratitude, conflict of interest (funding)

The work was carried out at the Almaty Technological University. The author declares that there is no conflict of interest.

Список литературы Preparation of textile materials for dyeing and printing

- A.K. Roy Choudhury, “Green Chemistry and the Textile industry”, Text. Prog, 45(1), (2013): pp. 3-143.

- Красина И.В. Химическая технология технических материалов [Электронный ресурс]: Учебное пособие / Красина И.В., Вознесенский Е.Ф.- Казань: Казанский национальный исследовательский технологический университет, 2014 г.- 116 с.- ISBN 978-5-7882-1600-3

- T. Wright, A. Mahmud-Ali, T. Bechtold. “Surface coated cellulose fibers as a biobased alternative to functional synthetic fibers”, Journal of Cleaner Production, Volume 275, article number 123857, (2020).

- I. Zerin, N. Farzana, A.S.M. Sayem, D.M. Anang, J. Haider, “Potentials of natural dyes for textile applications, in Encyclopedia of renewable and sustainable materials”, vol. 2, 1st edn., ed. by I. Choudhury, S. Hashmi (Elsevier Science, Amsterdam, 2020), pp.873–883

- R. Repon, M. T.Islam, A. Al. Mamun, M. A. Rashid, “Comparative study on natural and reactive dye for cotton coloration”, Journal of applied research and technology. Versión On-line ISSN 2448-6736, vol. 16, № 3 (2018).

- Скобова Н. В., Ясинская Н. Н., Козодой Т. С. Интенсификация процесса крашения шерстяных волокон, Вестник Витебского государственного технологического университета, 2018.- № 1(34).- С. 103–108.

- Ясинская Н. Н., Скобова Н. В. Применение ферментных препаратов для подготовки хлопчатобумажных и смесовых тканей. //Известия высших учебных заведений. Технология легкой промышленности, 2018.- Т. 40.- № 2.-С. 58–62.

- F.H.H. Abdellatif, M.M. Abdellatif, “Utilization of sustainable biopolymers in textile processing, in Green chemistry for sustainable textiles: modern design and approaches”, 1st edn., ed. by N. Ibrahim, C.M. Hussain, (Elsevier Science, Amsterdam, 2021), p. 453–467

- L. Jajpura, A. Rangi, A. Khandual, “Natural finishes, technologies and recent developments, in Sustainable technologies for fashion and textiles”, 1st edn., ed. by R. Nayak (Woodhead Publishing, Cambridge, 2020), pp.209–229

- K. M. Zaman, Zia, M. Zuber, “Preparing Delicate Cellulose Fabric by Utilizing Polyacrylamide Softener to Enhance Surface Smoothness and Quality Properties,” International Journal of Sciences: Basic and Applied Research, Volume 23, No 2 (2015), pp. 396-406.

- S. A. Rahman, A. B. M. Foisal and A. Sarker, “Treatment of Cotton Fabric with Cationic Polyacrylamide – An Initiative to Salt Free Reactive Dyeing”, SEU Journal of Science & Engineering, Vol. 9, No. 1-2, December (2015).

- ГОСТ 7138-83. Ткани хлопчатобумажные миткалевой группы. Технические условия.

- ГОСТ 18054-72 (ISO 105-J02-87) Материалы текстильные. Метод определения белизны.

- ГОСТ 3816-81 (ISO 811-81) Полотна текстильные. Методы определения гигроскопических и водоотталкивающих свойств.

- ГОСТ 3813-72 (ISO 5081-77, ISO 5082-82) Материалы текстильные. Ткани и штучные изделия. Методы определения разрывных характеристик при растяжении.