Research of physical and mechanical properties of knitted fabrics of plush interlooping with reduced material consumption

Автор: Sarybayeva E.E., Kuramysova M.U., Jurinskaya I.M.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 1 (143), 2024 года.

Бесплатный доступ

The article discusses methods for manufacturing lined weave plush knitwear and ways to reduce the material intensity of knitted fabrics. The purpose of the study is to reduce the material consumption of products while maintaining operational, hygienic and aesthetic properties in the production of knitted fabrics. As a result of experimental work, the technological capabilities of the KН-323D flat knitting machine were studied and new types of lined weave plush knitwear were developed. Comparing the bulk density of plush knitwear with elongated lining broaches with the main base weave, it is clear that the presence of elongated lining broaches in the knitwear structure increases the thickness of the knitwear and reduces the bulk density. The breathability of a lined weave plush jersey is significantly less than that of a basic weave. It has been established that air permeability coefficients can be reduced to 33.1% (46.3-66.9 cm3/cm2∙sec) by adjusting the length of the threads of the lining broaches of plush knitted fabric of lined weave. Regression equations are derived to determine the dependence of bulk density, breaking load (along the length and width) and the air permeability index of knitted fabric on technological factors. Mathematical models were built in Excel using regression equations. The research results make it possible to improve the quality and consumer properties of knitted products, and to select advanced production technologies for their production.

Knitted fabrics, structure, plush interloping, footer broaches, volume density

Короткий адрес: https://sciup.org/140304535

IDR: 140304535 | DOI: 10.48184/2304-568X-2024-1-203-210

Текст научной статьи Research of physical and mechanical properties of knitted fabrics of plush interlooping with reduced material consumption

In modern conditions of market economy development and aggravation of competitive struggle the determining factors of successful activity of enterprises are their work on creation of new types of high-quality products, improvement and frequent renewal of product assortment, ability to quickly respond to market needs.

In recent years, more and more volume is occupied by knitted clothing, which can be explained by good consumer properties of knitted products and high technical and economic indicators of its production [1].

The relevance of the work is due to the solution of problems aimed at further development of the theory of weaves and methodology of synthesis (design) of new knitted fabrics, providing the possibility of significant expansion of the range of knitted fabrics, the introduction of modern design methods in the practice of knitwear production, ensuring the quality of knitted products. The work is also related to the development of new areas of knowledge aimed at improving the technology of knitted production, in particular, based on a systematic approach to the study and design of knitted weaves.

Nowadays in knitting production a lot of work is being done to reduce the consumption of textile yarns per unit of a product. The experience on creation of knitted fabric characterized by reduced material intensity has been accumulated. Therefore, the set task of development of rational structures and research of properties of lightweight knitted fabrics of pressed, combined and plush weaves for outerwear, as well as scientific substantiation generalizing practical experience is actual [2].

In knitwear production, the main tools are continuous innovative shifts in the field of expanding looping functions (Shima Seiki) and, as a consequence, the creation of new structures and new 3D knitting possibilities. Creation of new technologies using large diameter circular knitting machines with a wider range of thicknesses and types of yarn, increasing the class of machines up to 50 and reducing material intensity with increasing productivity (per day up to 250...400

kg), on the other hand, reducing the class to 1.5...2 for knitting of outerwear, household textiles [3].

In the theory of knitting, there is not enough scientifically grounded research summarizing practical experience, and in the published materials the features of structure and properties of knitted fabrics are studied mainly, but the meaning remains unexplored. The question of obtaining knitted fabrics with high consumer and hygienic properties and reduced material intensity is poorly studied.

Therefore, the purpose of the research work is to develop a systematic approach to the choice of methods of rational use of raw materials in the production of knitted fabrics with reduced material intensity through structural synthesis of lightweight variants of basic structures, providing the demand of the population with high-quality knitted products with improved hygienic and consumer properties and improving the technology of their production.

Мaterials and research methods

To expand the assortment of knitted fabrics and maximize the use of technological capabilities of flat-fanging machine type KN-323D 3 variants of structure and methods of production of plush knitted fabric of lined weave were developed, cotton yarn T = 20 tex x 3 was used as raw material.

A lined knitted fabric with a regular-length fouter broach was chosen as the base weave (Variant -1).

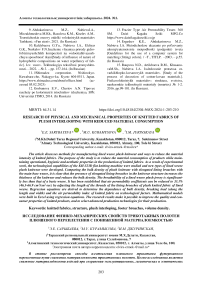

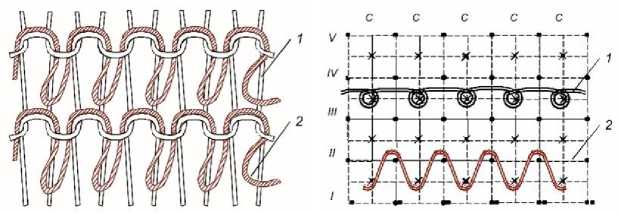

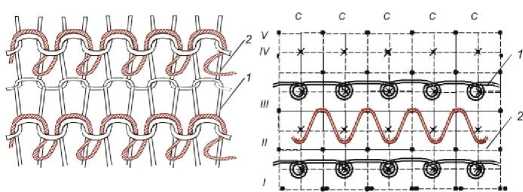

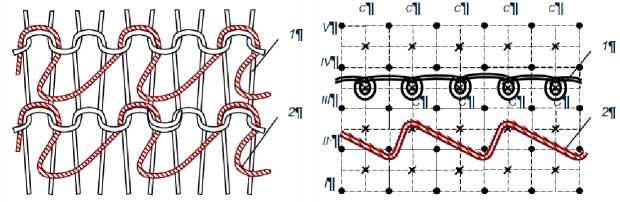

The structure and graphical recordings of II, III, and IV variants of the plush knitted lined weave are shown in Figures 1,2,3,. The knitted fabric consists of ground loops 1 and of elongated plush broaches 2.

Figure 1 - Structure and graphical recording of the II variant of the lined plush knitted fabric

All variants of the plush knitted fabric conditions: the tension, yarn culling depth, and interlooping were developed under the same pull-off force of the knitted fabric were the same.

Figure 2 - Structure and graphical recording of the III variant of the lined plush knitted fabric

The length of the fouter broaches in the knitted fabric is the same as that of the teddy, because during their formation the fouter thread is curled by the needles of another needle. Therefore, the resulting knitted fabric can be used without the pile operation.

Technological parameters, physical and mechanical properties of knitted samples were determined in accordance with the current standards: surface density of knitted fabrics, g/m2 ISO 7211-2, thickness - ISO 5084; breaking characteristics, ISO 3801, GOST 3813-72, GOST 8847-85; air permeability ISO 9237, humidity GOST 8845-87.

Figure 3 - Structure and graphical recording of the IV variant of the lined plush knitted fabric

Literature review.

Nowadays, the trend of using different weave structures to reduce material consumption is widely applied in the knitting industry. Many researchers both in our country and abroad are engaged in expanding the range and improving the quality of knitted products, creating new designs and effective methods of knitting knitted products with optimal parameters [4, 5, 6].

The advantages of plush knitted fabrics include the firm fixation of pile loops in the ground structure, the simplicity of producing fabrics with both loop and cut pile at high productivity of machines, the possibility of obtaining a variety of patterns.

Significant research in this field belongs to Prof. A.S. Dalidovich, Prof. I.I. Shalov, Prof. L.A. Kudryavin, Prof. F.A. Moiseenko, Prof. E.P. Pospelov, Prof. M.M. Mukimov and their students.

M.M. Mukimov [43], in order to reduce the consumption of raw materials, when producing plush knitted fabric of platting-fine weave with double-sided broaches, includes in the structure of the knitted fabric loop rows of smoothing. The surface density of the plush knitted fabric is reduced by changing the structure of the basic weave and the number of plush broaches on the surface of the fabric.

As a result of the conducted research the development of plush knitted fabric on the basis of incomplete weave expands the assortment of knitted fabrics, and the presence of elongated pressed sketches and stretches in the structure of knitted fabric increases the form stability of the fabric and reduces the consumption of raw materials in its production. The conducted researches in the field of form-stability of plush knitted fabrics have shown that it is necessary to use elastic yarns, especially as ground yarns, for the manufacture of form-stable knitted fabrics. The elasticity of yarns has a great influence on the form-fitting of knitted fabrics. The smaller will be the share of retarded processes (residual strain) in the total relaxation process of the yarn deformation, the greater will be the strain relaxation rate and the higher will be the share of its elastic strain [8].

Studies have established that the introduction of elements highly oriented in the stretch direction into the structure of the basic weave reduces the length and width, as well as decreases the surface density, and increases the strength of knitted fabric. The main properties that determine the stability of its properties under stretching include shrinkage, stiffness, irreversible and reversible deformations. It has been found that the introduction of jacquard and press loops into the knitted fabric structure and changing their number in the weave pattern increases the stability of plush knitted fabric [9].

In [10] the peculiarities of the technology of producing plush weave plaid knitted fabric with plated fixation of plush yarn on a flat knitting knitting machine using the process of looping without couching are considered.

Based on the study [11] of the ability of hybrid plush knitwear to absorb moisture, a three-layer structure of such knitwear with a "dryness effect" created by using hydrophilic and hydrophobic fibers is proposed. A material for the manufacture of hybrid plush knitwear, which allows the maximum realization of the moisture content limit with the "dryness effect", is recommended.

Scientists [12] have developed a technology for the production of three-, four- and five-weave knitted fabrics on a flat knitting machine of "Shima-Seiki" type (Japan). The results of research, worked out samples showed that depending on the weave rapport, increases the surface density of knitted fabric and its thickness compared to the basic weave (biclastic) with the same filling PAN 31tex x2.

The study of the fabrics produced on the round-turn machine SPG 10 kl., where cotton yarn of linear density 18.5 tex x4 is used as the priming yarn, showed that with increasing the percentage of press loops in the rapport of the double-fold weave from 7 to 25% the intensity of increase in the knitted fabric surface density gradually decreases, and the intensity of increase in the knitted fabric thickness increases [13].

There is a tendency to develop methods for predicting the structure and properties of woven fabrics at the preliminary design stage without resorting to the production of full-scale samples due to the high cost of the latter.

Computer modeling of double-sided plush allows to save time and create a high-quality design. Based on the basic analysis of jacquard principles, a method for fast 3D modeling of knitted plush fabrics using geometric method on a graphics processor was proposed [14]. In the following research work [15] a set of CAD system was developed in order to realize the rapid design of double-needle bar short pile fabric.

-

[16] research was aimed at selecting the most adequate designs for winter outerwear. Experimental work was carried out to determine the influence of different weave structures. As a result of variance analysis, it was found that the influence of the pile weave structure on the functional properties of knitted fabrics is quite significant. The results show that the air permeability is mainly affected by the woven structure parameters, but the change of processing parameters has a great influence on the wetting angle [17].

To realize the function of computer modeling of jacquard cotton fabric, a mathematical modeling method based on texture synthesis is proposed, and the basic model and principle of texture synthesis algorithm are studied [18].

Mayer produces circular knitting machines for producing plush knitted fabrics with reduced material intensity [50]. It is noted that plush fabric is versatile in terms of its application. It is used not only for the manufacture of fashion products, but also for the manufacture of sportswear, leisurewear, as well as a material for upholstery of furniture and car interiors.

Results and discussion

Experimental samples of knitted fabrics were developed on a flat knitting machine in order to compare new structures of cotton knitted fabrics in terms of physical and mechanical properties. The physical and mechanical properties of the developed samples were investigated according to the standard. The obtained results are presented in Table 1.

The air permeability of the plush knitted fabric of the lined interloping in comparison with the basic interloping is significantly lower among the samples of plush knitted fabric of the lined interlooping, the lowest air permeability has variant III.

The air permeability of this variant is 46.3 cm3/cm2 sec, 33.1% less compared to the basic interlooping. The change of dressing leads to a change in the physical and mechanical properties of the plush knitted fabric of the lined interlooping.

The abrasion test results of the knitted fabrics show that the abrasion resistance of the developed plush knitted fabrics of the lined interloping is greater than that of the basic interlooping. The abrasion resistance of these variants varies from 15000 to 36000 cycles. The highest abrasion resistance of the III variant of plush knitted lined interlooping is 36000 cycles, 45.5% more than the basic interlooping.

Table 1 - Indicators of physical and mechanical properties of plush knitted fabrics

|

и 1 |

Linear yarn density, (Tex) |

ио g |

е О б к! ио о к! |

Breaking load, N |

Breaking elongation, (%) |

Irreversi ble deformati on εn, (%) |

Reversibl e deformati on ε0, (%) |

Shrinkage (%) |

||||||

|

ч5 О л S £ |

е 43 3 £ |

ад |

45 £ Й |

£ 43 Й £ Й |

45 £ |

Й £ ад Й |

Й 45 £ £ ад Й |

Й Й |

Й 45 £ Й |

£ 43 Й О £ Й |

Й 45 £ ад Й |

|||

|

20х3 |

20х3 |

46,2 |

20000 |

302,67 |

97 |

8 |

89,2 |

1,8 |

4 |

8,2 |

6 |

1,2 |

1,2 |

|

|

I |

20х3 |

20х3 |

66,9 |

15000 |

294,5 |

20,8 |

6 |

113,1 |

2,6 |

3,5 |

7,4 |

6,5 |

1,4 |

2 |

|

II |

20х3 |

20х3 |

46,3 |

36000 |

317,4 |

08,5 |

4,3 |

97,4 |

3,2 |

5,3 |

6,8 |

4,7 |

2 |

1,3 |

|

V |

20х3 |

20х3 |

51,1 |

25000 |

299,7 |

03 |

9,75 |

97,43 |

9,5 |

2,6 |

0,5 |

7,4 |

1,2 |

1,8 |

The breaking load along the length of the plush knitted fabric of the lined interlooping varies from 294.5 to 317.4N. The strongest is the III variant of the plush knitted fabric, where the breaking load along the length is 317.4N, 4.9% higher than that of the basic interlooping .

The shrinkage along the length of the proposed plush knitted fouter interlooping varies from 11 to 12 %.

In conclusion, it should be noted that the recommended variants of samples of plush knitwear of fouter interlooping have improved indicators of technological parameters.

Comparing the volumetric density of the lined knitted fabric with elongated lined broaches with the basic lined knitted fabric, it can be seen that the presence of elongated broaches in the structure of the lined knitted fabric increases the thickness and decreases the volumetric density of the knitted fabric.

In addition, in the fourth variant, the formation of fouter drafts through the needle leads to a stronger fixation of the fouter thread in the knitted fabric ground, as a consequence of this improvement of form-stable, heat-protective, as well as consumer properties of the knitted fabric.

The obtained knitted fabric can be successfully used for the manufacture of outerwear and children's assortment.

The experiments were conducted according to the plan KONO-2 to study the influence of technological parameters on the bulk density of knitted fabric, breaking load (in length and width) and air permeability index [19].

The found coefficients of the regression equation are included in Table 2. The regression equation describing the dependence of technological parameters affecting the bulk density of knitted fabric, breaking load (length and width) and air permeability was created.

Table 2 - Coefficients of the regression equation

|

B0 |

B1 |

B2 |

B3 |

B4 |

B5 |

|

333,006 |

2,13 |

5,8 |

4,75 |

0,83 |

-4,17 |

|

42,42 |

-5,4 |

3,03 |

-0,77 |

3,13 |

9,6 |

|

305,56 |

4,27 |

0,29 |

1,15 |

-2,3 |

-3,75 |

|

198,4 |

3,62 |

2,15 |

-2,4 |

9,46 |

6,51 |

Y = 333,006+ 2,13*X 1 +5,8*X 2 + 4,75*X 1 *X 2 + 0,83*X 1 2 - 4,17*X 2 2

Y =42,42--5,4*Х 1 +3,03*Х 2 -0,77* Х 1 * Х 2 -3,13*Х 12 +9,6*Х 22

Y = 305,56+ 4,27*X 1 -0,29*X 2 + 1,15*X 1 *X 2 -2,3*X 1 2 -3,75*X 2 2

Y =198,4-3,62*Х 1 -2,15*Х 2 -2,4* Х 1 * Х2+9,46*Х 12 +6,51*Х 2

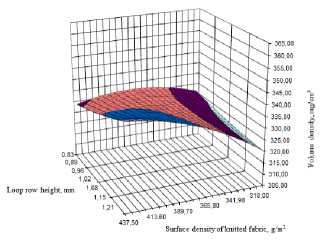

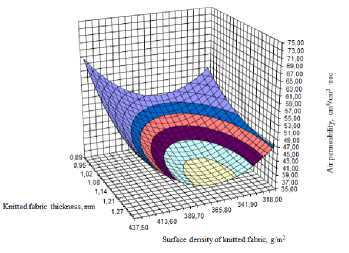

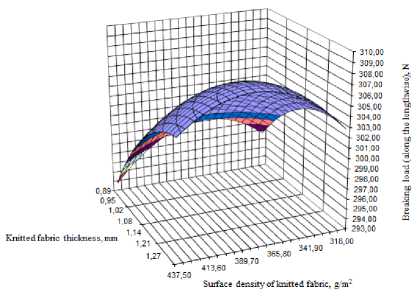

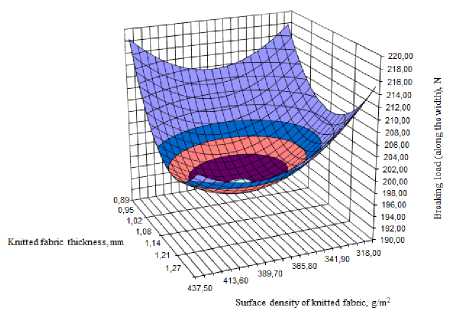

Figures 4-7 show a mathematical model of the dependence of technological parameters on the bulk density of knitted fabric, breaking load (length and width) and air permeability index.

Figure 4 - Dependence of knitted fabric bulk density on technological parameters

Figure 5 - Dependence of air permeability of knitted fabrics on technological parameters

Figure 6 - Dependence of breaking load of knitted fabric (by length) on technological parameters

Figure 7 - Dependence of breaking load of knitted fabric (width) on technological parameters

Conclusion

To obtain knitted fabrics with reduced material consumption due to the change of structure the possibility of using plush fouter knitted fabric was considered.

As a result of experimental work the technological capabilities of flat knitting machine КН – 323D were studied and new types of cotton knitted fabrics of fouter weave were produced. Comparing the volume density of the lined knitted fabric with elongated fouter broaches with the basic lined knitted fabric, it is possible to make sure that the presence of elongated broaches in the structure of the lined knitted fabric increases the thickness and decreases the volume density of the knitted fabric.

The air permeability of the plush knitted fabric of the lined weave compared to the basic weave is much less. It is found that the air permeability coefficients can be reduced to 33.1% (46.3-66.9 cm3/cm2∙sec) by adjusting the length of fouter broaches of combined plush cotton knitted fabric.

Regression equations were derived to determine the dependence of volume density, breaking load (length and width) and air permeability index of knitted fabric on technological factors. Mathematical models were built in Excel program using regression equations. The research results allow to improve the quality and consumer properties of knitted products, to choose advanced production technologies for their production.

Список литературы Research of physical and mechanical properties of knitted fabrics of plush interlooping with reduced material consumption

- Dal Forno, A.J., Bataglini, W.V., Steffens, F. And Ulson de Souza, A.A. (2023), "Industry 4.0 in textile and apparel sector: a systematic literature review", Research Journal of Textile and Apparel, Vol. 27 No. 1.- RR. 95-117

- Sarybayeva E.Ye., Kuramysova M.U., Mukimov M.M. "Opredeleniye sposobnosti nitey i pryazhi k pererabotke na vyazal'nykh mashinakh pri vyrabotke plyushevogo trikotazha [Determination of the ability of threads and yarn to be processed on knitting machines when producing plush knitwear] ", The Journal of Almaty Technological University, 2018 (2): 46-50 RR (Іn Russіan)

- Tsitovich I.G., Galushkina N.V. "Mezhdunarodnyye vystavki ITMA - dostizheniya v oblasti inzhenernoy mysli i esteticheskogo dizayna [International exhibitions ITMA - achievements in the field of engineering and aesthetic design] " Textile industry technology, 2016 (5(365)).-RR - 236-246 (Іn Russіan)

- Makhmudova G.I. Double-sided lined plush knitwear. Positive decision on patent No. 23514 of December 15, 2010.

- Zhang A. et al. 3D simulation model of warp-knitted patterned velvet fabric //International Journal of Clothing Science and Technology. - 2016. - T. 28. - №. 6. - RR. 794-804.

- Xiong Y. et al. Computer simulation for warp-knitted brushed fabric with patterned piles //Textile Research Journal. - 2016. - T. 86. - №. 15. - RR. 1659-1667.

- Mukimov M. M., Gulyayeva G. KH. "Tekhnologiya vyrabotki formoustoychivogo plyushevogo trikotazha [Technology for producing shape-resistant plush knitwear]" News of higher educational institutions. Light industry technology, 2017 (1) - .RR. 80-83 (Іn Russіan)

- Karatayev M.S., Salikh SH. Tashpulatov, U.S. Rakhmatullayeva, D. Yakh'yayeva, N. Abdurakhmanova, SH.P. Shumkarova i ZH. Abdurayev. "Analiz vliyaniya struktury osnovnogo perepleteniya na fiziko-mekhanicheskiye svoystva plyushevogo trikotazha [Analysis of the influence of the structure of the main weave on the physical and mechanical properties of plush knitwear] " News of higher educational institutions. Textile industry technologies, 2021 ( 4(394)) - RR.110-113 (Іn Russіan)

- Makhmudova, G. I.. “Research of influence of structure on properties plush jersey of children's clothing.” (2019).

- Skornyakov V. Ye. i dr. "Sposob vyazaniya kulirnogo trikotazha platirovannykh perepleteniy s plyushevym vorsom [Method of knitting knitwear with plated weaves and plush pile] " - News of higher educational institutions. Textile industry technology, 2017 (3), RR - 170-174 (Іn Russіan)

- Bykouskij D. I., Charkovsky A. V., Dyagilev A. S. Study of the Process of Hybrid Plush Knitwear Moistening //Fibre Chemistry. - 2023, RR. 1-4.

- Musayeva M. M., Khankhodzhayeva N. R., Mukimov M. M. "Razrabotka stroyeniya i sposoba polucheniya trikotazha iznanochnogo dvulastichnogo perepleteniya [Development of the structure and method of producing knitwear with purl bi-stretch weave] " - Mechanics and Technologies, 2014 (1),RR.- 76-80 (Іn Russіan)

- Ubaydullayeva D. KH., Akhmedova M. F. "Issledovaniye fiziko-mekhanicheskikh svoystv zhakkardovogo trikotazhnogo perepleteniya [Study of the physical and mechanical properties of jacquard knitted weave] " -Economy and Society, 2022 (10-1), RR.600-607 (Іn Russіan)

- Zhang A. et al. 3-D simulation of double-bar plush fabrics with Jacquard patterns //Autex Research Journal. - 2018. - T. 18. - №. 3. - RR. 243-250.

- Lei H., Cong H. L., Zhang A. J. CAD design and simulation of double-needle bar short pile fabrics [J] //Journal of Textile Research. - 2013. - T. 34. - №. 7. - RR. 132-136.

- Abd El-Hady R. A. M., Abd El-Baky R. A. A. The influence of pile weft knitted structures on the functional properties of winter outerwear fabrics //J. Am. Sci. - 2015. - T. 11. - №. 9. -RR.118-N.

- Kabbari M. et al. Predicting stain repellency characteristics of knitted fabrics using fuzzy modeling and surface response methodology //The Journal of The Textile Institute. - 2017. - T. 108. - №. 5. - RR. 683-691.

- Honglia, Cong. “Simulation of jacquard pile fabric based on texture synthesis.” Textile Research Journal (2014): n

- Sevost'janov A.G. "Metody i sredstva issledovanija mehaniko-tehnologicheskih processov tekstil'noj promyshlennosti [Methods and means of studying the mechanical and technological processes of the textile industry.] " Moskva: MGTU A.N. Kosygina, 2007.- 648 R (In Russian)