Safety research of textile materials with flame retardant properties

Автор: Baimakhanova M.B., Jurinskaya I.M., Taussarova B.R.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 3 (145), 2024 года.

Бесплатный доступ

This article discusses the findings of a study that explored the use of new compositions containing tetraethoxysilane, sodium dihydrogen phosphate, and hexamethylenediamine to improve the flame retardancy of cellulose fiber materials. The impact of different components and temperatures on the fire-resistant properties of the fabric was examined. In an untreated sample measuring 17*22 cm, ignition occurred in 15 seconds and the fabric burned completely within 60 seconds, whereas a treated sample showed signs of retardation. Increasing the concentration of flame retardant impregnation at a temperature of 150 degrees had minimal effects on the material's strength, air permeability, and appearance. With the help of electron scanning device it was found that on the surface of the fibers of the treated sample morphological changes were observed in the form of film, which in turn contain particles of Si (25.48%), P (17.61%), Na (1.70%). The optimum conditions of fabric processing are determined, the influence of concentration of working solution, impregnation and thermofixation temperature on flame retardant properties of fabrics investigated, also processing can be carried out on standard equipment of finishing enterprises and laboratories. Cotton materials treated with a compound based on tetraethoxysilane, sodium dihydrophosphate and hexamethylenediamine provides adequate fire resistance.

Cotton materials, flame retardant properties, fire-resistant effect, tetraethoxysilane, hexamethyldiamine, sodium dihydride phosphate

Короткий адрес: https://sciup.org/140306352

IDR: 140306352 | DOI: 10.48184/2304-568X-2024-3-177-183

Текст научной статьи Safety research of textile materials with flame retardant properties

МРНТИ 64 29 81

In today's world, safety is one of the most important factors in the production and use of textile materials. Flame retardant treatments and technologies applied during textile manufacturing have become crucial tools in ensuring safety.

Research into the safety of textile materials with flame retardant properties is of great importance, as the proper selection and application of such materials can save lives in the event of fire or other emergencies. Giving flame retardant and antimicrobial properties to materials can play a major, positive role in the home. The use of this kind of textile materials is beneficial and safe for society. According to the results of scientific articles, the authors note that the use of textile with complex properties solves a number of problems, such as environmental and economic aspects.

The challenge of bestowing flame-retardant properties to textiles of various compositions and uses is becoming increasingly significant. This importance stems from the fact that textile materials pose a serious fire hazard due to their high flammability, their role in flame propagation, and their tendency to produce large amounts of smoke and toxic gases when burned. Statistics reveal that a significant portion of fires, over 38%, occur in residential and public buildings, with residential structures alone accounting for over 70% of these incidents.

With the expansion of polymeric material (PM) production and their widespread application across construction, industry, and transportation, the focus on developing materials with reduced fire hazards and predefined fire-resistance properties has become a priority. Textiles are used in numerous applications, including domestic, industrial, transportation, and specialized protective equipment. Cel-lulose-containing fabrics have excellent properties, due to these properties are of interest to others, for example, they have the ability to renew raw materials, also environmental important aspect as recycling of production waste, as well as thermal, hygienic physico-chemical, also mechanical. Moreover, natural fibers, polymers, and bio-based fillers are completely biodegradable.

Researchers have recently turned their attention to fire-retardant natural fibers and bio-based composite materials. Polymers like polyurethane foam and fiber fabrics are notably flammable and produce significant amounts of droplets that can escalate fire spread rapidly. Thus, there is a critical need for high-performance flame retardants or flame-retardant technologies to ensure the safety and reliability of polymer-based composites. Environmentally friendly, layer-by-layer flame retardant coatings are particularly promising as they enhance the flame-retardant properties of polymers without altering their intrinsic characteristics.

Cellulosic fabrics are not only affordable but also possess numerous beneficial properties, making them a popular subject of study among researchers. This raw material is derived from renewable plant sources, highlighting its sustainability.

Efforts to improve the flame retardancy of textiles have been ongoing for decades, focusing on incorporating flame retardants into fiber matrices or modifying the surfaces of textiles directly. A variety of flame retardants, including inorganic and organic types, are utilized to impart effective flame resistance to textiles. Common inorganic flame retardants contain elements such as phosphorus, bromine, iron, and carbon. Frequently used organic flame retardants include those that are halogenated or contain phosphorus, nitrogen, or silicone.

In summary, enhancing the flame-retardant properties of textiles is a critical area of research due to their widespread use and inherent fire hazards. Advances in environmentally friendly flame retardant technologies are paving the way for safer, more reliable textile applications. [9].

Currently, global standards encompass regulations that define the fire hazard metrics for textile materials. These metrics are influenced by various factors, including the chemical structure of the materials, product geometry, environmental conditions, ignition sources, and exposure duration. As a result, over 100 laboratory methods (national, ISO, EN, IMO, etc.) are employed worldwide to determine the combustion and ignition characteristics of textiles.

There has been notable progress in developing textile materials with flame-retardant properties. According to statistical data, efforts to impart flame retardant attributes to textiles have achieved considerable success. However, the need for enhanced fire-retardant solutions persists as the industrialization of novel flame retardants is a complex task, requiring factors such as high efficacy, low smoke emission, minimal toxicity, biocompatibility, cost-efficiency, and wash durability.

Nearly all textile materials are flammable and can ignite when exposed to low-power ignition sources, with flames readily spreading across their surfaces. Consequently, fires in indoor environments often commence with the ignition of textile products. Additionally, the combustion of textile materials releases hazardous chemicals and smoke, which significantly hampers evacuation efforts and poses a substantial risk during fires.

To mitigate fire risks effectively, it is more advantageous to use textiles with built-in flameretardant properties. Such materials are suitable for various applications, including furniture upholstery, wall coverings, curtains, carpets, and other home interiors. Utilizing these flameretardant textiles can slow the spread of fire, providing crucial extra minutes for evacuation or fire suppression.

Research by Swiss scientists indicates that incorporating chemical elements such as halogens (P, Br, S, N) and metals into the composition of non-flame-retardant fabrics can render them fireresistant. The goal of ongoing research is to develop textiles with inherent flame-retardant properties. The proposed approach involves using tetraethoxysilane as the primary reagent for component preparation, acetic acid as a hydrolysis catalyst, and other chemical substances capable of reducing textile flammability.

This ensures that textiles with flameretardant properties can significantly improve fire safety by delaying combustion and providing crucial intervention time during fire incidents.

Materials and research methods

The research focuses on bleached, unfinished cotton fabric, specifically article 1030. This cotton fabric has the following structural characteristics: a width of 220 cm, a plain weave pattern, and a composition of 100% cotton. The study also examines chemical substances designed to reduce fabric flammability and minimize the formation of toxic combustion byproducts.

Tetraethoxysilane ((C2H5O)4Si) is a simple ester derived from orthosilicic acid and ethyl alcohol. It appears as a volatile, transparent, colorless liquid with a distinctive spicy-sweet, somewhat alcohol-like odor. Sodium dihydrogen phosphate (NaH2PO4) is an inorganic compound that forms colorless crystals, easily soluble in water, and can create crystalline hydrates. Hexamethylenediamine, with the formula NH2(CH2)6NH2, resembles piperidine and is characterized by colorless crystals with an amine odor. It is readily soluble in organic solvents.

The procedure for treating the cotton fabric with a sol-gel composition involved immersing cotton samples in a bath containing tetraethoxysilane (98.5%), acetic acid (99.7%), and sodium hydrogen phosphate. This was followed by the application of hexamethylenediamine solutions for 7 minutes, after which the samples were wrung to 90% humidity. The fabric samples were then dried at 80-85°C for 6 minutes and subsequently heat-treated at 140°C and 150°C for 3 minutes. Finally, the fabric was washed thoroughly with distilled water and dried at room temperature.

Flammability and combustion resistance of fabric and nonwoven materials were tested according to GOST R 50810-95. This standard includes combustible decorative and textile materials, which are also intended for ordinary consumption in everyday life.

Tensile strength tests of the fabric samples were conducted using the RT-250M-2 tensile machine, which moves the lower clamp uniformly at a speed of 250 mm per minute, following GOST 8847-85 guidelines. An electron-microscopic study was conducted using a JEOL JSM-6510LA scanning electron microscope (SEM) manufactured by JEOL (Japan). Air permeability measurements were performed using an MT 160 device, in accordance with GOST 12088-77.

By following these methods, the study aims to enhance the flame retardant properties of the cotton fabric while maintaining its structural and functional integrity.

Results and discussion

Research indicates that untreated fabric ignites within 15 seconds and is completely consumed by flames in 60 seconds. In contrast, samples treated with a flame retardant exhibit delayed ignition.

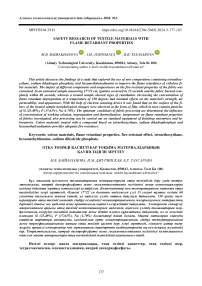

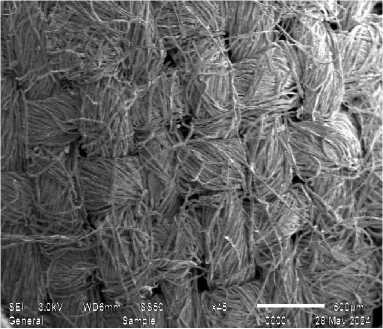

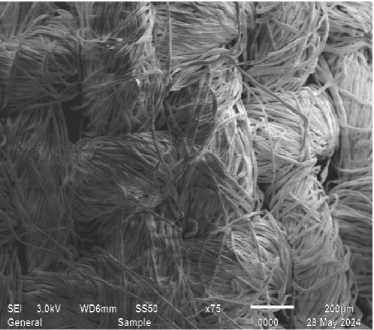

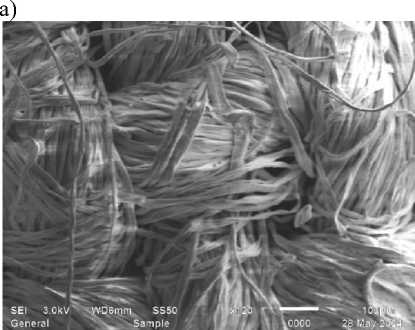

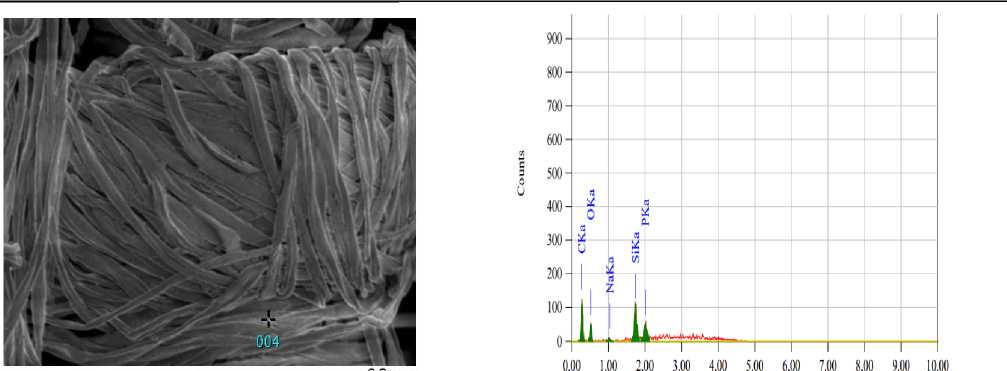

On the surface of fibers of the treated sample in comparison with untreated fabric morphological changes are observed - a transparent film, as evidenced by electron microscopic images (Fig.1). According to the images it can be observed that the untreated material (cotton fabric) shows 67.8 % carbon and 29 % oxygen. However, treated fabric surfaces contain additional particles, specifically Si (25.48%), P (17.61%), and Na (1.70%).

As the concentration of the flame retardant in the modifying composition increases, the phosphorus content in treated samples also rises to 17.61%.

resolution .

b)

c)

Figure 1. Electron-microscopic images of the surface of the fabric treated with flame retardandt composition of different

a) b)

Figure 2. Electron microscopic images of fabric modified with flame retardant composition (a), energy dispersive microanalysis (b)

Table 1. Results of energy dispersive analysis of samples modified with fire retardant impregnation

|

№ |

Flame -retardant, gl |

Weigl |

it fraction, % |

Atomic fraction, % |

|||

|

C |

О |

Na 1 Si 1 P |

C |

О |

Na 1 Si 1 P |

||

|

1 |

Original sample |

67,8 |

29 |

72.6 |

25,8 |

||

|

2 |

Na H;PO4 |

42,71 |

13,49 |

1,70 1 25,48 1 17,61 |

60,22 |

14,28 |

1,51 1 15,26 1 9,63 |

Tensile strength tests revealed that the untreated fabric has a breaking load of 294.3 N. Post-treatment at 150°C, this value marginally increases to 303.1 N (Table 2). Although the appearance of the fabric remains largely unchanged with higher concentrations of flame retardant treatments, there is a slight reduction in fabric strength.

The study confirms that the investigated modifying components, when applied in specific dosages, significantly enhance the fabric's flame retardancy. The air permeability for untreated cotton fabric is recorded at 188.6 dm3/m2s, while it slightly decreases to 183.5 dm3/m2s for the treated fabric. These values remain within the hygienic safety standards for such materials. (Table 2).

Table 2. Test results of samples impregnated with fire retardant composition

|

Concentration of substances, g l |

Air permeability, dm3/m2s |

Length of charred area, mm |

Breaking load, N |

||||||

|

Original sample |

|||||||||

|

Head treatment temperature,0 C |

|||||||||

|

188 |

,6 |

220 |

294,3 |

||||||

|

1 |

CiHjOJjSi |

Na НзРОі |

NHrCCHjJtNHr) |

140 |

150 |

140 |

150 |

140 |

150 |

|

2 |

20 |

120 |

50 |

133,5 |

181 |

125 |

115 |

302,7 |

303,1 |

The formation of a thin polymer film on the fibers of cotton fabric can significantly enhance its properties, including strength, moisture resistance, and heat tolerance. Alterations in the morphology of treated samples suggest potential changes in their physicochemical characteristics, which could be advantageous for various applications.

Evaluating the elemental content before and after modification of the cotton fabric provides insights into the effectiveness of the treatment process and the impact of added components on the material's composition and structure. The presence of Si, P, and Na particles on the treated fabric surface indicates interactions between the modifier and the fabric, potentially leading to the formation of new compounds that may alter the material's properties.

Conclusion

A novel flame retardant composition, comprising tetraethoxysilane, sodium dihydrophos- phate, and hexamethylenediamine, has been developed specifically for cellulose materials. Notably, sodium dihydrophosphate significantly enhances the flame-retardant properties when combined with hexamethylenediamine, achieving the desired protective effect.

This composition changes morphologically the surface of the fibers, as evidenced by electron microspot images. The work also took into account the parameters of work concentration, impregnation process, temperature, thermofexation, which had an influence on the imparting of flame retardant properties to the material. It is also important to consider that this experiment can be carried out in ordinary laboratories using standard equipment.

This newly proposed composition offers superior fire resistance performance for cellulose-based textiles.

Список литературы Safety research of textile materials with flame retardant properties

- Таусарова Б.Р., Стасенко Ю. Придание огнезащитных свойств целлюлозным текстильным материалам с применением золь - гель технологии. Химия растительного сырья, № 4, 2019: 365-372 https://doi.org/10.14258/jcprm.2019044286

- Таусарова Б.Р., Такей Е. Золь-гель технология придания огнезащитных свойств целлюлозным текстильным материалам. Наноидустрия, №1, 2018: 68-72 https://doi.org/10.22184/1993-8578.2018.80.1.68.73

- Константинов Н.И., Зубань А.В., Булгакова A.A. Совершенствование методологического подхода к оценке пожарной опасности матрацев. Безопасность веществ и материалов, № 31 (2), 2022: 22-32 https://doi.org/10.22227/0869-7493.2022.31.02.22-32

- Konstantinov N.I., Smirnov N.V., Shebekov A.Yu. Revisiting the assessment of polymeric materials fire protection efficiency. Safety of substances and materials, Volume 27, №7-8, 2018: 37- 42 https://doi.org/10.18322/PVB.2018.27.07-08.32-42

- Смирнов Н.В. Комплексная оценка пожарной опасности текстильных и кожевенных материалов: рекомендации. Всероссийский научно-исследовательский институт противопожарной защиты, 2014: 28

- Спиридонова В.Г., Сорокин Д.В., Никифиров В.Г. Циркина О.Г. Обоснование актуальных подходов к оценке пожароопасных свойств текстильных материалов и способов огнезащиты тканей различного функционального назначения. Cо-временные проблемы гражданской защиты, № 2 (47) 2023:125-132.

- Shah A.U.R., Prabhakar M.N., Song J. Cur-rent Advances in the Fire Retardancy of Natural Fiber and Bio-Based Composites – A Review. International journal of precision engineering and manufacturing-green technology, 2017: 242–262 https://doi.org/10.1007/s40684-017-0030-1

- X. Qiu., Zh. Li., Zh. Zhang Flame retardant coatings prepared using layer by layer assembly. Chemical Engineering Journal, №334, 2018:108-122 https://doi.org/10.1016/j.cej.2017.09.194

- Jin L., Ch. Ji., Sh. Chen Multifunctional Tex-tiles with Flame Retardant and Antibacterial Properties. Molecules, no 28 (18), 14 September 2023:19-22 https://doi.org/10.3390/molecules28186628.

- Малых А. Р. Ассортимент современных огнестойких текстильных материалов. Научно-методический электронный журнал «Концепт», Т. 3, 2016:116–120 http://e-koncept.ru/2016/56035.htm

- Таусарова Б.Р., Кутжанова А., Абдрахма-нова Г. Снижение горючести текстильных материа-лов: достижения и перспективы. Химический жур-нал Казахстана, №1 2015:287–303

- Таусарова Б.Р., Канлыбаева Г.С., Бирим-жанова З.С. Применнеие полиэтиленполиамина и гидрофосфат калия для придания огнезащитных свойств целлюлозным текстильным материалам. Химический журнал Казахстана, № 2. 2016:201–207 ISSN 1813-1107

- Ozer M. S., Gaan S. Recent developments in phosphorus based flame retardant coatings for textiles: Synthesis, applications and performance, Science Di-rect: Progress in Organic Coatings, Volume 171, Oc-tober 2022 https://doi.org/10.1016/j.porgcoat.2022.107027

- Сторонкина О.Е., Мочалова Т.А., Калаш-ников Д.В., Исследование показателей пожарной опасности текстильных материалов в целях судеб-ной пожарно-технической экспертизы. Современ-ные наукоёмкие технологии. Региональное прило-жение. №4 (68) 2021, С. 80-85 http://e-koncept.ru/2014/14891.htm.

- Attia F.N.,Morsy M.S. Facile synthesis of novel nanocomposite as antibacterial and flame retard-ant material for textile fabric, Materials chemistry and physics, Volume 180, September 2016: 364-372 https://doi.org/10.1016/j.nanoso.2024.101180

- Attia F.N., Elashery E.A., El-Sayed F. Re-cent advances in nanobased flame – retardant coating for textile fabrics, Nano-Structure and Nano Objects, Volume 38, May 2024 https://doi.org/10.1016/j.nanoso.2024.101180

- Salmeia K., Gaan S., Malucelli G. Recent advances for flame retardancy of textiles based on phosphorus chemistry, Polymers, Volume 8, 2016: 1–36 https://doi.org/10.3390/polym8090319