The efficiency of using new brands silica gel for colloidal stabilization of beer

Автор: Razan H., Meledina T.V., Chernikhovec E.A., Manshin D.V.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевая биотехнология

Статья в выпуске: 4 (90), 2021 года.

Бесплатный доступ

The production of beer that meets the requirements of consumers in terms of quality and price is one of the most important aspects of competition in their sales market. It is known that the quality of the beer is associated with colloidal stability, which is often achieved through the use of different methods, such as chemical, enzymatic and physicochemical methods. Chemical methods are used to reduce the rate of oxidative processes in beer by introducing antioxidants. At the same time, enzymatic methods are often used in the mashing step. They involve enzyme preparations to regulate the levels of protein and carbohydrates (?-glucans and dextrins) in the beer. In breweries, physicochemical methods based on adsorbents that help remove major haze components such as protein and polyphenols from beer are commonly used. Since expensive imported materials such as silica gel and PVPP are widely used in Russia, which leads to additional production costs, this work is devoted to studying the possibility of reducing the costs of beer stabilization by replacing imported silica gels with domestic ones. For the study, we used domestic silica gels manufactured by "Tovesorb" (Russia). In addition, we used silica gels of foreign production Stabifix (Germany) and Britesorb L10 (Netherlands) as a control. The obtained results showed the prospects of using domestic brands of silica gel from "Tovesorb" (Russia), which were not inferior to imported analogues in terms of their adsorption properties.

Beer haze, colloidal stability, silica gel, alternative stabilizer

Короткий адрес: https://sciup.org/140290644

IDR: 140290644 | УДК: 663.4 | DOI: 10.20914/2310-1202-2021-4-169-174

Текст научной статьи The efficiency of using new brands silica gel for colloidal stabilization of beer

Currently, brewing is one of the essential industries that are steadily developing in Russia. This development was associated with a constant striving to increase the quality of the final product, significantly improving its organoleptic properties and colloidal stability. However, the preservation of beer properties for an extended time is affected Для цитирования

by several factors, including the quality indicators of barley and yeast the technological processes during the different production stages [1].

Various methods, including enzymatic and technical, are widely used in the industry to increase the shelf life of beer. The enzyme preparations are used at the mashing stage to regulate the level of proteins and carbohydrates (β-glucans

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International License and dextrins), whereas technological methods based on the regulation of physical and chemical conditions of the environment aim to reduce the rate of oxidative processes and remove haze-forming colloids during the beer filtration process, which is the most critical stage affecting the colloidal stability of beer during the production process [2]. Proteins, polyphenols and polysaccharides are known to be the main compounds that cause beer haze. The increase in polysaccharide content in beer is mainly attributed to incorrect mashing process and improper handling of yeast. Thus, the use of inoculum with low physiological activity and untimely removal of yeast leads to autolysis of cells and an increase in glycogen content in beer [3]. Thus, the use of inoculum with low physiological activity and untimely removal of yeast leads to autolysis of cells and an increase in glycogen content in beer [3]. On the other hand, the mashing process requires constant adjustment due to constantly changing quality indicators of malt and unmalted materials.

The amount of polyphenols in the product is affected by the quality of the raw materials, filtering the mash, and removing yeast from beer [4, 5]. Currently, in the Russian Federation, an imported Polyvinylpolypyrrolidine (PVPP) is often used to remove haze-forming phenolic compounds from beer [6], and some large companies, which use expensive equipment for PVPP regeneration are limited to this procedure [7]. In this regard, some Russian researchers have proposed hexamine derivatives [8] and substances of natural origin, such as chitosan and modified starch [9], as absorbent materials for polyphenols to increase the colloidal stability of drinks.

However, due to the lack of alternative materials for PVPP, most breweries still use silica gel to remove haze-forming proteins from beer. The recommended dosage of silica gel is 30–50 g/m2 filter's area. At the same time, the contact time of the beer with the stabilizer depends on the temperature of the beer, where at a temperature of -1℃ for the maximum effect, 4–5 minutes is enough, while at + 1℃ it is required to hold a beer with silica gel for 7–8 minutes [1].

Due to the rising costs of auxiliary materials and the slowdown in logistics supplies from abroad, it became necessary to use domestic brands of silica gel during the production of beer. In this context, the only manufacturer of silica gel for colloidal stabilization of beer currently in the Russian Federation is "Tovesorb", which offers brands of the ВriS series (ВriS 10, ВriS 40 and ВriS 60).

Materials and methods

Research objects were domestic silica gels Bris 60 and Bris 10 (ООО «Товесорб», Russia). In addition, foreign-made silica gels Stabifix (Germany) and Britesorb L10 (Netherlands) were used as a control.

Table 1 shows the essential parameters of silica gel in terms of beer stabilization compared to imported analogues. The samples of the Bris 60 (Russia) and Stabifix (Germany) brands (dry matter content of > 35.0%) are referred to as hydrogels. In contrast, samples Bris 10 (Russia) and Britesorb L10 (Netherlands) are referred to as xerogels (dry matter content ≥ 88.60%).

The samples of unfiltered beer produced at the breweries of St. Petersburg were used during this work. The indicators of beer samples are shown in table 2.

Таблица 1.

Физико-химические характеристики гидрогелей и ксерогелей по данным производителя

Table 1.

Physicochemical characteristics of hydrogels and xerogels according to the manufacturer's data

|

Parameters |

Brands of Silica gel |

|||

|

Hydrogel Bris 60 |

Stabifix |

Xerogel Вris10 |

Britesorb L10 |

|

|

№ sample |

1 |

2 |

3 4 5 |

6 |

|

W, % |

58,90 |

36,32 |

11,40 6,03 7,0 |

6,20 |

|

Dry matter, % |

41,10 |

63,68 |

88,60 93,97 93,0 |

93,80 |

|

рН (5% water solution) |

3,5–5,5 |

4,0 |

6,0–8,0 |

– |

|

Size of particles D50, μm (ASTM С1070–01) |

17,0–21,0 |

17,3 |

12,0–14,0 |

– |

|

Content SiО2, % |

96,0 |

96,0 |

96,0 |

– |

|

Specific surface area, m 2 /g |

600–950 |

740 |

400–600 |

– |

|

Pore volume, сm 3 /g |

0,7–0,85 |

0,61 |

0,8–1,1 |

– |

|

Pore diameter, nm |

3,3–4,0 |

3,32 |

8,0–11,0 |

– |

Примечание: (–) нет информации

Note: (–) no information

Таблица 2.

Физико-химические показатели образцов исследуемого пива

Table 2.

Physicochemical indicators of the samples of the studied beer

|

Indicators |

Beer samples |

||

|

1 |

2 |

3 |

|

|

Ethanol, % v |

5,25 |

4,06 |

8.43 |

|

Ethanol, m% |

4,12 |

3,15 |

6,58 |

|

Ea, % (m/m) |

1,896 |

3,15 |

2.764 |

|

Er, % (m/m) |

3,799 |

3,962 |

5,673 |

|

Dry matter (DM), % |

11,79 |

12,1 |

18.03 |

|

RDF, % |

69,18 |

69,45 |

70,58 |

|

ADF, % |

83,92 |

80,90 |

84.66 |

|

Concentration of yeast cells, cfu mL -3 |

0,5 |

1,5 |

0,05 |

To study the adsorption properties of silica gels, two series of experiments were carried out. In the first series of experiments, two samples of beer 1 and 2 were used. The filtration process was carried out using a laboratory installation (Figure 1).

Before beer filtering, filter plates were washed with a citric acid solution (2%), and then diatomaceous earth was added over the filter (30 g/hL beer). After that, the diatomaceous earth was washed with distilled water. In all variants of the experiments, the dosage of silica gel was 30 g (absolute dry matter)/100 l beer. The dosages were calculated, taking into account the conversion to dry matter, which was 65%. The amount of filtered beer was 250 ml. The beer was held with silica gel for 10 min, and then was filtrated using the laboratory installation.

Рисунок 1. Лабораторная установка для фильтрации

Figure 1. Laboratory installation for filtration

Silica gel Stabifix (sample № 2) was used as a control. Since all silica gel samples had different moisture content, the stabilizer was calculated, taking into account the content of dry matter (Table 3).

Таблица 3.

Фактический расход силикагеля, использованного для обработки пива

Table 3.

Actual consumption of silica gel, used for beer processing

|

Parameter |

Brands of silica gel |

|||

|

Hydrogel Bris 60 |

Stabifix |

Xerogel Вris10 |

||

|

1 |

2 |

4 |

5 |

|

|

Silica gel consumption, g/hL of beer |

47,44 |

30,62 |

20,75 |

20,96 |

In the second series of experiments, the effectiveness of the silica gel Вris10 (sample № 3) was evaluated at a brewery. As a control, the silica gel Britesorb L10 (sample №. 6) was used.

Since this study was carried out using strong beer (beer № 3 with initial content of dry matter 18%), the dosage of silica gel was increased to 40 g / hL beer. Conversion to absolute dry matter was not carried out. Filtration was carried out on a Filtrox candle filter. After filtration, the turbidity and chill haze stability of beer were evaluated.

Physicochemical indicators of beer were determined using an Alcolyzer plus beer analyzer (Anton Paar, Austria).

The determination of beer turbidity was carried out using a turbidity meter (Haffmans Vos Rota 90/25, Netherland) and the nephelometer (lohand biological, China) according to the instructions for determining the total haze of beer (Total Haze) MVI 56–05–02 “Measurement procedure. Beer. Determination of turbidity.” [10].

The chill haze stability of beer was assessed using the test "limit of protein precipitation by ammonium sulfate". This indicator is expressed by the amount of a saturated solution of ammonium sulfate (ammonium sulfate, cm³) before the appearance of turbidity in beer [10].

A forced test was carried out to determine the colloidal stability of beer at alternating temperatures of 60 ℃ and 0 ℃ (60/0). At each of these temperatures, the beer was thermostated for 24 h.

Zeta potential was determined on a device (Photocor Compact-Z," Photocor "LLC, Russia). For measurements, a suspension of an adsorbent with a concentration of 5% and рН = 7 was prepared. Adjustment of the рН value of the suspensions was by using the solution of phosphoric acid 8.6%.

The particle size of silica gel was estimated using an information-measuring system (IMS) based on the "GIU-1."

Results and discussion

Table 4 shows the turbidity values for beer 1 before and after processing. During separation, 75% of particles larger than 1 micron (Н25 index) were removed. At the same time, the amount of particles that subsequently affect the colloidal stability of beer (Н90) decreased by only 43%. In this case, the best effect was achieved when using prototype № 5.

Таблица 4.

Мутность пива 1 до и после обработки силикагелем

Table 4.

Beer turbidity 1 before and after treatment with silica gel

|

Parameter |

Beer after separation |

Beer after treatment with silica gel |

|

|

Xerogel Bris 10 № 5 |

Stabifix № 2 |

||

|

Turbidity, EBC (Н 90/Н25) |

11,3/4,99 |

0,37/0,25 |

0,52/0,61 |

Further experiments were carried out to compare the adsorption capacity of silica gels Bris 10 (samples 4 and 5) and Bris 60 (sample 1). The results presented in Table 5 show that all beer samples (2) treated with silica gel had low turbidity and high sedimentation limit of protein (26 ± 1 ml), indicating that the beer can be stored for three months.

Таблица 5.

Показатели, характеризующие коллоидную стабильность пива 2, обработанного силикагелем разных марок

Table 5. Indicators characterizing the colloidal stability of beer 2, which treated by different brands of silica gel

|

Раrаmеtеrs |

Beer after separation |

Beer after treatment with silica gel |

|||

|

Bris 60 |

Bris 10 |

Stabifix |

|||

|

1 |

4 |

5 |

2 |

||

|

Turbidity, NTU (λ = 560нм) |

0,837 |

0,148 |

0,154 |

0,137 |

0,133 |

|

Ammonium sulfate, ml |

– |

26 |

25 |

27 |

26 |

Таблица 6.

Мутность пива № 2 при искусственной выдержке

Table 6.

Turbidity of beer № 2 during artificial aging

|

Number of cycles 60/0 |

Brands of silica gel |

|||

|

Bris 60 |

Bris 10 |

Stabifix |

||

|

1 |

4 |

5 |

2 |

|

|

1 |

1,47 |

1,56 |

1,49 |

1,47 |

|

2 |

1, 87 |

1, 80 |

1,79 |

1,80 |

|

3 |

2,37 |

2,41 |

2,29 |

2,49 |

Thus, according to the results of laboratory studies, the prospects of using domestic brands of silica gel Bris 60 and Bris 10 in brewing have been confirmed.

The adsorption capacity of silica gel Bris 10 (sample № 3) was studied at a large-scale brewery.

Strong beer (18% DM) was treated with Bris 10 silica gel; at the same time, Britesorb L10 silica gel (Netherlands) was used as a control. During this study, the particle size and zeta potential of both silica gel samples were determined. The results are presented in Table 7.

Таблица 7. Физико-химические характеристики силикагелей Bris 10 и Britesorb L10

Table 7.

Physicochemical characteristics of silica gels Bris 10 and Britesorb L10

|

Parameters |

Brands of silica gel |

|

|

Bris 10 |

Britesorb L10 |

|

|

zeta potential, mV |

-14.27 |

-15,22 |

|

The particle size, μm |

7,05 |

7,69 |

The obtained results showed that the surfaces of the silica gel samples have a negative charge and almost the same zeta potential. In addition, the particle size meets the requirements for beer stabilization, which are in the range of 5–20 μm.

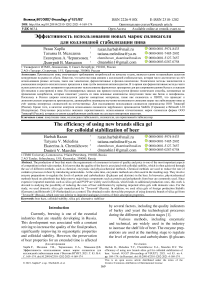

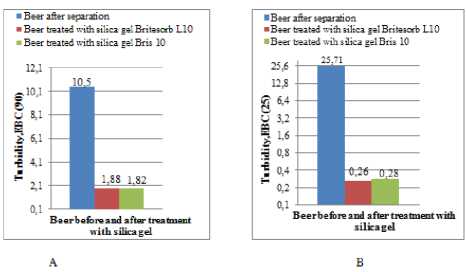

Indicators characterizing the turbidity of strong beer before and after processing are shown in Figure 2.

To confirm this conclusion, beer stabilized with silica gel was subjected to artificial ageing (forced test to determine the colloidal stability of beer). The test was carried out at alternating temperatures of 60 ℃ and 0 ℃ (60/0). At each of these temperatures, the beer was thermostated for 24 h.

The turbidity of the beer is measured after each cooling operation. Measurements are continued until the turbidity value reaches 2 units EBC. Thus, one day of beer ageing at 60° C (where the beer turbidity is less than 2 EBC) corresponds to one month of beer storage without the appearance of haze [10].

The results obtained from the forced ageing of beer (Table 6) confirmed that the beer could be stored for no less than three months.

Рисунок 2. Мутность пива № 3 до и после обработки силикагелем (A – Н90, B – Н25)

Figure 2. Turbidity of beer № 3 before and after treatment with silica gel (A – Н90, B – Н25)

The results show that the domestic sample of silica gel Brice 10 is not inferior to its foreign counterparts in terms of the efficiency of protein removal. In addition, it should be noted that the sedimentation limit which was used to assess protein turbidity after treatment of beer with silica gels of both brands was 26 сm3 (NН 4 ) 2 SО 4 /100 ml of beer; therefore, after stabilization, the beverage should have a stability of at least 6 months [1]. Thus, no statistical difference was found in beer quality when treated with domestic or foreign silica gel.

Conclusion

According to the obtained results, it was established that the samples of silica gel Bris 10 and

60 produced by "Tovesorb" (Russia) meet the requirements of the materials used for beer filtration.

The results obtained in the laboratory showed that the use of silica gel in the amount of 30 g / hl allows the beer to be stored for at least three months and provides selective adsorption of proteins at the level of 0.4–0.6 EBC. Furthermore, based on industrial tests at a large brewery, the effectiveness of using domestic brands of silica gel of the company "Tovesorb" (Russia) was proved, which in their adsorption properties were not inferior to the imported analogues of beer silica gels, such as Stabifix and Britesorb L10.

Список литературы The efficiency of using new brands silica gel for colloidal stabilization of beer

- Meledina T.V., Dedegkaev A.T., Afonin D.V. Beer quality. Colloidal and taste stability. St. Petersburg, Iz-vo Professiya, 2011. 220 p. (in Russian).

- Mastanjevic K., Krstanovi V., Lukinac J., Jukic M. et al. Beer-the importance of colloidal stability (non-biological haze). Fermentation. 2018. vol. 4. pp. 1-12. doi: 10.3390/fermentation4040091

- Wang J., Zheng L.M., Niu F., Liu C., Li C., Sun Q. Cell wall polysaccharides: before and after autolysis of brewer's yeast. World Journal of Microbiology and Biotechnology. 2018. vol. 34. pp. 1-8. doi: 10.1007/s11274-018-2508-6

- Kerr E.D., Coboche C.H., Schulz B.L. Post-translational modifications drive protein stability to control the dynamic beer brewing proteome. Mol Cell Proteomics. 2018. vol. 34. pp. 1721-1731. doi: 10.1074/mcp. RA119.001526

- Harbah R.A., Meledina T.V, Morozov A.A. The effect of yeast growth stages on the absorption of polyphenols. Agron Res. 2020. vol.18. pp. 1673-1679. doi: 10.15159/ar.20.053

- Kotlikova B., Jelinek L., Karabin M., Dostalek P. Precursors and Formation of Colloidal Haze in Beer. Chem List. 2013. vol.107. pp. 362-368.

- Zeller A.B. Kreuznach B. More economical stabilization of beer by means of regenerated PVPP. World of beer. 2019. no. 3. pp. 101-103. (in Russian).

- Mozharova Ya.R., Beteva E.A. Methods for improving the colloidal stability and persistence of the taste of beer. Colloquium-journal. 2019. no. 6-2. pp. 37-38. (in Russian).

- Afonin D.V. Influence of the processes occurring during the fermentation of wort on the initial turbidity of beer. Beer and drinks. 2012. no. 1. (in Russian).

- Ermolaeva G.A. Reference book for a brewery laboratory worker. St. Petersburg, Professiya Publishing House, 2004. 535 p. (in Russian).

- Mastanjevic K., Krstanovic V., Lukinac J., Jukic M. et al. Beer-the importance of colloidal stability (non-biological haze). Fermentation. 2018. vol. 4. no. 4. pp. 91. doi: 10.3390/fermentation4040091

- Buiatti S., Bertoli S., Passaghe P. Influence of gluten-free adjuncts on beer colloidal stability. European Food Research and Technology. 2018. vol. 244. no. 5. pp. 903-912. doi: 10.1007/s00217-017-3010-3

- Cimini A., Moresi M. Combined enzymatic and crossflow microfiltration process to assure the colloidal stability of beer. LWT. 2018. vol. 90. pp. 132-137. doi: 10.1016/j.lwt.2017.12.008

- Mikyska A., Dusek M., Slaby M. How does fermentation, filtration and stabilization of beer affect polyphenols with health benefits. Kvasny prumysl. 2019. vol. 65. no. 4. pp. 120-126. doi: 10.18832/kp2019.65.120

- Devolli A., Dara F., Stafasani M., Shahinasi E. et al. The influence of protein content on beer quality and colloidal stability. International Journal of Innovative Approaches in Agricultural Research. 2018. vol. 2. no. 4. pp. 391-407. doi: 10.29329/ijiaar.2018.174.12

- Krstanovic V., Habschied K., Lukinac J., Jukic M. et al. The Influence of partial substitution of malt with unmalted wheat in grist on quality parameters of Lager beer. Beverages. 2020. vol. 6. no. 1. pp. 7. doi: 10.3390/beverages6010007

- Gabriel P., Sladky P., Sigler K. A new rapid high-throughput method for prediction of beer colloidal stability. Journal of the Institute of Brewing. 2016. vol. 122. no. 2. pp. 304-309. doi: 10.1002/jib.331

- Schulte F., Flaschel E., Niehaus K. Proteome-based analysis of colloidal instability enables the detection of haze-active proteins in beer. Journal of agricultural and food chemistry. 2016. vol. 64. no. 35. pp. 6752-6761. doi: 10.1021/acs.jafc.6b02467

- Kahle E. M., Zarnkow M., Jacob F. Beer turbidity part 1: a review of factors and solutions. Journal of the American Society of Brewing Chemists. 2021. vol. 79. no. 2. pp. 99-114. doi: 10.1080/03610470.2020.1803468

- Meledina T.V., Davydenko S.G., Dedegkaev A.T. Yeast physiological state influence on beer turbidity. Agronomy Research. 2015. vol. 13. no. 4. pp. 992-1001.