The research of technological drying modes of combined fermented milk protein products with vegetable additives

Автор: Tultabayeva Т. Ch., Zhumanova U. T., Tultabayev M. Ch., Shoman А. Ye., Shoman A. K.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 2 (140), 2023 года.

Бесплатный доступ

Milk and dairy products are often dried to reduce weight, to facilitate transportation, to extend shelf life. For example, dry fermented milk products occupy a special place in the dairy industry. Currently, their assortment is significantly expanding and the approach to food products of this group is qualitatively changing. The article presents the results of drying fermented milk protein products in two ways: using thermal and microwave drying. It was found that the duration of moisture loss in the product during heat drying increased with a decrease in temperature. With an increase in temperature from 400C to 500C, there was a decrease of about 25% in the moisture content of the test samples during 5 hours of drying in the dehydrator. Drying with using of microwaves, the drying time decreased with increasing microwave power. The 900 W power reduced the drying time by 2 times compared to the 270 W power to obtain a 15% humidity result and a water activity indicator in the range from 0.382 to 0.394 units.

Fermented milk protein product, drying, microwave energy, water activity

Короткий адрес: https://sciup.org/140300134

IDR: 140300134 | DOI: 10.48184/2304-568X-2023-2-124-130

Текст научной статьи The research of technological drying modes of combined fermented milk protein products with vegetable additives

Food drying is an extremely important process in the food industry and offers opportunities to develop of new products for consumers [1,2]. Іn this regard, in rеcent years there has been an increasе in new processing technologies, the advantages of which, compared with conventional protocols, are to preserve sensory characteristics, desired texture and improved functional properties by focusing on promising areas of thе food industry [3,4].

New technologiеs can be divided into two categories: electrical technologies (pulsed electric field, radio frequency, microwave, infrared, ohmic heating), which use new heating methods and non-thermal technologies (pulsed light, high hydrostatic pressure, oscillatory magnetic field, irradiation, ozonation, plasma, osmotic treatment). Most electrical technologies focus on new approaches to heat generation and rely on traditional thermal mechanisms to achieve conservation and processing [5].

Kurt and irimshik, which are national dairy products in the regions of Central Asіa and Kazakhstan, belong to dry fermented mіlk products. These products are fermented milk products, and also represent dry young cheese, popular with all categories of the population, regardless of age, place of resіdence and material wealth [6].

The most meaningful process in the production of dry fermented milk products is drying, which brings the raw product to the of readiness, and under what conditions it takes place, the quality indicators of the finished fermented milk product depend. Based on the analysis of literature sources and patent research, it turned out that the most important process in the production of fermented milk products is drying, which brings the raw product to the stage of readiness and under what conditions it takes place, the quality indicators of the finished fermented milk product depend [7-10].

The method of processing using microwave combines the effects of electromagnetic and thermal fields, has a high efficiency both on the safety and quality of products, and on its recovery from a complex of pathogenic microorganisms, fungal, bacterial and viral etiology [5, 11-17].

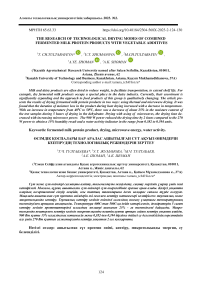

When drying in the microwave electromagnetic field, moisture is rapidly heated throughout the entire volume of the product [5]. Аt the duplicate time, due to volumetric vaporization, the moisture pressure gradient in the product increases sharply, which is the main driving factor in the dehydration of the product (Figure 1).

Figure 1 – Dehydration process during thermal and microwave drying

With conventional drying, the thermal resistance of a partially dried product often reduces the heating rate, whereas with microwave heating, the dried surface layer is characterized by less energy absorption compared to the inner layers containing a large amount of moisture [18-24]. For this reason, it is economical to use microwave heating for the final stage of drying products, but not for complete dehydration. The use of microwave heating during drying can dramatically reduce the process of dehydration of the product [25].

Materials and research methods

The drying of fermented milk protein products was carried out in two ways: thermal drying and microwave drying. Thermal drying was carried out on a Sedona Combo SD P9150 dehydrator, a BORK W502 microwave oven was used for the second method. The humidity content of the dried protein milk product was determined using a Chizhov moisture analyzer. When carrying out the drying process by two methods, the experimental samples were dried until the samples reached a constant weight in order to obtain a comparative characteristic of the various drying methods.

The water activity indicator was determined on the AquaLab device (USA), which provides

А w =P w /P 0 =P ов /100,

P w – water vapor pressure in the food product system;

P 0 – pure water vapor pressure (at the same temperature);

P ов – relative humidity at equilibrium, at which the product does not absorb moisture and does not lose it to the atmosphere, %.

А w =Rh/100,

Rh – equilibrium relative humidity, %.

measurement accuracy up to 0.003 units. The principle of operation of the device consists in using the method of a mirror-cooled dew point sensor to measure the water activity of the test sample, which is in equilibrium with the air layer of the measuring chamber, in which there is a mirror and a device detecting condensation on the mirror. In the equilibrium state, the relative humidity of the air in the chamber has the same value as the water activity of the sample. In the device, the mirror temperature is precisely controlled by a Peltier thermoelectric device. The detection of the exact value at which the first condensation appears on the mirror is marked by a photocell. The beam of light is directed to the mirror and reflected in the receiver of light radiation (in the photocell). The receiver detects a change in reflection when condensation occurs on the mirror. Then a thermoelement attached to the mirror registers the temperature at which condensation appeared, as evidenced by a light and sound signal. The display screen displays the last value of water activity and the temperature of the test sample.

The value of the water activity indicator [26] is determined by the formula:

Due to the fact that the value of water activity indicators has a thermodynamic character, since it characterizes the equilibrium vapor pressure of water at a certain temperature, it can be defined as the equilibrium relative humidity divided by 100.

The ratio of partial vapor pressures above the product and the pure solvent is included in the basic thermodynamic formula for the quantitative determination of the binding energy of moisture with the material.

*F = L = RT Ln p / p s = RT ln aw

-

*F – reduction of the free energy of the system;

L – work of separation of 1 mole of water from the material (without changing the composition);

R – gas constant;

T – absolute temperature.

Results and their discussions

Fermented milk protein products were produced with vegetable additives (carrot and pumpkin), a product without additives was used as a control sample. Prior to drying, studies were conducted to determine the humidity and water activity index in the test samples (Table 1).

Table 1 – Indicators of humidity content and water activity in cheese clots with vegetable additives

|

Dose of additives,% |

Water activity, units. |

Mass fraction of moisture, % |

||

|

with carrot additive |

with pumpkin additive |

with carrot additive |

with pumpkin additive |

|

|

0 |

0,965 ± 0,002 |

0,965 ± 0,002 |

63,1 ± 0,03 |

63,1 ± 0,03 |

|

1 |

0,963 ± 0,005 |

0,964 ± 0,003 |

65,3 ± 0,02 |

64,7 ± 0,04 |

|

2 |

0,962 ± 0,003 |

0,963 ± 0,004 |

65,7 ± 0,04 |

65,2 ± 0,02 |

|

3 |

0,960 ± 0,004 |

0,962 ± 0,001 |

66,3 ± 0,01 |

65,8 ± 0,01 |

|

4 |

0,959 ± 0,001 |

0,961 ± 0,003 |

66,8 ± 0,03 |

66,4 ± 0,04 |

|

5 |

0,958 ± 0,003 |

0,960 ± 0,004 |

71,4 ± 0,02 |

69,8 ± 0,03 |

The drying process was carried out as follows. The protein product was placed on a fine-mesh tray in the form of small slices, measuring 3 cm x 4 cm, and technological parameters were studied: duration, temperature, humidity.

Drying in a dehydrator was carried out at a temperature of 400C, 500C and 600C. In a microwave oven - at various power levels – 270W, 450W, 720W, 900W.

The mass of the samples was weighed every 60 minutes during drying in a dehydrator and 30 seconds during drying in a microwave oven until a constant value of 15% product moisture was reached.

The following indicators were analyzed in dry fermented milk protein products: water activity, structural and mechanical, as well as organoleptic indicators.

The Sedona Combo unit is designed in such a way that the warm air is distributed evenly from the back to the front wall of the device, thereby directly blowing each tray.

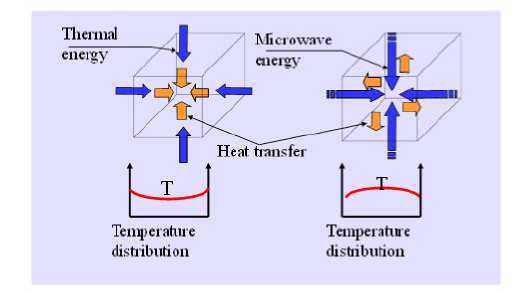

As a result of the drying process, a decrease in moisture content was observed during the hot air-drying time (Figure 2), and the lowest value of the final moisture content (15%) was observed at a temperature of 500C. It should be mentionoted that the drying time increased with decreasing temperature. It should be noted that with an increase in temperature from 400C to 500C, there was a decrease of about 25% in the moisture content of the test samples during 5 hours of drying in the dehydrator. Rapid moisture loss is also observed at the start of the drying process due to the rapid evaporation of free water in the product.

Figure 2 – Dynamics of the drying process in the Sedona Combo dehydrator

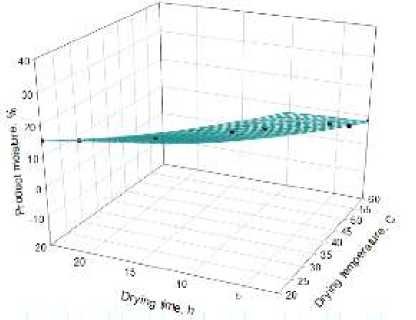

When drying using microwaves, the drying time decreased with increasing microwave power (Figure 3). 900 W power reduced the drying time by 2 times at 270 W power in order to achieve the desired result of a humidity value of 15% and a water activity indicator in the range from 0.382 to 0.394 units. As for the color of the samples, the highest values of color saturation were obtained during microwave drying.

Figure 3 – Dynamics of the drying process in a microwave oven

Table 2 - Mass fraction of moisture in dry dairy products with various drying methods

|

Dose of additives,% |

Heat drying |

Microwave drying |

||

|

Mass fraction of moisture, % |

||||

|

with carrot additive |

with pumpkin additive |

with carrot additive |

with pumpkin additive |

|

|

0 |

13,4 ± 0,03 |

13,1 ± 0,05 |

13,6 ± 0,03 |

13,3 ± 0,04 |

|

1 |

15,3 ± 0,05 |

14,7 ± 0,07 |

15,2 ± 0,06 |

14,4 ± 0,05 |

|

2 |

15,7 ± 0,04 |

15,2 ± 0,03 |

15,4 ± 0,04 |

15,1 ± 0,03 |

|

3 |

16,3 ± 0,02 |

15,8 ± 0,04 |

16,5 ± 0,01 |

15,4 ± 0,04 |

|

4 |

16,8 ± 0,06 |

16,3 ± 0,02 |

16,9 ± 0,05 |

16,7 ± 0,05 |

|

5 |

17,4 ± 0,03 |

16,8 ± 0,06 |

17,4 ± 0,03 |

16,9 ± 0,02 |

Table 3 – Indicator of water activity in dry dairy products with different drying methods

|

A prototype of a protein product |

Heat drying |

Microwave drying |

|

Control, 0% additives |

0,375 ± 0,003 |

0,382 ± 0,001 |

|

1% pumpkin/ carrot supplement |

0,381 ± 0,005 |

0,387 ± 0,002 |

|

2 % pumpkin/ carrot supplement |

0,384 ± 0,001 |

0,392 ± 0,003 |

|

3 % pumpkin/ carrot supplement |

0,378 ± 0,002 |

0,384 ± 0,005 |

|

4 % pumpkin/ carrot supplement |

0,380 ± 0,004 |

0,386 ± 0,001 |

|

5 % pumpkin/ carrot supplement |

0,383 ± 0,001 |

0,394 ± 0,003 |

Organoleptic parameters were studied in finished dry dairy products (Table 4).

Table 4 – Organoleptic parameters of dry combined fermented milk protein products

|

Indicators |

Heat drying |

Microwave drying |

||

|

with carrot additive |

with pumpkin additive |

with carrot additive |

with pumpkin additive |

|

|

Appearance |

Cracked surface |

The surface is smooth, without cracks |

||

|

Colour |

Slightly yellow |

Pale yellow |

Slightly yellow |

Pale yellow |

|

Smell |

Fermented milk |

|||

|

Taste |

With a light carrot flavor |

With a light pumpkin flavor |

With a light carrot flavor |

With a light pumpkin flavor |

High organoleptic indicators indicate the expediency of using the method of microwave drying of fermented milk protein products.

In addition, the content of the mass fraction of protein, fat and carbohydrates of dry combined fermented milk protein products was determined. (Table 5)

Table 5 – Indicators of dairy protein products with vegetable additives

|

Indicator |

Fat |

Protein |

Carboh ydrates |

Energy value, kcal |

|

Without additives |

10,8 |

34,74 |

24,13 |

326,65 |

|

With carrot additive |

7,3 |

30,53 |

23,81 |

277,11 |

|

With pumpkin additive |

9,2 |

26,72 |

24,93 |

283,17 |

A significant difference was observed in the experimental samples of fermented milk protein products without the use of vegetable additives, their dry matter content increased during microwave drying. This is mature to the lack of herbal additives that improve the moisture-retaining power in the product.

The research was carried out within the framework of the scientific and technical program BR10764998 "Development of technologies using new strains of beneficial microorganisms, enzymes, nutrients and other kits in the production of special dietary foods" of the project "Technology Development of combined fermented milk protein products of long-term storage" funded by the Ministry of Agriculture of the Republic of Kazakhstan.

Conclusion

Thus, for each drying method, the moisture content is continuously reduced by increasing the drying time. As the temperature and microwave power increased during the drying process, the diffusion rate of water in the samples increased during the drying period. The reason for this is that with an increase in the drying temperature, the humidity pressure in the sample increases significantly with an increase in microwave power, increases the rate of water diffusion by increasing the energy transferred to the product, and provides a high rate of moisture removal. When drying with hot air, an increase in temperature reduced the drying time, but this was more clearly observed for microwave power. Increasing the power of microwaves effectively reduces the drying time. It can be explained by the fact that volumetric heat generation in a wet sample due to energy transmitted directly and absorbed by water molecules leads to higher internal temperatures. Consequently, the water reaches the boiling point faster. It has been found that the drying of the product decreases with increasing temperature and microwave power. It can be said that drying in a microwave oven is the fastest and most efficient process of drying protein dairy products.

Список литературы The research of technological drying modes of combined fermented milk protein products with vegetable additives

- Tikhonov G.S., Glotova I.A., Izmailov A.N., Brekalo E.R. “Texnologiya pererabotki moloka s vy`puskom suxogo molokosoderzhashhego produkta” [Technology of milk processing with the release of a dry milk-containing product] // European Journal of Natural History. – 2021. – No. 5. – PP. 29-33.

- Tultabayeva T.C., Chomanov U.C. “Thermodynamic and rheological characteristics of combined soft cheeses (In Russian) (2011) // Science News of Kazakhstan, 2, - PP. 1-8.

- Tultabayeva T.C., Tultabayev,M.C., Zhumanova U.T.Influence of the additive on “water activity in food products (In Russian) (2001) // International Scientific-Practical Conference Proceedings, Almaty, 2001. -Р. 74.

- Tultabayeva, T., Chomanov, U., Kenenbay, G., Zhumaliyeva, G., Shoman, A. Formulation of multicomponent mixture in the production of combined soft cheese // Journal of Hygienic Engineering and Design, 29, 2019. -PP. 125-131.

- Ushakova N.F., Kopysova T.S., Kasatkin V.V. Opy`t primeneniya SVCh-e`nergii pri proizvodstve pishhevy`x produktov [Experience of using microwave energy in food production] // Food industry.-2013.-No.10.-РР. 30-32.

- Belyaeva M.A., Samuel Ali Malazi «Optimizaciya i apparaturnoe oformlenie infrakrasnoj sushki NACIONAL`NOGO kislomolochnogo produkta (kurta)» [Optimization and hardware design of infraded drying of the national fermented milk product (kurta)], Russin of economics type.-2017.-No 10.-РР. 41-45.

- Patent No. 2357421 of the Russian Federation A23C1/00. Method of vacuum drying of cottage cheese / O.N.Buyanov (RU), A.N.Splavkin (RU), V.A.Ermolaev (RU), S.A.Zakharov (RU), L.M.Arkhipova (RU); Application 13.11.2007; Publ.10.06.2009.

- Patent No. 2411740 of the Russian Federation A23C1/10. Method of removing moisture from dairy products / O.N.Buyanov (RU), A.N.Splavkin (RU), V.A.Ermolaev (RU), S.A.Zakharov (RU), L.M.Arkhipova (RU); Application 29.10.2009; Publ.20.02.2011.

- Patent No. WO 2011/014045, A23C 23/00 (2006.01), A23C 9/12 (2006.01). Kurt's production method: No. PCT/KZ 2010/000012: declared 29.07.2010: published 03.02.2011/Shalbarbayev AA; applicant Shalbarbayev AA-11c.

- Patent no. KZ 27564, A23C 9/13 (2006.01), A23C 19/02 (2006.01). Kurt's production method: no. KZ 22857: declared 11.02.2013: published 15.10.2013/Kiseleva K.A.; applicant Tamasha Pasta Factory LLP, bul.no.10.

- Assis F.R., Morais R.M.S.C., Morais A.M.M.B.: Microwave drying of apple cubes – effect of the osmotic pre-treatment and comparison with hot air drying, Advances in Food Science and Engineering, 2017, in press;

- Marcos A. Water activity in cheese in relation to composition stability and safety P.F. Fox (Ed.), Cheese: Chemistry, physics and microbiology, Vol. 1, Chapman & Hall, London, UK (1993), -РР. 439-471.

- David M Barbano , Mary E Della Valle 1 Microwave Drying to Determine the Solids Content of Milk and Cottage and Cheddar Cheese // J Food Prot 1984 Apr;47(4):272-278. doi: 10.4315/0362-028X-47.4.272.

- Hayward LH, Kropf DH. Sample Position Effects on Moisture Analyses by a Microwave Oven Method 1, 2.J Food Prot. 1980 Aug;43(8):656-657. doi: 10.4315/0362-028X-43.8.656.PMID: 30822974

- Rogov I.A. Znachenie pokazatelya «aktivnost` vody`» v ocenke sel`skoxozyaĭstvennogo sy`r`ya [The value of the indicator "water activity" in the evaluation of agricultural raw materials]: Overview information / I.A. Rogov, U.Ch. Chomanov, A.M. Brazhnikov et al. - M.: Agroniteimmp, 1987. – 44 p.

- Ashtiani S. H. M., Sturm,B., & Nasirahmadi A. . Effects of hot-air and hybrid hot air-microwave drying on drying kinetics and textural quality of nectarine slices. // Heat and Mass Transfer/Waerme- Und Stoffuebertragung, 54(4), 2018: 915–927.

- Кumar C., & Karim M. A. (2019). Microwaveconvective drying of food materials: A critical review. Critical Reviews in Food Science and Nutrition, 59(3), 379–394. https:// doi.org/10.1080/10408398.2017.1373269

- Nieto A. B., Vicente S., Hodara K., Castro M. A., & Alzamora S. M. Osmotic dehydration of apple: Influence of sugar and water activity on tissue structure, rheological properties and water mobility. // Journal of Food Engineering, 119(1), 2013:104–114. https://doi.org/10.1016/j.jfoodeng.2013.04.032

- Saha, S. K., Dey, S., & Chakraborty, R. (2019). Effect of microwave power on drying kinetics, structure, color, and antioxidant activities of corncob. Journal of Food Process Engineering, 2022: Article e13021. https://doi.org/10.1111/jfpe.13021.

- Vermeulen, A., Marvig, C. L., Daelman, J., Xhaferi, R., Nielsen, D. S., & Devlieghere, F. (2015). Strategies to increase the stability of intermediate moisture foods towards Zygosaccharomyces rouxii: The effect of temperature, ethanol, pH and water activity, with or without the influence of organic acids. // Food Microbiology, 45(PA), 2015: 119–125. https://doi.org/10.1016/j.fm.2014.01.003

- Zarein, M., Samadi, S. H., & Ghobadian, B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices. // Journal of the Saudi Society of Agricultural Sciences, 14(1), 2015.–РР. 41–47. https://doi.org/10.1016/j.jssas.2013.06.002

- Zhou, X., Li, R., Lyng, J. G., & Wang, S. Dielectric properties of kiwifruit associated with a combined radio frequency vacuum and osmotic drying. // Journal of Food Engineering, 239, 2018. -РР. 72–82. https://doi.org/10.1016/j.jfoodeng. 2018.07.006. September 2017.

- Zielinska, M., Ropelewska, E., Xiao, H.-W., Mujumdar, A. S., & Law, C. L. Review of recent applications and research progress in hybrid and combined microwave- assisted drying of food products: Quality properties. // Critical Reviews in Food Science and Nutrition, 2019: 1–53. https://doi.org/10.1080/10408398.2019.1632788, 0(0).

- Bando, K., Kansha, Y., Ishizuka, M., & Tsutsumi, A. Innovative freeze-drying process based on self-heat recuperation technology. // Journal of Cleaner Production, 168, 2017. -РР. 1244-1250. http://dx.doi.org/10.1016/j.jclepro.2017.09.088.

- Rakhmankulov D. L., Shavshukova S. Yu., Vikhareva I. N. Application of microwave radiation in the food industry // Bash. chem. zh. 2008. -No. 1.

- Feeney, E. L., Lamichhane, P., & Sheehan, J. J. The cheese matrix: understanding the impact of cheese structure on aspects of cardiovascular health – a food science and a human nutrition perspective. International Journal of Dairy Technology, 74(4), 2021: 656- 670. http://dx.doi.org/10.1111/1471-0307.12755.