Development of a new variety of meat and vegetable cutlets

Автор: Kenenbay Sh. Y., Gornikov N. V., Yemelina V. V.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 2 (140), 2023 года.

Бесплатный доступ

Modern problems of the food industry in Kazakhstan are considered. To solve these problems, a recipe for new meat chopped semi-finished products using dietary fiber has been developed. The analysis of physical and chemical indicators of samples of cutlets for fast food presented on the market of Kazakhstan was carried out. When comparing the mass fractions of protein in semi-finished meat products, an increase in the amount of protein was revealed when soy texturate has added. The relevance of the scientific article is that the meat industry is considered a strategic direction of the agricultural sector of the economy of the Republic of Kazakhstan, which is part of the food security system. One of the main tasks set before the researcher was to choose the best proportion of soy texturate in the minced meat semi-finished product. The article provides an organoleptic evaluation of the control and experimental samples, on the basis of which a choice was made regarding the percentage of replacement of minced meat with soy texturate.

Minced beef, soy texturate, chopped semi-finished meat products, fast food, meat industry

Короткий адрес: https://sciup.org/140300149

IDR: 140300149 | DOI: 10.48184/2304-568X-2023-2-5-10

Текст научной статьи Development of a new variety of meat and vegetable cutlets

The pandemic 2019-2021 significantly affected the food industry in Kazakhstan. Before the pandemic, up to 19,000 restaurants, bars, and cafes operated in Kazakhstan. At the moment, about 60% of them have suspended their activities, and 20% have closed. At the same time, it should be noted that about 950 new public catering enterprises appeared on the market during the pandemic, according to the Bureau of National Statistics of the Agency for Strategic Planning and Reforms of the Republic of Kazakhstan [14].

When exiting the pandemic, the challenge facing catering establishments is consumer satisfaction based on the “price-quality” principle, i.e. cost reduction while maintaining high consumer properties. Since one of the main products used in catering in Kazakhstan is meat, it is relevant to develop new semi-finished products and dishes based on this type of raw material.

According to the FAO/WHO, by 2050 the consumption of meat and meat products should increase to 52 kg per capita [13]. An increase in cattle production is expected, but the growth rate of agricultural production is much lower. Increasing demand requires an increase in meat production worldwide by two hundred million tons. At the same time, this increase will require the intensification of the use of land and water resources, it will definitely be accompanied by the aggravation of existing and the formation of new environmental problems.

The meat industry is one of the leading sectors of Kazakhstan's economy in the field of material production, and the development of the meat industry depends on the full diet of the population with products such as meat and semi-finished meat products as well as dairy products. The aim is to guarantee the quality and safety of the meat products. The production of meat products consists of a chain of numerous divisions, from the production of raw materials for food and food to the sale itself, including equipment used, packag- ing materials, preservatives, additives, etc. All links in the structure of meat and meat products are interconnected, which helps to ensure the quality of these products. In Kazakhstan, the production and consumption of meat and meat products is associated with the ethnic characteristics of the diet of its inhabitants.

One of the solutions to this problem in the scientific direction is the development of combined food products, for example, meat and vegetable semi-finished products. The result can be not only a reduction in cost, but also an improvement in the consumer properties of finished products. Thus, one of the more common types of vegetable raw materials is soybean - a legume of world importance, which has a high content of complete protein. Soy proteins are highly nutritious and digestible; the digestibility index of soy protein is close to the digestibility of cow's milk and is at the level of 91-96% [1-3].

According to the Agency for Strategic Planning and Reforms of the Republic of Kazakhstan, the Bureau of National Statistics, for the first quarter of 2021 in Kazakhstan, the consumption of meat and meat products amounted to 20.5 kg per capita, which is 1.9 kg more compared to the same period last year [14] . This indicates the demand for meat products in the food market and the feasibility of expanding the range. Currently, insufficient intake of essential substances with food is a problem in all civilized countries. Bridging the gap between protein intake and its actual need can be achieved through the use of various soy-containing food additives in the formulation of meat products as new sources of protein for human nutrition [4].

To obtain a new type of cutlets with the addition of a vegetable component, it is necessary to consider the existing cutlets used for fast food.

Meat and meat products are the most valuable food products, so it is extremely important not only to preserve their original properties, but also to improve them during technological processing.

From animal proteins in the human body, substances are synthesized that promote the production of neurotransmitters serotonin, dopamine, epinephrine and norepinephrine, which have a beneficial effect on the central nervous system.

The development of recipes for semifinished products from minced meat, involving the replacement of part of the raw materials with vegetable additives, is a promising way to solve the problem of increasing the availability of meat products, expanding their range and increasing nutritional value.

Materials and research methods

The object of the study was beef cutlets of different brands of fast food in Kazakhstan. A cutlet with soy texturate served as a control; a meat cutlet used in public catering establishments of the Kazakhstan market served as a control.

Laboratory research methods were used in the experiment. When determining the physicochemical parameters of control and experimental samples, the content of protein and fat was determined according to state standards 25011 - 2017

and 23042 - 2015; the content of carbohydrates was determined by the permanganate method

Results and their discussions

The basis of the new meat-and-vegetable cutlet for a burger was a cutlet, which is already used in the market of Kazakhstan. The composition of this cutlet includes minced beef , a mixture of five ground peppers, mustard powder, salt, liquid smoke, vegetable oil of the first pomace. A complete technological map is given in the article of the international scientific research journal “Development of technology of chopped semifinished meat with the additation of soy texturate for fast food enterprises”.

Minced meat for this cutlet is used in the ratio of 80/20, in which 80% lean meat and 20% body beef fat, this minced meat is produced by KazBeef LTD LLP, which has a food safety certificate FSSC 22000.

The results of physical and chemical analysis of the control sample of cutlets in raw and fried presented in tables 1,2. The mass of one cutlet is 0.1 kg.

Table 1 - Physical and chemical parameters of the control and experimental raw semi-finished products

|

Name of indicators, units of measurement |

Actual Control Sample Results |

Actual results of the experimental sample |

|

Mass fraction of protein,% |

9.91±0.11 |

13.01±0.19 |

|

Mass fraction of fat, % |

11.08±0.15 |

14.38±0.18 |

|

Mass fraction of carbohydrates, % |

5.61±0.07 |

3.28±0.03 |

From table 1 we can conclude that in the experimental sample there is 3.1% more protein than in the control sample, which indicates a positive effect of soy texturate on the composition of chopped semi-finished meat.

Table 2 - Physical and chemical parameters of the control and experimental fried semi-finished products

|

Name of indicators, units of measurement |

Actual Control Sample Results |

Actual results of the experimental sample |

|

Mass fraction of protein,% |

12.84±0.15 |

17.45±0.26 |

|

Mass fraction of fat, % |

13.14±0.19 |

15.04±0.16 |

|

Mass fraction of carbohydrates, % |

5.04±0.05 |

2.94±0.02 |

Drawing a conclusion from Tables 1 and 2 in the finished semi-finished meat product with the addition of soy texturate, the mass fraction of protein is also higher than in raw. The positive effect of soy texturate on the nutrient composition of semi-finished meat products is obvious.

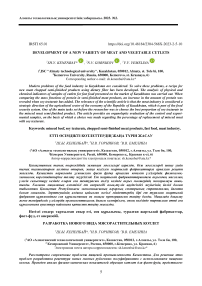

Figure 1 shows the moisture-binding capacity of cutlets to which soy texturate has been added.

From figure 1 it follows that with an increase in the percentage of addition of soy texturate, the moisture-binding capacity of minced meat semifinished products increases. It can be concluded that meat minced semi-finished products will be more juicy, since the moisture-binding capacity affects the water retention during cooking.

To develop a new type of meat-and-vege-table patty, Rosstex soy texturate was used as a source of vegetable protein, which complies with State Standard 8057-95.

Figure 1 - Water-binding ability of chopped semi-finished meat products using soy texturate

20% soy texturate by weight of minced meat ratio was the most optimal, studies of organoleptic was added to the control sample of cutlets. This indicators are shown in table 3.

Table 3 - Organoleptic characteristics of the experimental and experimental sample of cutlets with the addition of soy texturate

|

Product name |

Organoleptic evaluation according to 9 point system |

|||||

|

Colour |

Aroma |

Taste |

Juiciness |

The form |

Overall quality score |

|

|

Prototype |

8 |

8.5 |

8.5 |

6 |

8 |

7.8 |

|

experimental sample |

||||||

|

15% |

7.5 |

8.5 |

8.5 |

6 |

8 |

7.7 |

|

20% |

8 |

8.5 |

8 |

7 |

8 |

7.9 |

|

25% |

8 |

7 |

6.5 |

7.5 |

6 |

7 |

Analyzing the research results, it can be seen that the use of texturate has a positive effect on the amount of protein in cutlets. The scientific literature describes that soy proteins of extruded products have high fat absorption rates, which is apparently due to the fact that soy protein molecules, along with hydrophilic ones, also have hydrophobic functional groups that are able to retain, capture and bind fat molecules. The absorbing capacity of granular texturate is 82%, this fact explains the increase in the proportion of fat in the experimental sample.

The analysis of the yield of finished cutlets was carried out. Both samples of cutlets had a raw weight of 0.1 kg. After frying, the control sample of the patty had a weight of 0.068, and the experimental one 0.074 kg. Conclusion is that cutlets with the addition of soy texsurate are economically viable.

To understand the competitiveness of the new meat and vegetable cutlets in the market of Kazakhstan, physical and chemical studies of ready-made cutlets from various fast food restaurants were carried out.

Table 4 - Comparative analysis of ready-made semi-finished meat products presented on the market of Kazakhstan

|

Physical and chemical indicators |

Cutlet sample number |

|||

|

1 |

2 |

3 |

Experimental cutlet |

|

|

Mass fraction of protein, % |

17.12 ± 0.22 |

12.1 ± 0.19 |

14.28 ± 0.16 |

17.45±0.26 |

|

Mass fraction of fat, % |

23.69 ± 0.18 |

9.3 ± 0.05 |

9.08 ± 0.05 |

15.04±0.16 |

|

Mass fraction of carbohydrates, % |

2.34 ± 0.03 |

2.5 ± 0.03 |

2 ± 0.03 |

2.94±0.02 |

According to table 4, it can be seen that the experimental cutlet is superior to other samples in terms of the amount of protein. In terms of fat content, sample number 1 outperformed the other samples.

It is described in the scientific literature that soy proteins of extrusion products have high fat absorption capacity, which is obviously explained by the fact that soy protein molecules, along with hydrophilic ones, also have hydrophobic functional groups that are able to hold, capture and bind lipid molecules. The fat absorption capacity of texturate in the form of granules is 82%, i.e. the maximum amount of absorbed oil per 1 g of tex- turate in the form of granules is 0.82 g. This fact explains the increase in the percentage of fat in experimental samples.

It can be concluded that the experimental cutlet is superior in terms of protein.

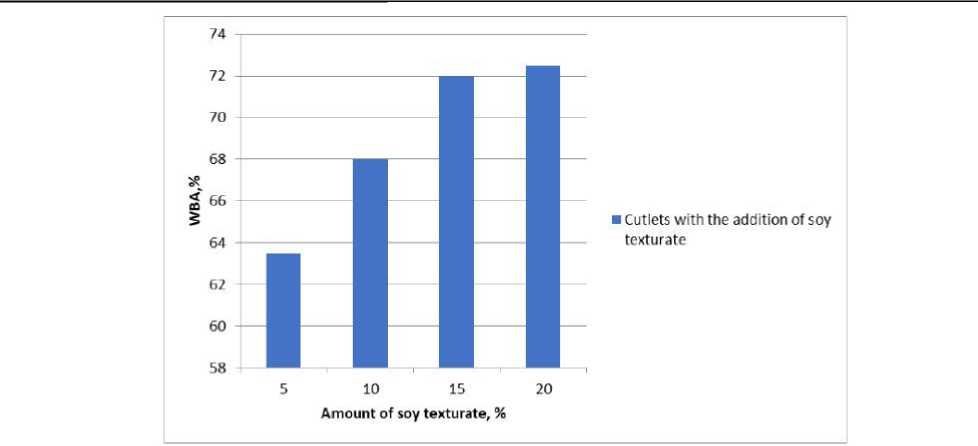

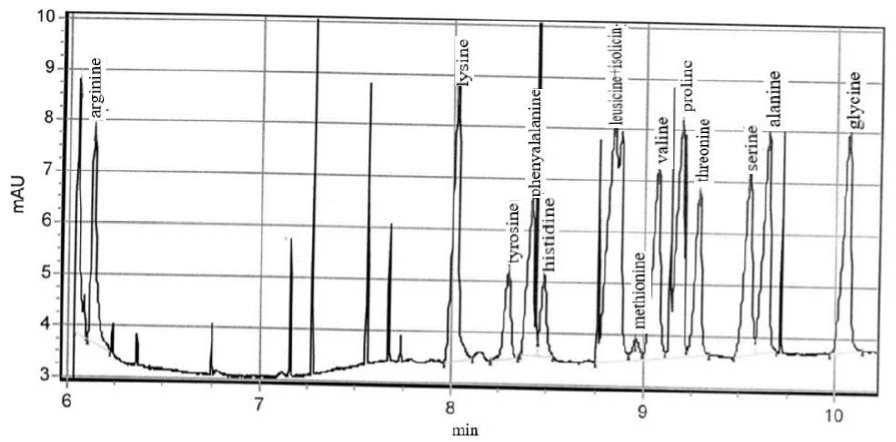

For a broader understanding, studies of the amino acid composition presented in Figures 2 and 3 were carried out.

Figure 2 - Amino acid composition of the control sample of fried

Figure 3 - Amino acid composition of the control sample of fried

According to the figures, it can be concluded that in the experimental sample, arginine is 0.387% more, lysine is 0.056% more, glycine is 0.577% more, alanine is 0.457% more. Based on this, we can conclude that the experimental sample of the cutlet has a positive effect on the amino acid composition of the cutlet, supplementing animal protein with vegetable protein, which will make the human diet more balanced.

Table 5 shows the data on the mass fraction of moisture in the experimental and control fried samples.

Table 5 - Comparative analysis of ready-made semi-finished meat products presented on the market of Kazakhstan

|

Name of indicators, units of measurement |

Actual results of the control sample |

Actual results of the experimental sample |

|

Mass fraction of moisture,% |

43,84±0,05 |

45,79±0,08 |

According to Table 5, it can be concluded that the mass fraction of moisture is greater in the experimental samples than in the control ones. The mass fraction of moisture in finished products affects the output of products, since with an increase in the moisture content in manufactured products, their output increases.

Conclusion

As a result of the research, it was found that the introduction of soy texture into a meat patty

Список литературы Development of a new variety of meat and vegetable cutlets

- Aleshkov A.V., Kalenik T.The G., Matkina E.V. Innovasii V pitshevoy industrii: sistemnoe obobtshenie [Innovations in the food industry: system generalization] // Vestnik Kamchatskogo gosudarstvennogo technicheskogo University. -2016. -№36.-РР. 41-44 [in Russian].

- Bichkova, E. The A., Borisova, A. V. Belkovie concentrate Soi: technolii proizvodstva I prospect primeneneniya [Soy protein concentrates: production technologies and application prospectus] // Polzunovsky Vestnik. -2021. -№ 2. -РР. 88-94 [in Russian].

- Pilipenko A.The A. Sposobi pererabotki soevogo shrota dlya polucheniya pitshevikh Belkov [Methods for processing soybean meal to obtain nutritional proteins] // Mejdunarodny magazine prikladnix Nauk I technological "Intégral". -2019. -№ 1. РР. 79-83 [in Russian].

- Emelina V. V. , Kenenbay S.Y. Development of technology of minced meat semi-finished product with the addition of soy texturate for fast food enterprises // International Research Journal. — 2021. — № 7 (109) Part 1. — РР. 69-72 [in Russian].

- Samchenko, O. N. Rublenye polufabrikaty s semenami maslichnykh kul’tur // Tekhnika I tekhnologija pishhevykh proizvodstv [Equipment and technology of food production]. – 2016. – №4. (43) РР. 64-68 [in Russian].

- Reshetnik, E. I. Vlagouderzhivajushhaja sposobnost’ kak kriterijj kachestva mjaso-rastitel’nykh polufabrikatov [Water-holding capacity as a criterion for the quality of meat and vegetable semi-finished products] / Potencial sovremennojj nauki [The potential of modern science]. – 2015. – № 2 (10) РР. 127-131 [in Russian].

- Gabdukaeva L.Z. Funkcional’notekhnologicheskie svojjstva mjasnykh polufabrikatov, obogashhennykh rastitel’nymi komponentami [Functional and technological properties of meat semi-finished products enriched with vegetable components] / XXI vek: itogi proshlogo i problemy nastojashhego pljus 2018. -Vol. 7. -No. 4(44) РР. 216-218 [in Russian].

- Pritykina, N. A. Razrabotka tekhnologii mjasnogo polufabrikata vysokojj stepeni gotovnosti [Development of technology of meat semi-finished product of high degree of readiness]// Izvestija Kaliningradskogo gosudarstvennogo tekhnicheskogo universiteta [Proceedings of the Kaliningrad State Technical University]. – 2016. – No. 40. – PP. 69-80 [in Russian].

- Masalova, V. V. Perspektivy ispol’zovanija bezgljutenovogo rastitel’nogo syr’ja v proizvodstve pishhevykh produktov dlja dieticheskogo i profilakticheskogo pitanija [Prospects for the use of glutenfree vegetable raw materials in the production of food products for dietary and preventive nutrition] / / Pishhevaja promyshlennost’ [Food industry]. – 2016. – No. 3. – PP. 21-26 [in Russian].

- Production of biologically active peptides by hydrolysis of whey protein isolates using hydrodynamic cavitation / A.B. Muley & all / / Ultrasonics Sonochemistry, 2021. -V. 71. -105385.

- Messina, M. Soy and Health Update: Evaluation of the Clinical and Epidemiologic Literature / M. Messina / / Nutrients. – 2016. - Val. 8, № 12. - P. 754.

- Shynar Kenenbey. Evaluation of autolysis induced histologic alterations in skeletal muscle tissue of non‑traditional meat animals/ Leila Kaimbayeva1, Shynar Kenenbay, Daniyar Zhantleuov, Aigul Tayeva, Nursulu Akhmetova, Zhanar Medeubayeva // Food Sci. Technol, Campinas, 40(3): 736-740, July-Sep. 2020.

- Wittenberg, K. Meat and the Environment – Future directions / K. Wittenberg // in 58th International Congress of Meat Science and Technology – Montreal, Canada, 2012. -РР. 66-73.

- Bureau of National Statistics of the Agency for Strategic Planning and Reforms of the Republic of Kazakhstan/ https://stat.gov.kz/.

- Arman Issimov, Torebek Baibatyrov, Aigul Tayeva,, Shynar Kenenbay and ort. Prevalence of Clostridium perfringens and Detection of Its Toxins in Meat Products in Selected Areas of West Kazakhstan. Agriculture 2022. -12. -1357: 2-7 РР. https://doi.org/10.3390/agriculture12091357 https://www.mdpi.com/journal/agriculture Journal Rank: JCR - Q1 (Agronomy) / CiteScore - Q2 (Plant Science) ISSN: 2077-04727