Influence of the smoking process on the content and quality of polycyclic hydrocarbons in Bulgarian fermented sausages

Автор: Dontchyeva T., Valkova-yorgova K., K. Danov D. gradinarskA., Milkova-toneva I., Okanovitch D.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Естественные науки

Статья в выпуске: 5 (101), 2013 года.

Бесплатный доступ

The present article studies the influence of the smoking on the content and quantity of PAH with toxic action in dry fermented and smoked meat sausages. The results obtained demonstrate that higher quantities of accumulation of benzo/a/pyrene /BAP/ and dibenzo(а,I)-pyrene are found in samples of raw- fermented and smoked sausage „Petrohan” in comparison with flat sausage ‘Smyadovska’ samples. We consider that the use of artificial casings ‘fibrous’ in the production of raw-fermented and smoked meat sausages is an effective method for significant reduction in the content of polycyclic aromatic hydrocarbons in final products in comparison to those stuffed in natural sausage casings.

Dry fermented smoked meat sausages, pah, benzo(a) pyrene

Короткий адрес: https://sciup.org/140205018

IDR: 140205018 | УДК: 637.049

Текст научной статьи Influence of the smoking process on the content and quality of polycyclic hydrocarbons in Bulgarian fermented sausages

The improvement in the manner of smoking with a view to improving environmental cleanliness and biological value of meat products may be achieved through the use of appropriate smoking mixtures containing the least quantity of substances harmful for the health of the consumer. These adverse effects worsen the hygienic condition of the finished products and reduce their nutritional value. Some hydrocarbons contained in the smoke for smoking, especially polycyclic aromatic hydrocarbons (PAH), pertain to the substances unwanted for smoked products. Thus 3, 4-benzopyrene contained in smoke as well as in smoked products has carcinogenic properties [12]. Some particles of the PAH molecule possess more significant reactivity- this is the site where they bind with cellular elements such as nucleotides, DNA and RNA. This process may induce cancer formation in cells [3].

Together with carcinogenic activity of these hydrocarbons, the presence antagonistic and synergic role of some toxic or nontoxic substances must be noted [2, 4].

It should be pointed out that it is difficult to determine the real danger which exists in the consumption of smoked food products in which there is PAH. In addition, the content of 3, 4 benzopyrene is in too broad ranges depending on the technology used and kind of product, the kind of the wood used etc. [5]. Due to these reasons the German legislation consider necessary with a view to safety to restrict the presence of 3, 4 benzopyrene to 5 µg/kg in meat products [6].

Owing to the highly toxic properties of PAH to human health their identification and establishing methods for reduction of their content, ranks them among the most topical problems in the contemporary nutritional science.

The aim of the present article is to study the influence of smoking with smoke produced in the incomplete burning of oak chips on the content and quantity of polycyclic aromatic hydrocarbons with toxic action in raw fermented and smoked meat products from minced meat.

Materials and methods

The research is conducted with durable raw- fermented sausage ‘Petrohan’ and raw-fermented flat sausage ‘Smyadovska’.

For the production of raw- fermented flat sausage ‘Smyadovska’ chilled beef and pork, solid pork fat derived from healthy animals are used.

The sorted 1-st quality beef is cut into pieces of 100-150 gr. The sorted non-fatty pork is also cut into pieces of 100-150 gr. The solid pork fat derived from the back, neck and breasts, cleaned well from bloody and bruised soft parts, is cut into small pieces of 30-40gr.

The 1-st class beef pieces cut in this manner and the pork non-fatty meat are placed in grid containers in a layer no thicker than 15cm and are regrigerated at temperature of 0-2°C for 24 hours in order to reduce the water content of the meat and to gain firmer texture.

The solid pork fat cut in pieces is placed in refrigerator at 6º С for freezing for 24h.

The dried and firm raw materials are processed for stuffing in the following manner: beef is grinded in a wolf machine through a grid with openings of 5-6mm. The frozen pork fat is processed in a cutter machine until it is cut into pieces of 10mm, the beef, which is minced in advance, is then added, and after 3-4 turnovers of the plate of the cutter salt, salt, pepper, spices and sugar are added and the end the pork non-fatty meat is put which has been mined in advance. The process of cutting continues until the texture becomes granular with size of the pork fat 3mm.

The prepared stuffing mix is filled tightly in beef thick casings or in suitable artificial casings type ‘fibrous’ with diameter 45mm.

After draining the flat sausages are placed for smoking in smokers. Smoking is done with oak sawdust for 24 hour period at 15º С.

Drying is performed in air driers at t = 12º С and 75 % relative air humidity for up to 30d until the water content reaches 33% from the total weight. During the process of drying flat sausages are pressed three times.

For the production of raw fermented sausage ‘Petrohan’ chilled beef, pork and spices are used according to the recipe.

The sorted beef is cut into pieces of 150-200gr. refrigerated at temperature of 0º С to - 4º С and is salted in advance. The process ‘ripening’ is performed there. The sorted pork is cut into pieces of 100-120gr. and put in grid trays in thickness of 10-15cm. It is refrigerated at 0º С до +2º С to reduce humidity and get firm texture for 20-24h.

The salted beef is grinded in the wolf though a grid with size of the openings 4mm and is placed in the stirrer. The firm pork, which is minced in a wolf machine though a grid with size of the openings 10mm, is then added. The salting materials and spices are added and the stirring continues for 2-3 more minutes.

The prepared stuffing mixture is placed in a refrigerator for ‘ripening’ at temperature of +3 до +4º С for a period of 24h.

What follows is a process of stuffing in pork small intestine with length of the pieces, which are formed by turning, 30cm. The diameter of the casings is 30mm. The ready stuffed pieces are hanged on sticks and arranged to drain and dry for about 24h.

The dried pieces are smoked by the use of oak sawdust in smokers at temperature of 12º С for 2 days.

After smoking the pieces remain in the drier for 7 days at temperature of 12º С and relative air humidity 75% till the water content reaches 38%.

For the qualitative identification and quantification of polycyclic aromatic hydrocarbons the studied samples are processed in the following manner: 200gr. from each sample is grinded with mixer afterwards 25gr. is weighed and placed in a cellulose vial. Afterwards to them 200 cm³ acetone is added and extraction is performed for 5h at room temperature. The extract obtained is evaporated till dry substance remains with vacuum evaporator at water bath temperature 40º С. The obtained dry residue is soaped (hydrolyzed) with 100 cm³ KOH ethanol solution for 5 min at water bath temperature 60º С. The solution is then transferred in a separatory funnel and is added 100 cm³ cyclohexane и 100 cm³ distilled water with temperature of 60º С; it is then stirred and left for decantation. If emulsion is formed 10 cm³ ethanol is added. Afterwards water phase is separated and organic phase is filtered by anhydrous sodium sulphate filter. The filtrate produced is vaporized to dry substance in rotary vacuum evaporator at water bath temperature 40º С. The obtained dry residue is afterwards diluted in 2 cm³ mixture of ethanol and tertahydrofuran in proportion 1:1. 6 µl of this solution are injected in gas chromatograph Hewlett Packard 5890 at the following parameters:

-

- pump- series 4, Perkin Elmer USA

-

- detector- spectro photometric LG 85 B

Analysis is performed in the following conditions of chromatography:

-

- column НС – ООС 25 х φ 2,6 mm

-

- mobile phase consisting of mixture of water and acetonitrile in the conditions described below:

|

Min. |

% CH 3 CN |

% H 2 O |

|

10 |

50 |

50 |

|

3,0 |

50 |

50 |

|

7,0 |

100 |

0 |

|

25,0 |

100 |

0 |

|

5,0 |

50 |

50 |

- injected volume 6 µl

-

- spectrophotometric determination at λ = 254 nm

For identification of peaks resulting from injecting the sample in the liquid chromatograph the times for retention of witnesses and the method of the internal additive are used.

The quantity of the identified polycyclic aromatic hydrocarbons is defined according to the method of the external standard.

Defining the moisture content is performed according to AOAC [7].

To define the fat content the classical method for fat extraction with diethyl ether in the Soxhlet apparatus was used [7].

The content of total protein was defined according to the Kjeldahl method [7].

To identify the content of table salt in the studied experimental and control samples sausages the method for titration of chloride ions with silver nitrate solution in the presence of potassium chromate indicator was used [7].

Determination of the level of nitrites in products is done according to AOAC [7]. The results obtained are mathematically and statistically processed [8].

Results and discussion

The nature and dynamics of accumulation of smoke substances in the stuffing mass for raw fermented meat products from minced meat exerts significant influence on the formation of quality indicators during the technological process smoking and drying in the production of raw fermented sausages. The experimental results from the research of the changes in some chemical indicators established by the regulations for durable rdy-fermented sausage ‘Petrohan’ and raw-fermented flat sausage ‘Smyadovska’ as dry substance, protein content, fat sodium chloride, nitrite content etc. are presented in Table 1.

They show that the application of technological operation ‘smoking with use of smoke, produced in the incomplete combustion of oak sawdust does not exert significant influence on the indicators total protein and fat content in the ready products from the experimental and control samples.

The results show that there are no significant differences in the chemical content of ready sausages from both studied assortment, produced with smoke from oak sawdust. For example the content of total protein in the control and experimental samples from ‘Petrohan’ sausage are 30, 50±0, 30 and 30, 61±0, 25 respectively and with raw-fermented flat sausage “Smyadovska’ 29, 48 ± 0, 30 and 29, 64 ± 0, 29 respectively (Table 1).

Table 1 - Chemical content of smoked raw-fermented sausages

|

Indicators |

‘Petrohan’ sausage |

‘Smyadovska” flat sausage |

||

|

Control samples (without smoke) |

Experimental samples (with smoke) |

Control samples (without smoke) |

Experimental samples (with smoke) |

|

|

1. Water content (% from the total weight) |

37,32 ± 0,71 |

37,46 ± 0,96 |

33,20 ± 0,31 |

33,29 ± 0,33 |

|

2. Protein (%from the total weight) |

30,50±0,30 |

30,61±0,25 |

29,48 ± 0,30 |

29,64 ± 0,29 |

|

3. Fat (% in dry substance) |

56, 01 ± 0,72 |

56,21 ± 0,83 |

54,38 ± 0,22 |

54,54 ± 0,10 |

|

4. Minerals (% in dry substance) |

2,10 ± 0,09 |

2,19 ± 0,10 |

2,20 ± 0,05 |

2,23 ± 0,04 |

|

5. Sodium chloride (% from the total weight) |

3,10±0,01 |

3,06±0,03 |

2,98±0,03 |

2,95±0,04 |

|

6.Nitrites (mg/100g product) |

4,92± 0,03 |

4,90± 0,04 |

4,91± 0,02 |

4,89± 0,05 |

A similar tendency is established with the other physicochemical indicators as water content, fat content etc. Considering the results from table 1 it can be noted that the application of the technological operation’ smoking with the use of smoke produced in the incomplete combustion of oak sawdust does not exert significant influence on the reaching of standard values for physicochemical parameters.

The obtained data on the physicochemical content of the studied raw- fermented and smoked meat products provide information on the nutritive values of the studied meat products. The analysis of the results shows that smoking with smoke from oak sawdust does not lead to statistically significant differences concerning the chemical content of the smoked experimental samples.

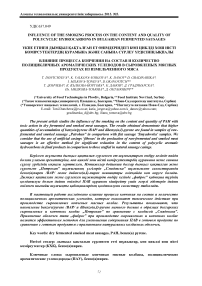

The data presented in fig. 1 show that the smoking of raw-fermented sausages with smoke, produced in the incomplete combustion of oak sawdust leads to significantly higher content of different polycyclic aromatic hydrocarbons in durable dry-fermented sausage ‘Petrohan’ in comparison to raw- fermented flat sausage ‘Smyadovska’. A possible reason for this is the application of continuous smoking process connected with the lengthening of the contact period of smoke substances with meat components of the raw-fermented sausage ‘Petrohan’.

Fig.1 - Changes in the PAH quantity in raw-fermented and smoked sausages with smoke, produced in the incomplete combustion of oak sawdust (µg/kg).

The question on the proportion of the concentration of benzopyrenes and polycyclic aromatic hydrocarbons (PAH) appears a key one as far as the presence of such information would allow with enough grounds to use benzo(a) pyrene in the study of the regulations for the distribution of carcinogenic PAH in raw-fermented and smoked meat products and the evaluation of their environmental hazard [9]. Therefore in the present study we defined the quantity and quality content of the following PAH: benzo/а/-anthracene /ВаА/, Chrysene/СНR/, Cyclopenta/c,d/pyrene (CPP), Methyl-chrysene /5MC/, Benzo/в/-flouranthene /BbF/, Benzo/к/-fluoranthene/ВкF/, Benzo/j/-fluoranthene /BjF/, Benzo/а/pyrene /ВаР/, Dibenz/a,h/-anthracene/DhA/, Indeno/1,2,3-c,d/-pyrene/IcP/, Benzo/g,h,i/-perylene/BgP/, Dibenzo /a,I/-pyrene/DIP/, Dibenzo /а,е/-pyrene /DeP/, Dibenzo /a,i/-pyrene /DiP/, Dibenzo /a,h/-pyrene /DhP/ in the studied samples raw-fermented and smoked sausages.

From the obtained experimental results it is obvious that in higher quantities of accumulation of benzo/a/pyrene /ВаР/ are found in samples of raw-fermented sausage ‘Petrohan’ 3,63 ± 0,07) in comparison with samples from flat sausage ‘Smyadovska’ (2,04 ± 0,04), (fig. 1). It is obvious from fig. 1 that a more significant accumulation of Dibenzo /a,I/-pyrene /DIP/ (0,51 ± 0,01) is found in the studied samples ‘Petrohan’ sausage in comparison with the sample from flat sausage ‘Smyadovska’(0,20 ± 0,02), (fig. 1). The results obtained by us are in accordance with the numerous studies conducted in the late years connected with research in the content of /DIP/ since the toxicologcal studies reveal that Dibenzo /a,I/-pyrene might show a more marked carcinogenic potency than benzo/a/pyrene [2].

In our studies concerning the influence of smoking with smoke produced in the incomplete combustion of oak sawdust on the content and quantity of PAH with toxic action in raw-fermented and smoked sausages significantly higher quantities of benzo/а/-anthracene /ВаА/, Cyclopen-ta/c,d/pyrene (CPP), Benzo/в/-flouranthene /BbF/, Benzo/к/-fluoranthene/ВкF/, Benzo/j/-fluoranthene /BjF/, Benzo/а/pyrene /ВаР/, Dibenz/a,h/-anthracene/DhA/, Benzo/g,h,i/-perylene/BgP/, Dibenzo /a,I/-pyrene/DIP/, Dibenzo /а,е/-pyrene /DeP/, Dibenzo /a,i/-pyrene /DiP/, Dibenzo /a,h/-pyrene /DhP/ are found in the studied samples raw-fermented and smokes sausages (fig.1) Some compounds from the studied group such as dibenzo /a,I/-pyrene, benzo/к/-fluoranthene, benzo/g,h,i/-perylene, Dibenzo /a,h/-pyrene are considered substances posing a potential oncologic danger for the human. Enough evidence exists for their carcinogenic impact on experimental animals [1].

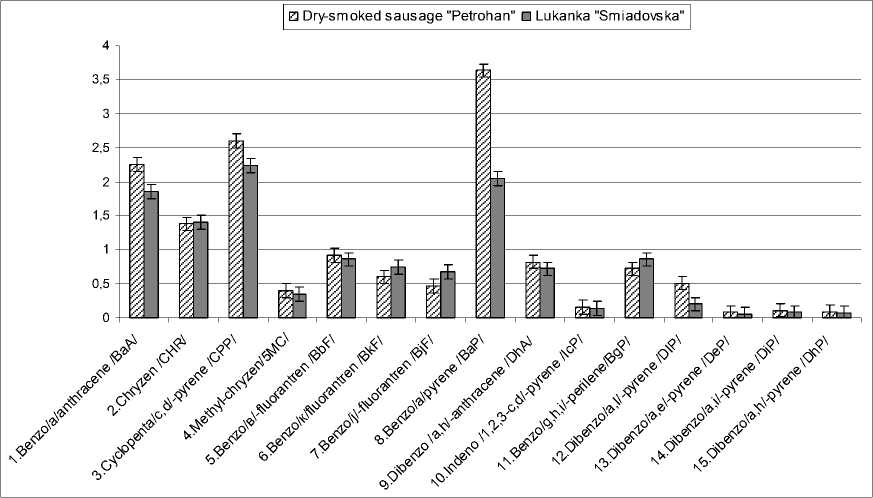

For the study of the possibilities for reducing the content of PAH in raw fermented and smoked sausages different in structure and content sausage casings are used- natural casings (pork small intestines) and artificial casings produced by the basis of the long-fiber cotton (type ‘fibrous’). The results obtained from the research concerning the influence of the different sausage casings used for stuffing on the accumulation of BaP in raw dry and raw smoked sausages are presented in fig.2. It can be seen from them that in all studied samples from both assortment (‘Petrohan’ sausage, ‘Smyadovska’ flat sausage) stuffed in natural casings and smoked with smoke produced in the incomplete combustion of oak sawdust the BaP values are significantly higher in the surface as well as in the deep layer in comparison with the regulated quantities in the samples produced in artificial casings type ‘fibrous’(fig. 2).

Q Raw dry smoked sausage "Petrohan" in natural casing

□ Lukanka "Smiadovska" in natural casing

□ Raw dry smoked sausage "Petrohan" in fibros

И Lukanka "Smiadovska" in fibros

Fig. 2 - BaP content in raw-dry and raw-smoked sausages stuffed in different sausage casings (µg/kg ).

This gives us grounds to accept that the use of suitable sausage casings such as artificial casings type ‘fibrous’ appears to be a reliable method which contributes to the significant reduction in the quantitative accumulation of various PAH and contributes significantly for the quality improvement and safety of the ready raw dry smoked products as well as for the provision of their environmental cleanliness.

Conclusions

The analysis of the results obtained gives us the grounds to make the following more significant conclusions:

-

1. The application of the technological operation smoking with the use of smoke produced in the incomplete combustion of oak sawdust does not exert significant influence on reaching the standard values of the physicochemical parameters of the studied samples from ‘Petrohan’ sausage in comparison with ‘Smyadovska’ flat sausage.

-

2. It has been found that the smoking of raw-fermented sausages with smoke produced in the incomplete combustion of oak sawdust leads to significant accumulation of higher quantities of polycyclic aromatic hydrocarbons and especially of some of the most toxic representatives (benzo/а/pyrene and dibenzo(a,I)-pyrene/DIP/), in the surface as well as in the deep layer in all studied samples from both assortments raw dry and smoked sausages.

-

3. The use of artificial casings type ‘fibrous’ in the technological operation ‘ stuffing’ in the production of raw-fermented and smoked meat products from minced meat is an effective method for considerable reduction of the content of polycyclic aromatic hydrocarbons in the final product in comparison to those stuffed in natural sausage casings.

Список литературы Influence of the smoking process on the content and quality of polycyclic hydrocarbons in Bulgarian fermented sausages

- Ким И.Н., Ким Г.Н., Кривошеева Х.Д., Хитрово И.А. Состав канцерогенных соединений типа полициклических ароматических углеводов в копченом терпучем.//Известия вузов. Пищевая технология., 2003. -№1. -С. 14 -18.

- Higginbotham S., Ramakrishna N., Johansson S., Rogan E., Cavalieri E. (1993):Tumor-initiating activity and carcinogenicity of diben-zo/a,l/pyrene versus 7,12-dimethylbenz/a/antracence and benzo/a/-pyrene at low-doses in mouse skin. Carcinogenesis 14, 875 -878.

- Falco, G., Domingo, J.L., LLobet, J.M., Teixido,A., Casas,C and Muller, L. PAHs in Foods: Human Exposure through the Diet in Catalonia, Spain. Journal of Food Protection 2003; 66(12): 2325 -31.

- Jira.W. (2005): Benzo/a/pyren in geraucherten Fleischerzeugnissen -Leitsubstanz fur das durh Polycyclische aromatische Kohlen-wasserstoffe bedingte kanzerogene Potential. Fleischwirtschaft, 85 (9). -Р. 112 -116.

- Scientific Committee on Foods of EC (SCF). Opinion of the Scientific Committee on Food in the risk to human health of PAHs in food. Brussels: SCF; 2002.

- Verordnung (EG) № 208/2005 der Kommission vom 4.Februar 2005 zur Anderung der Verordnung (EG) №466/2001 im Hinblick auf polycyklische aromatische Kohlenwasserstoffe.

- AOAC (1970) Official Methods of Analysis of the Association of Official Analytical Chemists, 11th.ed., Washington, D. C.

- Georgieva, P., Todorinov, S., Tantchev, St., Mathematical statistically methods in the techno-logical research, Agricultural Science 1989, 25, 1. -Р. 100 -109.

- Nawrot P.S., Vavasour E.J and Grant D.L. Food irradiation, heat treatment, and related pro-cessing techniques: Safety evaluation. In: Van der Heijden K., Younes M., Fishbein L., Miller S. Inter-national Food Safety Handbook; 1999. -Р. 306 -308.