Innovative approaches to quality and safety assessment of meat products based on the digitalization of the storage system

Автор: Serikkyzy M.S., Kulazhanov T.K., Baibolova L.K., Balev D.K.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 1 (147), 2025 года.

Бесплатный доступ

In the context of increasing demands for the quality and safety of food products, the integration of innovative storage technologies has become essential. This study aims to evaluate the impact of storage conditions and the Dixell XWEB300 monitoring system on the quality and safety of meat products enriched with plant-based components. The primary objective is to assess the effectiveness of digital systems in preventing oxidative processes, preserving organoleptic characteristics, and extending the shelf life of products. The scientific significance of this research lies in developing novel approaches to leveraging digital technologies for minimizing microbiological risks and enhancing the quality of meat products. The practical relevance is supported by findings that demonstrate improved microbiological indicators and preserved organoleptic properties under digital monitoring conditions compared to traditional methods. The methodology includes experiments to measure thiobarbituric and peroxide values, along with temperature and humidity monitoring under standard and digital storage conditions. The findings highlight the potential of digitalization to improve product quality and foster consumer trust. The results provide a foundation for further advancements in digital storage systems within the food industry.

Digital traceability, monitoring, storage, meat products, quality, safety

Короткий адрес: https://sciup.org/140310067

IDR: 140310067 | DOI: 10.48184/2304-568X-2025-1-35-40

Текст научной статьи Innovative approaches to quality and safety assessment of meat products based on the digitalization of the storage system

МРНТИ 65.59.31

The quality and safety of meat products are among the primary priorities of the food industry. While modern production technologies have achieved a high level of automation, methods for assessing the quality of processed meat products often remain outdated. This necessitates the adoption of new approaches, such as digitalization and the integration of artificial intelligence, to enhance the efficiency of monitoring and forecasting the quality characteristics of products.

The digitalization of production processes in the meat industry has significantly improved quality control. Scientists noted that the use of visual technologies and sensors effectively facilitates the analysis of the physicochemical properties of meat, such as texture, color, and fat content [1]. Multispectral systems successfully prevent spoilage of fresh products by monitoring changes in their structure and composition [2]. Hyperspectral technologies can be used to accurately assess the texture and moisture distribution in meat products [3]. However, these studies primarily focus on basic food products, while the impact of digital technologies on meat products enriched with plant-based components remains underexplored.

The application of digital technologies opens new opportunities for optimizing formulations, predicting shelf life, and minimizing production losses. For instance, the study «Artificial intelligence-driven automation is how we achieve the next level of efficiency in meat processing» demonstrated that the use of neural networks reduced losses by 18% [4]. Researchers from China developed an analytical platform for managing meat supply chains, which reduced logistics costs by 12% [5].

Particular interest lies in the use of computer vision technologies. These are applied to analyze the textural and geometric characteristics of raw materials, as well as to objectively assess the physicochemical properties of products [6]. Such approaches not only improve production quality but also enable the development of new products with unique consumer characteristics.

Despite the advances in digital technology applications, the use of monitoring systems such as Dixell XWEB300 for preserving the quality of meat products enriched with plant-based components remains insufficiently studied. The digitalization of storage processes could become a key factor in minimizing microbiological risks and extending product shelf life.

The relevance of this study stems from the need to address gaps in understanding the impact of digital technologies on the quality and safety of enriched meat products. The research aims to develop scientifically grounded recommendations for the application of such technologies, thereby enhancing the competitiveness of food products.

Materials and research methods

The objects of this study were meat products enriched with plant components (5% rosehip powder). The products were made from fresh, chilled beef raw materials. Samples were vacuum-packed and stored for 14 days at a temperature of 0 to +2 °C and relative humidity of 85–90%. Two groups were analyzed:

-

- Control group - products were stored under standard conditions.

-

- Experimental group - products were stored using the Dixell XWEB300 digital monitoring system.

The following methods were used in the study:

-

- Organoleptic characteristics: These included color, smell, taste, and texture, evaluated by an expert commission on the 7th and 14th days of storage. A 5-point scale was used, where 5 indicated excellent quality and 1 indicated unacceptable quality [7].

-

- Microbiological indicators: These included bacterial contamination (CFU/ml) and the presence of pathogenic microorganisms, such as Salmonella spp. and Listeria monocytogenes. Microbiological analyses were performed every 7 days using the plating method on selective media to determine the overall level of contamination and identify pathogens [8].

-

- Acid value of lipids: Determined according to the EVS EN ISO 660:2009 standard. Lipids were dissolved in 99% ethyl alcohol, heated for 2

minutes, and titrated with a hot solution of 0.1 M potassium hydroxide (KOH) using phenolphthalein as an indicator. Results were expressed in milligrams of potassium hydroxide (mg KOH) per gram of lipids [9].

-

- Peroxide value: Determined using a spectrophotometric method based on the oxidation of hydroperoxides with Fe²⁺ ions to Fe³⁺. Fe³⁺ interacted with thiocyanate (SCN⁻), forming a colored complex, the intensity of which was measured at a wavelength of 507 nm. This method was refined by Schmed and Holmer [10].

-

- Thiobarbituric acid value (TBA): Used to evaluate the degree of lipid oxidation according to the method of Botsoglou et al. Malondialdehyde, formed during lipid oxidation, reacted with thiobarbituric acid to form a colored complex. The optical density of the complex was measured at a wavelength of 532 nm using a spectrophotometer [11].

Temperature and humidity monitoring was conducted daily. In the experimental group, the Dixell XWEB300 system was used for automatic data recording, ensuring a temperature range of 0– 2 °C and humidity of 85–90%. In the control group, parameters were recorded manually [12].

The application of these methods provided accurate and comprehensive data to assess the impact of storage conditions on the quality and safety of meat products enriched with plant components.

Results and discussion

The analysis of control data revealed that the control group exhibited temperature fluctuations of up to 3.5 °C and a decrease in relative humidity to 80%. In contrast, the experimental group, utilizing the Dixell XWEB300 system, maintained a stable temperature range of 0–2 °C and relative humidity at 85–90%, ensuring optimal storage conditions (Table 1).

Table 1. Temperature and humidity indicators during the storage period

|

Parameters |

Control group |

Experimental group |

|

Average temperature |

3,5 °C |

1,8 °C |

|

Average humidity |

80% |

87% |

Comparative analysis has shown that the use of the Dixell XWEB300 system significantly improves the storage conditions of both conventional meat products and products with vegetable components. Special attention should be paid to herbal ingredients that require more stable storage conditions. The XWEB300 system allows you to preserve their properties through precise parameter control.

On the 7th day of storage, the average scores of organoleptic properties, including color, taste and consistency, were significantly higher in the experimental group compared with the control group (Table 2).

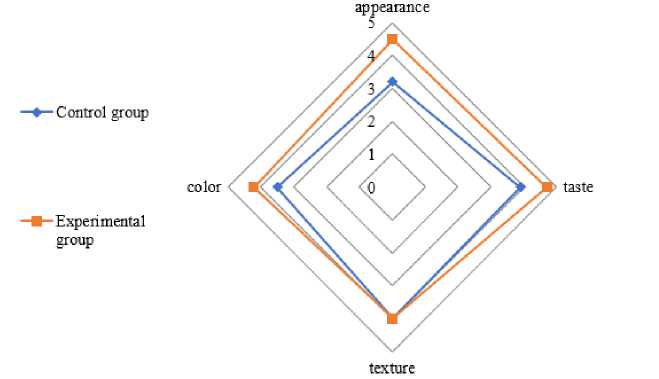

On the 14th day, the control group showed a deterioration in consistency and the appearance of a spoilage odor, while in the experimental group the organoleptic characteristics remained high (Figure 1).

Table 2. Sensory properties on the 7th day of storage

|

Parameters |

Control group |

Experimental group |

|

Color |

3.8 |

4.7 |

|

Taste |

3.9 |

4.8 |

|

Texture |

4.0 |

4.9 |

Figure 1. Organoleptic parameters on the 14th day of storage

On the 14th day of storage, the number of bacteria in the control group was 4.8×10⁵ CFU/g, while in the experimental group it was 2.5×10⁵ CFU/g. The presence of pathogenic microorganisms such as Salmonella spp. and Listeria monocytogenes was not detected in the experimental group, but traces of Salmonella were found in the control group (Table 3).

Table 3. Microbiological parameters on the 14th day of storage

|

Parameters |

Control group |

Experimental group |

|

Bacterial Contamination (CFU/g) |

4,8×10⁵ |

2,5×10⁵ |

|

Presence of Salmonella spp. |

Trace |

Not detected |

In the experimental group, the bacterial contamination level (TAMC) on the 14th day was 48% lower compared to the control group (2.5×10⁵ CFU/g vs. 4.8×10⁵ CFU/g). Pathogenic microorganisms, such as Salmonella spp., were detected only in the control group, underscoring the importance of stable storage conditions.

Hyperspectral imaging is highly effective for monitoring changes in the texture and color of foods associated with fat oxidation. The use of such technologies makes it possible to record the accumulation of hydroperoxides and the decomposition of lipids, which is clearly reflected in the values of peroxide value and thiobarbituric acid value [13]. Temperature and humidity control in the Table 4. Oxidative indicators on the 14th day of storage meat supply chain also plays an important role in reducing the intensity of oxidative processes. The use of digital technologies helps to minimize the values of peroxide value and thiobarbituric acid value, increasing lipid stability and product quality [14]. In addition, real-time digital monitoring systems demonstrate high efficiency in preventing fat oxidation, minimizing hydrolysis and secondary decomposition of lipids [15].

Oxidative indicators are key parameters for assessing the quality of fats in meat products. The study focused on three main parameters: acid value, peroxide value and thiobarbituric acid value. The results of the analysis are presented in Table 4.

|

Parameters |

Control group |

Experimental group |

|

Acid Value (mg KOH/g) |

2.5 |

1.6 |

|

Peroxide Value (meq/kg) |

6.2 |

3.8 |

|

Thiobarbituric Acid Value (mg/kg) |

0.45 |

0.25 |

In the experimental group, the acid number decreased by 36% compared to the control group. This indicates a slowdown in the hydrolytic processes in lipids due to the stabilization of storage conditions.

The peroxide value in the experimental group was 39% lower, indicating a slowdown in primary lipid oxidation.

The value of the thiobarbiturium number in the experimental group is 44% lower, which emphasizes the reduction of secondary oxidation processes.

Conclusion

The objective of this study was to evaluate the impact of the Dixell XWEB300 digital monitoring system on the quality and safety of meat products enriched with plant components. To achieve this, analyses of sensory characteristics, microbiological indicators, and oxidative parameters were conducted, highlighting the benefits of using digital monitoring systems during storage.

The results demonstrated that the Dixell XWEB300 system ensures stable storage conditions, including maintaining temperature (0–2 °C) and humidity (85–90%), significantly reducing the risk of product spoilage. In the experimental group, bacterial contamination levels were 48% lower than in the control group, and no pathogenic microorganisms, such as Salmonella spp., were detected. Additionally, sensory evaluation revealed that products in the experimental group retained high levels of color, taste, and texture even on the 14th day of storage, unlike the control group, where these parameters deteriorated.

Particular attention was given to oxidative parameters such as acid value, peroxide value, and thiobarbituric acid value. These were significantly lower in the experimental group compared to the control group, indicating a deceleration of hydrolysis and lipid oxidation processes. This underscores the effectiveness of digital monitoring in preserving the quality of fats.

The study demonstrated that the Dixell XWEB300 digital system significantly improves storage conditions for meat products, enhancing their quality, safety, and shelf life. These findings emphasize the potential of implementing such technologies in the meat processing industry to increase product competitiveness. Future research should explore the long-term effects of digital systems on the storage of various food products, as well as the development of integration with artificial intelligence for more precise forecasting and automated control of storage conditions.