Research of fire resistance of textile materials treated with different flame retardants

Автор: Burkitbay А., Jurinskaya I.M., Assankhan N.Zh.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология текстиля и одежды, дизайн

Статья в выпуске: 2 (148), 2025 года.

Бесплатный доступ

Technological solution of the proposed research is based on the use of available raw materials, excludes the use of expensive reagents, high temperatures, pressure, special equipment. The article examines the flame retardant properties of textile materials treated with imported preparations: Nortex-X (cotton fabric), Nortex-KP (nonwoven fabric) and composition of guanidine hydrochloride and sodium phosphoric acid. Research objects: cotton fabric, nonwoven material from waste linen and wool fibers, as well as flame retardants and chemical preparations (NortexX (for cellulose fibers), Nortex-KP (for nonwoven material), guanidine hydrochloride and sodium phosphoric acid). During the research work, several complex research methods were used; combustion resistance of the material was determined in accordance with the requirements of GOST R 50810-95 standard. An scanning focused-beam electron microscope JSM-6490LA (Japan) was used to study the surface morphology of textile fibers. IR spectroscopic analysis was performed using a Spectrum 65 FTIR spectrometer (Perkin&Elmer). As a result of the study it was found that textile materials treated with a composition based on guanidine hydrochloride and sodium phosphoric acid acquire high flame retardant properties. Nonwoven fabric treated with Nortex shows improved flame retardant properties. However, cotton fabric treated with this preparation does not have flame retardant properties.

Textile material, nonwoven fabric, cotton fabric, flame retardant, fire resistance, flammability, combustion, ignition, flame retardant properties, guanidine hydrochloride, sodium phosphoric acid

Короткий адрес: https://sciup.org/140310157

IDR: 140310157 | DOI: 10.48184/2304-568X-2025-2-210-217

Текст научной статьи Research of fire resistance of textile materials treated with different flame retardants

МРНТИ 64.29.23

Flammable textile products pose a serious fire hazard. They ignite easily, spread flame quickly and emit toxic smoke and gases, posing a significant threat to life. Large-scale fires due to ignition of textile products cause serious environmental damage and require evacuation. Reducing the risk of fire in domestic environments by improving the fire safety of textile products is critical to reducing the number of fire-related deaths and injuries. Significant progress has been made in the development of flame retardant textile products [1-5].

Extensive research is being conducted worldwide to improve the flame retardancy of natural and synthetic fibers. Most conventional flame retardant coatings utilize polymer matrices based on acrylic, epoxy, urethane or silicone polymers [6-8].

Recently, a number of advanced technologies such as ultraviolet curing technology, plasma technology, physical and chemical vapor deposition technology, sol-gel technology, and layer-by-layer assembly technology have attracted increasing attention in the development of flame retardant coatings [9-11].

Technological solution of the proposed research is based on the use of available raw materials, excludes the use of expensive reagents, high temperatures, pressure, special equipment.

The results of research in the form of technological developments and innovative technical solutions will be in demand at the enterprises of the RoK industry. The proposed technology will provide a high degree of realization of the tasks set in the work, will require less material and energy costs in comparison with foreign analogues, which are currently involved in most enterprises of the industry: starting with the purchase of expensive foreign equipment and inviting highly paid foreign specialists for their implementation of the implemented technologies.

In this regard, the research task is to develop compositions and technology for modification of textile and nonwoven materials using available and safe for human health preparations.

Materials methods and research

Research objects: cotton fabric, nonwoven material from waste linen and wool fibers, as well as flame retardants and chemical preparations (Nortex-X (for cellulose fibers), Nortex-KP (for nonwoven material), guanidine hydrochloride and sodium phosphoric acid).

Results and discussion

The flame retardant properties of textile materials treated with imported preparations:

Nortex-X (for cotton fabric), Nortex-KP (for nonwoven fabric) and a composition of guanidine hydrochloride and sodium phosphate were studied. Based on preliminary studies, a concentration of 20 g/l guanidine hydrochloride and 10 g/l sodium phosphate was selected. The finishing process had these conditions: aqueous solution of preparations was applied by spraying on the surface of the material, then drying at 120 °C for 5 minutes and heat treatment at 180 °C on a heat press for 1 minute. Washing at 450С, 350С, in cold water.

-

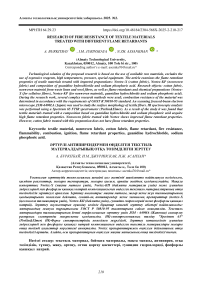

1- untreated sample; 2- sample treated after drying and washing; 3- sample treated after heat treatment and washing

-

Figure 1. Samples of cotton fabric after fire resistance test

When tested for flammability, untreated cotton fabric (sample 1) ignites in 15 seconds and burns entirely within 20 seconds. Samples treated with Nortex-X after drying and after heat treatment without washing in the test for flammability, independent combustion is reduced to zero, and after washing, the samples (samples 2, 3) slowly ignite and burn completely in 40 seconds (Figure 1).

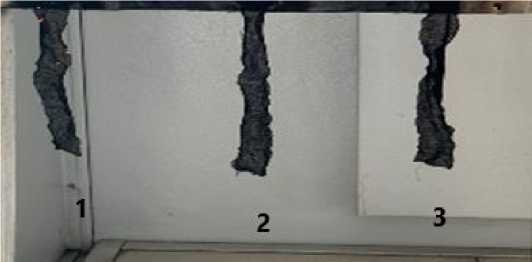

1-

sample treated after drying and washing; 2- sample treated after heat treatment and washing

Figure 2. Photograph of cotton fabric samples treated with guanidine hydrochloride and sodium phosphoric acid

A sample of cotton fabric (sample 1), treated with guanidine hydrochloride and sodium phosphoric acid and dried at 120°C for 5 minutes, ignites when exposed to a burner flame, emitting gray smoke upon ignition. But the combustion process is much slower compared to the untreated fabric sample. The fabric sample (sample 2) treated with the proposed composition did not ignite after drying and heat treatment at 180 °C for 1 minute (Figure 2).

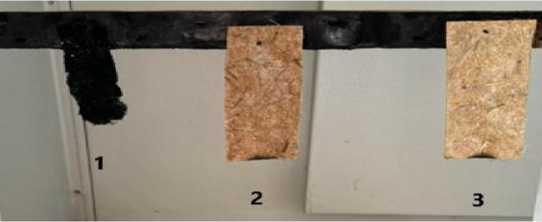

-

1- untreated sample; 2- a sample treated with a compound of guanidine hydrochloride and sodium phosphate; 3- sample treated with Nortex-KP

Figure 3. Snapshots of nonwoven fabric samples after testing for fire resistance

When exposed to flame, the nonwoven samples treated with guanidine hydrochloride and sodium phosphate (sample 2) and Nortex-KP (sample 3) did not ignite or char. In contrast, the untreated control sample (sample 1) burned, emitting gray smoke with a slight odor of burnt feathers until it burned completely (Figure 3).

As a result of the study it was found that textile materials treated with a composition based on guanidine hydrochloride and sodium phosphoric acid acquire high flame retardant properties. Nonwoven fabric treated with Nortex-KP preparation shows improved flame retardant properties. However, cotton fabric treated with this preparation does not have flame retardant properties.

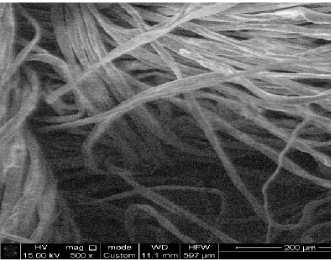

An ultra-high resolution autoemission scanning focused-beam electron microscope was used to study the morphological features of untreated and treated materials.

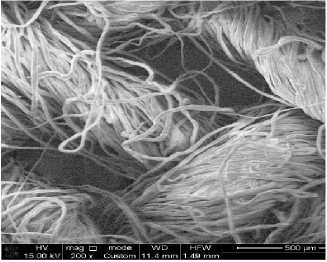

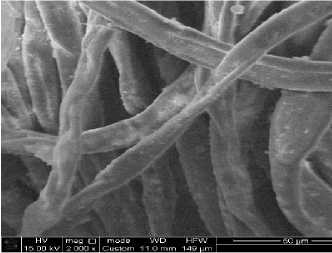

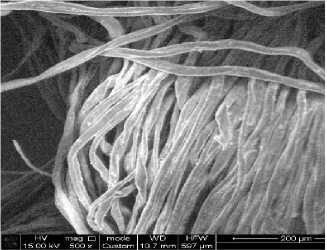

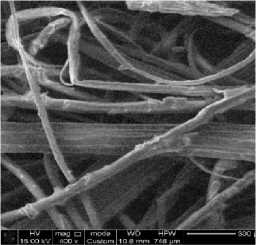

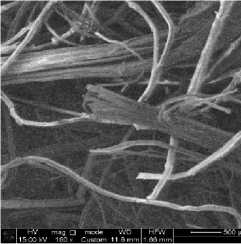

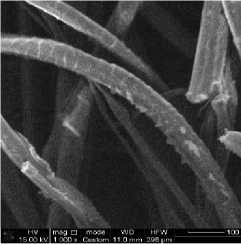

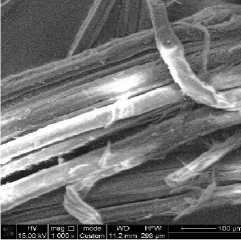

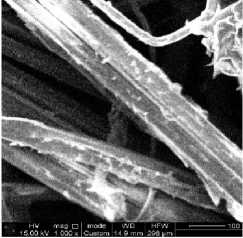

Electron-scanning microscopy results showed that the treated samples had altered surface morphology compared to the untreated samples (Figures 4, 5). Photographic analysis indicated that untreated samples had a smooth surface and homogeneous structure, while particles from sodium phosphoric acid and guanidine hydrochloride were observed on the surface of the treated materials.

a

b

c

d

-

a, b – original samples; c, d – samples treated with guanidine hydrochloride and sodium phosphoric acid

-

Figure 4. Electron microscopic images of cotton fabric fibers

a

b

c

d

e

f

a, b, c – original samples; d, e, f – samples treated with guanidine hydrochloride and sodium phosphoric acid

-

Figure 5. Electron microscopic images of nonwoven fibers

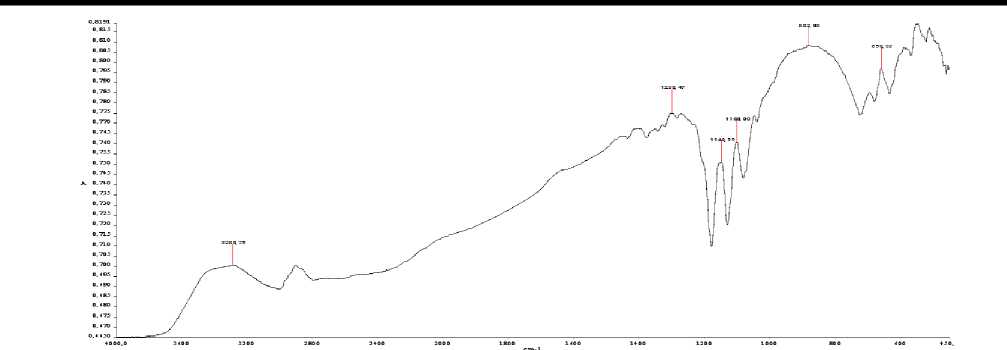

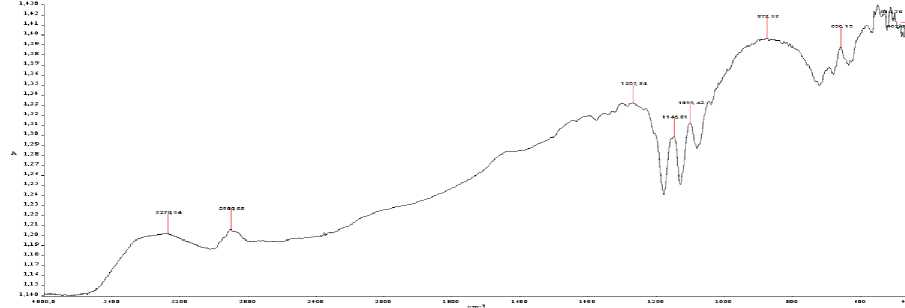

In order to fully elucidate the interaction of the application composition with cellulose fibers, IR spectra of samples of initial and treated materials were investigated in the work, which are presented in Figure 6.

When the IR spectrum of the solution-treated fiber is examined, a broad tongue-like peak of 3270.94cm-¹ is observed, which is the valence vibration signal of the hydroxyl group (-OH), and is due to the presence of moisture in the sample. The 2900.88 cm-¹ peak corresponds to the C-H valence vibration in the methylene group. The position of maxima in the interval 3300-2800 cm-¹ in both samples coincide. The implicit peak between 1700-1600 cm-¹ (typically 1640 cm-¹) in sample (a) and sample (b) corresponds to the deformation vibration of the hydroxyl group (OH).

In the “fingerprint region” of the spectra, indicator peaks of the cellulose structure of the samples are observed: asymmetric valence vibrations of C-H (1146.81 cm-¹) and symmetric valence vibrations of C-H (1099.42cm-¹) in the glucose residues of cellulose polysaccharide, as well as maxima in the frequency region of 13001250 cm-¹ indicate deformation vibrations of C-O groups in the cellulose structure.

The broad peak of 873.93 cm-¹ characterizes the strain vibration of C-O-C bridges, 656.15 cm-¹ the strain vibration of C-O-H. All other peaks below ~600 cm-¹ are usually attributed to collective vibrations of the structure (e.g., linked hydrogen bond networks in cellulose).

b

Figure 6. Graph of IR spectra of cellulose fibers untreated (a) and treated with guanidine hydrochloride and sodium phosphoric acid composition (b)

In addition, conducted tests on skin irritating effect of materials treated with the proposed method showed its safety for human health (Table 1).

Table 1. Safety indicators of cotton and nonwoven materials

|

Toxicological indicator |

Model environment |

Detected concentration (toxicity parameters) |

Permissible concentration (max.) |

Regulatory documents on research methods |

|

Local skin irritant effect |

Water extraction |

absent |

absent |

Instruction 1.1.11-12 35-2004 |

Based on the analysis of the obtained results, the treatment of cotton fabric and nonwoven material with a composition based on guanidine hydrochloride and sodium phosphoric acid provides a high degree of fire resistance of treated textile materials.

Conclusion

Treating cotton fabric and nonwoven material with a mixture of guanidine hydrochloride and sodium phosphoric acid significantly enhances their fire resistance.

Electron-scanning microscopy images reveal that untreated samples have a smooth, uniform surface, while treated samples show particles of the composition adhering to their surface.

Infrared (IR) spectroscopy analysis indicates that the treated fabrics retain all the characteristic absorption bands of cellulose. Additionally, new absorption bands appear in the spectra of the treated samples, indicating the formation of new chemical bonds between the cellulose and the treatment composition.

Acknowledgment: The work was carried out at Almaty Technological University.

Conflict of interests: The authors declare that there are no conflicts of interests between the authors to disclose in this article.