Research of safe methods of production of canned vegetables using grain crops

Автор: Sengirbekova L.K., Syzdykova L.S.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 1 (135), 2022 года.

Бесплатный доступ

This article presents microbiological study of canned vegetable snacks replaced with various cereals.Currently both abroad and in our country, regulatory documents and recommendations on ensuring quality and safety of foodsare actively developed. The quality reduction and food spoilage may be related to biochemical (fermentative) processes inherent to products themselves. As another important factor, influencing on this can be microbiological contaminants.Miroorganisms constantly contaminates on surface of technological equipments, vegetables raw material and as a result they end up in canned food. Canned vegetable snacks are ready meals, made from vegetables processedin various ways, that can be usedcold and heated. The main purpose is studying microbiological indicators of canned vegetable snacks. According to the results of the study, some types of microorganisms were found in the samples.

Canned vegetables, buckwheat, millet, cereals, haccp, critical points (kkt)

Короткий адрес: https://sciup.org/140293487

IDR: 140293487 | УДК: 664.841

Текст научной статьи Research of safe methods of production of canned vegetables using grain crops

In recent years, the problem of food quality and safety, including their ecological cleanness, has taken a special place in our country.

This is primarily caused by an increasing number of adverse anthropogenic factors and their impact on the environment,agricultural crops and productive animals.Food quality is usually understood as a set of properties that provide a person's physiological needs for food and taste substances, as well as specific organoleptic characteristics of various products.

Miroorganisms constantly contaminates on surface of technological equipments, vegetables raw material and as a result they end up in canned food.

In case of violation of temperature and humidity conditions and storage periods of canned meat, microorganisms through the activity of their own proteolytic enzymes can also noticeably change the quality characteristics of canned vegetable snacks, which may in this case become dangerous for the health of the consum-er.[7]

Currentlyboth abroad and in our country, regulatory documents and recommendations on ensuring quality and safety of foodare actively developed.At the international level, the НАССР concept received greatest recognition and dissemination, which became the main model of food quality and safety managementin many countries.HACCP is a conceptually simple system by which enterprises that produce canned food can identify and assess risks that affect the safety of their food products, and implement technological control mechanisms necessary to prevent or contain risks within acceptable limits, monitor the functioning of control mechanisms and keep current rec-ords.Currently, HACCP is the most effective system which guarantees the maximum safety of food delivered to consumers on a national scale.[1]

A critical zone in the canning industry is a defined or restricted space in which the product and the surfaces contacting with it are exposed to the environment and are at risk of contamina-tion.The HACCP procedure for identifying critical control points (CCP) serves the purpose of preventing the influence of these hazards during production.They are understood as the moment, stage or operation at which the application of control mechanisms is possible in order to prevent, eliminate or reduce to an acceptable level of risks fraught with food contamination.

The following 5 critical points should be recognized as the most rational:

-

1. Input control of raw materials upon receipt of production;

-

2. Control of temperature conditions in industrial premises;

-

3. Monitoring of technological operations in the manufacture of canned food before sterilization;

-

4. Control of sterilization modes;

-

5. Control of the modes of storage of products after sterilization.

In determining normative indicators in control critical points (CCP) of the HACCP system, it is necessary to adhere to the requirements of current normative documents (SanPiN, standards).[8]

Canned vegetable snacks are ready meals of high demand, consisting of a mixture of fried in vegetable oil and blanched vegetables and characterized by high nutrition and good taste. The study of the quality and consumer properties of canned vegetable snacks sold in retail chains is very important for research at this moment, due to the growing demand for these products.

Microorganisms in the production of canned vegetable snacks fall into a jar with the main raw material, root vegetables, root greens, tomato paste, salt, sugar, spices.A significant role in the contamination of canned food with microorganisms is played by contaminated equipment, pipelines, workwear, the use of manual processes in the processing of raw materials, poor preparation of containers, pans for raw materials, etc.Vegetable raw materials delivered to the plant, especially root crops, are heavily contaminated with various microflo-ra.Lactic acid bacteria, mold fungi, and putrid bacteria are found in large quantities. There are always bacteria of the group Escherichia coli (Coli aerogenes) and butyric acid.[3]

Mostmicrobes inside canned food do not develop and do not cause spoilage of the product, as they are oppressed by the action of high temperature during sterilization, lack of air, and in some cases, the acidic reaction of the con-tents.However, some of them (more often spore anaerobes) gradually begin to show vital activity during storage. As a result, they form gases that inflate the jar. Such spoilage is called biological puffer.Blowed canned food is not subject to use, as it can cause severe poisoning. Sometimes spoilage of canned food occurs in connection with the so-called flat-sour spoilage.This defect occurs when the residual anaerobic (spore) microflora develops, fermenting carbohydrates without the formation of gaseous products. In this regard, there is no blowing of the cans. However, the contents are spoiled when opened, it has a sour-putrid smell, a liquefied consistency.

Spoilage of canned food can be caused by yeast, mold and non-spore-forming bacteria. Yeast, mold and lactic acid bacteria can cause spoilage of canned food with a pH below 4.5. The development of yeast and lactic acid bacteria causes puffer as a result of the release of CO2.Mold is characterized by a need for oxygen and this makes it difficult for them to develop in canned food, which is in a hermetically sealed container. The presence of spores of Bysso-chlamysfulva, Aspergillus malignus and some Penicillium species in pasteurized products was found.When these microorganisms multiply, the product's marketable appearance changes, its taste and nutritional advantages decrease. Most mold fungi belong to saprophytes, but among them there are strains that have toxic properties.

Another group of microorganisms that cause spoilage of sterilized canned food is spore-forming bacteria. Usually, the vegetative cells of these bacteria are destroyed under the accepted sterilization regimes, and the spores of bacilli and Clostridium can remain alive, since they are one of the most resistant life forms of microorganisms.In terms of requirements for the temperature conditions under which they develop, spore-forming bacteria are divided into mesophilic and thermophilic. Their spores differ in temperature resistance. Spores of mesophilic spore-forming bacteria have different resistance to heat depending on the species that produces them. Some of them die at 100 °C in a few minutes, others survive at temperatures above 100°C and prolonged heating. The spoilage they cause in canned food is characterized by certain features.

When blanching, non-spore-forming microflora dies; part of the cells and spores are washed off with hot water. When roasting the main raw material at a temperature of 130-140 °C and root crops at a temperature of 120-125 °C all microorganisms die or the most heatresistant spores are preserved.[4]

Object and methods of study

Experimental research of safety indicators of canned vegetable snacks was conducted at the Institute "research Institute of food safety". Research on microbiological indicators was carried out according to the standard "GOST 30425-97".

The objects of the study were: canned vegetable snacks with various cereals of different samples. In total, 6 samples of ready canned vegetable snacks with various cereals were examined during the work.

Therewere used traditional schemes of microbiological control in the production of canned vegetable snacks, set out in GOST, guidelines, instructions in the work.

Sampling of canned vegetable snacks and preparing them for research

In accordance with GOST 30425-97, 6 cans of canned vegetables were taken for microbiological tests, which do not have any packaging defects in appearance. Each sample (product unit) was labeled according to the controlled lot code and numbered.

Canned food that delivered to the laboratory was stored at room temperature for no more than 24 hours. When studying canned vegetable snacks with signs of spoilage during the development of puffer phenomena, samples were stored in parallel at temperatures (37±1)°C and (20±1)°C. Preparation of canned vegetable snacks for microbiological study was carried out in accordance with GOST 30425-97.

Determination of mesophilic and thermophilic Clostridium spores before sterilization

The method is intended for the determination of mesophilic or thermophilic Clostridium spores. These studies were carried out with an increased number of MAFAnM in canned food before sterilization, when the microbiological defect of ready canned food was detected by the defects of puffer, "flappers", a sign of microbiological damage of 0.2%, during preventive control of the studied material was kept in a water bath for a certain time after the established temperature: to determine the spores of thermophilic aerobic, facultative anaerobic and anaerobic microorganisms at a temperature of (95±1)°C inside a test tube with the product for 20 minutes; for isolation of spores of mesophilic aerobic, facultative anaerobic and anaerobic microorganisms - at a temperature of (80±1)°C inside the test tube with the product for 20 min.

Temperature control of crops of the analyzed product, confirmation of the presence of mesophilic anaerobic micro-organisms in them, and calculation of MPN was performed in accordance with GOST 10444.4-85.

When determining thermophilic anaerobic microorganisms, temperature control of crops was performed according to GOST 10444.6-85. Determination of the number of spores of mesophilic or thermophilic aerobic and facultative anaerobic microorganisms was carried out by seeding in Petri dishes with canned food according to GOST 10444.1-85, and thermostation according to GOST 10444.185 and GOST 10444.5-85.

Determination of yeast and mold fungi

The method is based on seeding the studied product into nutrient media, determining whether the selected microorganisms belong to mold fungi and yeast by their characteristic growth on the nutrient media and by cell morphology.

This method is used for:

—determination of compliance of microbiological indicators of quality of canned vegetable snacks with the requirements of normative and technical documentation;

-

— establishment of industrial sterility of canned food;

-

— finding out the causes of defects in canned vegetable snacks;

-

— determining the degree of mold infestation in the walls of cooler rooms;

For analysis, at least (10±1) g of canned vegetable snacks were selected, homogenate and initial dilution were prepared. For this purpose, as well as for subsequent ten-fold dilutions, a saline solution was used. The Saburomedium was used in the work. Prepared dilutions from

∑N-where is the sum of all counted colonies on Petri dishes in two consecutive ten-fold dilutions, provided that each Cup has grown from 15 to 150 colonies;

n1 - number of Petri dishes, counted for less dilution;

canned vegetable snacks were sown in parallel in two Petri dishes and filled with a molten medium with a temperature no higher than (45±1)°C. In parallel, 15-20 cm3 of Saburo medium was poured into a separate Petri dish to check for sterility. The crops were thermostated at a temperature of (24±1)°C for 5 days. After 3 days of thermostatting, a preliminary accounting of characteristic colonies was performed. After 5 days, the final accounting of the results of crop temperature control was performed. Yeast and mold colonies were separated visually.The growth of yeast on the Saburo medium was accompanied by the formation of large convex, shiny, grayish-white colonies with a smooth surface and an even edge.[5,6]

The growth of mold fungi in the agaric medium was accompanied by the formation of mycelium of various colors.

If necessary, the separation of yeast and mold colonies was performed using microscopic examination. For this purpose, preparations were prepared from individual colonies using the crushed drop method. The results of microscopy are evaluated using the characteristics of yeast and mold fungi specified in GOST 10444.12-88.

The amount of yeast and mold in 1 g of product (X) was calculated byformula:

n2 - number of Petri dishes, counted for more;

and n is the degree of a smaller dilution of the product.[2]

The analysis of study results

Table 1 – Microbiological indicators of canned vegetable snacks

|

Samples |

Indicators |

||

|

Non-spore-forming microorganisms, including lactic acid and mold fungi, and yeast, in 1G (cm3) of the product |

|||

|

Yeast |

Mold fungi |

Lactic acid |

|

|

Cannedvegetablesnacks №6 (90gbuckwheat) |

1 |

- |

- |

|

Canned vegetable snacks №5 (90gmillet) |

- |

1 |

- |

|

Canned vegetable snacks №4(100gbuckwheat) |

1 |

- |

1 |

|

Canned vegetable snacks №3 (100gmillet) |

1 |

3 |

- |

|

Canned vegetable snacks №2 (110gbuckwheat) |

3 |

1 |

1 |

|

Canned vegetable snacks №1 (110gmillet) |

1 |

4 |

- |

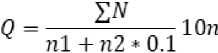

Figure 1-Microbiological indicator of canned vegetable snacks with the addition of cereals

Microbiological indicators of canned vegetable snacks with the addition of various cereals, д(см3)

СП

Е (Л

О О

и

Е ЙО с

Е

о

4,5

3,5

2,5

1,5

0,5

ф о о. V)

Mold fungi

Yeast

Lactic acid

|

№5 |

snacks |

snacks |

snacks |

snacks |

|

(90gmille |

№4(100 |

№3 |

№2 |

№1 |

|

t and |

gbuckwh |

(100gmill |

(110gbuc |

(110gmill |

|

gbukwhe |

eat) |

et) |

kwheat) |

et) |

|

at) |

||||

|

1 |

0 |

3 |

1 |

4 |

|

1 |

1 |

1 |

3 |

1 |

|

1 |

1 |

0 |

axis names

Mold fungi Yeast Lactic acid

Non-spore-forming microorganisms were found in all samples, including lactic acid microorganisms, mold fungi and yeast. This can be caused by many factors. In the future, we need to use effective methods of reducing the level of microorganisms.

Conclusions

This article determined microbiological indicators of canned vegetable snacks.According to the results of the study, non-spore-forming microorganisms were found in the samples. Microorganisms that retain their viability during heat treatment, i.e. during the sterilization of canned food, are commonly referred to as residual microflora. The cause of microbiological damage of canned vegetable snacks is the presence of heatresistant spore-forming microorganisms in the raw materials and equipment surfaces, or a direct violation of the temperature and time parameters of filling and sterilization of products. The definition of CCP in the canning industry will allow us to effectively manage critical processes, ensuring the production of high-quality and safe products. The production of high-quality canned products with a minimum con- tent of microorganisms that can preserve their original properties for a long time remains the most important task for the canning industry.

Список литературы Research of safe methods of production of canned vegetables using grain crops

- Selivanova M. V., Romanenko E. S., Barabash I. P., Esaulko N. A., Sosyura E. A., Aisanov T. S. Technology of storage and processing of fruits and vegetables. Training workshop.- Stavropol: Stavropol state agrarian University, Paragraph, 2017. - 80 p.

- Romanyuk T. I., Chusova A. E., Novikova I. V. Methods of research of raw materials and products of plant origin (theory and practice).- Voronezh state University of engineering technologies, 2014. - 160 p.

- Smotraeva I. V., Balanov P. E. Technology of products from vegetable raw materials.- Saint Petersburg: NOVOKUZNETSK, 2014. - 78 p.

- Shikina Maria Aleksandrovna "Microbiological characteristics as a critical factor in assessing the safety of production of sterilized canned meat in the HACCP system", Moscow. - 2017. -16 р.

- GOST 30425-97 Method for the determination of industrial sterility. Official publication, standardinform, 2011. - 18р.

- Basics of food preservation: textbook. manual / A. I. Mashanov, V. V. Matyushev, N. A. Velichko; Krasnoyarsky state. Agrar. Univ. - Krasnoyarsk, 2019. - 270 p.

- Sengirbekova L., Bizhanova K. Syzdykova L. S. Features of production of canned vegetable snacks. "Science. EDUCATIONS. Materials of the Republican scientific and practical conference "Youth". Almaty, April 25-26, 2019. - p. 26.

- Sengirbekova L., Bizhanova K. Syzdykova L. S. Recipes of canned vegetable snacks with various cereals. "Fundamental and applied problems of research effectiveness and ways to solve them" international scientific and practical conference. Volgograd, Russia January 28, 2020g. - 63 p.