The use of combined structuring agents of various origins in the production of jelly products

Автор: Foshchan A.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 2 (140), 2023 года.

Бесплатный доступ

This paper is devoted to solving an important task of the food industry - the rational use of food raw materials, including gelling agents of various origins. The innovative strategy of this study is based on the possibility of using gelatin and modified potato or pea starch (MS), as a cheap ingredient in the production of jelly products based on traditional, but expensive raw materials such as agar and agar from Furcellaria - furcellaran. The experimental study has been performed concerning the strength of gel-forming systems ‘gelatin - MS - agar - water’ and ‘gelatin - MS - furcellaran - water’, and systems: ‘agar - water’, ‘furcellaran - water’, ‘gelatin - water’. Mathematical models have been obtained that relate the strength of the investigated gel-forming systems to the mass concentration of their components. The equation has been obtained that allows calculating the mass concentration of the components of the studied gel-forming compositions with the given level of strength of systems. It is shown that for a given level of strength of gel-forming system there is an optimal concentration of its components in terms of the least full cost of the system. The equation that allows to calculate the optimal concentration of components of a combined gelforming system has been obtained. The adequate mathematical model for forecasting the strength of jelly products, depending on the mass concentration of components is obtained. It is envisaged to formulate the initial requirements for the parameters of gel-forming, which will allow obtaining an integral elastic structure at optimum duration of the technological process, by modelling the systems of gel-forming, as a technological system, within the framework of the functioning of individual subsystems (the creation of prescription concentrations and ratios of gel-forming agents). The obtained mathematical models can be used for the analysis of other gel-forming compositions in the presence of the data on the strength of such systems depending on the concentration of components.

Agar, furcellaran, gelatin, modified starch, jelly products, mathematical modelling

Короткий адрес: https://sciup.org/140300137

IDR: 140300137 | DOI: 10.48184/2304-568X-2023-2-147-156

Текст научной статьи The use of combined structuring agents of various origins in the production of jelly products

Introduction.

Various confectionery products, such as cakes, pastries, cookies, marshmallows, and others, are in great demand among the population, especially children. Traditionally, special substances such as agar, agaroid, furcellaran, alginates (seaweed processing products), gelatin (animal product), pectin, starch, gum (herbal products), xanthan, gelan (microbial polysaccharides), etc. are used for their production [1-6].

In today's conditions, the development of innovative competitive technologies for confectionery products is associated with resource conservation, with the creation of products of high nutritional value, improved quality with high consumer properties and extended shelf life, as well as with the increased efficiency of technological processes. The urgency of the problem lies in solving the important task of the food industry -the rational use of food raw materials, including structure formers of different origins.

To date, the world market of structure formers is estimated at approximately 4.4 billion dollars per year, and the total volume is about 260,000 tons [7]. The main principles of choosing structure formers are their harmlessness and high efficiency of action. At the same time, it is more appropriate to use natural structure-formers that are synthesized by living organisms, decompose in natural conditions and are environmentally friendly high-molecular natural compounds [8].

Agar has become the first phytocolloid to be used as a nutritional supplement over three hundred years ago. Currently, it is widely used as a gelling agent, thickener, stabilizer, and moisture-retaining agent [9-10].

Furcellaran - a substance extracted from algae Furcellaria species, also known as "Danish agar". According to European food legislation, has the code E407 [11]. The study of furcellaran and its practical significance for the food industry was carried out in scientific papers [12-14].

Gelatin is a substance of protein origin, obtained by destruction of collagen - the most common protein in nature [15-16]. The physical properties of gelatin, related to its structure, affect its quality and potential application [17-18].

Starch is one of the most widely used thickeners and gelling agents, obtained from corn, potatoes, wheat, rice, peas, etc. [19-20]. Currently, the scope of their use has expanded due to the creation of modified starches (MS). MS-starches are obtained by physical, chemical or combined processing [21]. At present, there are about 50 types of modified starches in the world, the production volumes of which are constantly increasing [22].

Currently there are no complete theories and concepts in the scientific literature that allow to foresee the technological and consumer properties of confectionery products on the basis of knowledge of the molecular structure and the nature of the structure-forming agents used for their manufacture. There are also no methods for quantitative determination of functional and physiological ingredients, adapted for confectionery products using structure-formers of different origins.

The implementation and further development of this direction will promote the rational use of food raw materials, including structureformers of different origins, in food technologies, the involvement in the technological cycle of the domestic raw materials production, the expansion of the range of finished products as well as ensuring the efficient functioning of the industry.

Previously, in the works [23-25] we offered new technologies for the production of gel products on the basis of protein-polysaccharide structure-formers using the locally produced raw materials such as gelatin, gelling potato starch, fruit and berry and fruit purees, which allowed to expand the range of confectionery products, increase their biological value, reduce calorie content and create gel and beaten-up semi-finished products with improved organoleptic, structural and mechanical properties.

The basis of these technologies is the idea of a partial replacement of expensive sulfated polysaccharides such as agar, agaroid, and furcellaran - the traditional raw materials for the production of the above products, by a composite (multicomponent) structure former consisting of agar (or agaroid or furcellaran) taken in certain proportions, as well as gelatin, and starch [23]. It has been established that the complex use of the system "protein structure-former - sulfated polysaccharide - water" leads to an increase in strength, elasticity, plasticity, melting point of the gels, with a slight decrease in the temperature of gelation of solutions, and the duration of structure forming [24]. So, at ratios of components of 0.5% of agar components - 2.0% of gelatin or 0.5% of agar - 2.0% of gelatin - 1.5% of starch it is possible to obtain structures that are not inferior to traditional ones based on 1% solution of agar [25].

The purpose of the study is to obtain mathematical models that would help to compose compositions from structure-forming agents of various nature with predetermined structural and mechanical indicators of the system at the lowest cost of compositions.

Objectives of the study:

-

1. Conducting a study of the strength of gelforming systems based on polysaccharide and protein structure-formers.

-

2. Obtaining mathematical models which link the strength of the studied gel-forming systems and the mass concentration of their components.

-

3. Obtaining equations that will allow to calculate the optimal concentration of the components of a heterogeneous gel-forming systems.

Materials and research methods

We used for this work, food gelatin P-11 (TM "Mriya", Ukraine), agar CERO Agar Agar powder Type 8925 S (CE Roeper GmbH, Germany), Furcellaran from Furcellaria fastiogata (Estonia), modified starches (MS) - oxyamyl starch potato OPV-1 (Ukraine), Farinex VA 40 - hy-droxypropylaric acid potassium phosphate (Netherlands), peanut starch Emden ESH 15 produced by Emsland Starke GmbH (Germany). Drinking water was used to prepare solutions. All systems were prepared by dissolving the appropriate weights of dry components in water.

Solutions of gelatin were prepared as follows. To the exact amount of gelatin, water was added, after which gelatin swelled for 30-40 minutes. Further, in heated bath with a temperature control, gelatin was dissolved at a temperature of 323 K, followed by cooling to room temperature. Water was added to the cooled solution with the calculation of the required concentration of the solution. The solution was then stirred thoroughly for the uniform distribution of gelatin.

The solutions of agar and furcellan were prepared in water according to the procedure similar to the preparation of aqueous solutions of gelatin, with the only difference that the dissolution was carried out at a temperature of 368 K.

The preparation of the aqueous solution of the mixture of these components was carried out by weighing dry components. At first, the agar was dissolved at 368 K in a half volume of water, then gelatin and modified starch were added to a solution cooled to a temperature of 323 K and, after its complete dissolution, was adjusted to the mass corresponding to the indicated concentrations of the components. Weighing was performed on scales with the accuracy of 0.01 g.

The determination of strength of gels and semi-finished products was carried out with Bloom strength standard method [26]. The method is based on the establishment of the ultimate load required to destroy the structure of gels with a mushroom tip. The duration of structuring was determined by a method based on establishing the maximum structural strength at the end of the structuring process. Thus, the maximum load was measured the structure was destroyed.

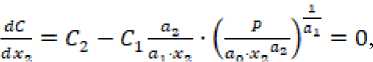

Modelling technique. Two competing mathematical models with a number of degrees of freedom n=3 were selected for modelling the experimental data on the strength of the model systems "Gelatin - MS - Agar - Water" and "Gelatin -MS - Furcellaran - Water":

Linear у = Од + ti1x1 -Ь а2х2 , (1)

non-linear у = Ощ- х.^- ■ x2Bl, (2)

where y is strength of systems, x1, x2 are mass for modelling the data on the strength of control concentrations of variable components, a0, a1, a2 - systems "Agar-Water", "Furcellaran-Water", empirical coefficients. "Gelatin-Water":

Two competing mathematical models with a number of degrees of freedom n=2 were selected linearу = Ощ + а±х, (3)

non-linearУ = Од ■ згО1 , (4)

where y is strength of a control system, x , is mass concentration of gel-former.

The form of mathematical models (1) - (4) was chosen based on the analysis of the nature of the graphic dependencies of the strength of the studied systems, the data of which are given in tables 1 - 3.

The critical value of Fisher's criterion was calculated depending on the number of stages of the model with a reliability of output of 0.95. Statistical processing of experimental data was performed in the Mathcad package environment. Co- efficients of mathematical models (1) - (4), regression variances, critical values of Fischer criteria were calculated using the built-in functions of the Mathcad package.

Results and their discussion

According to the pilot plan, 6 model heterogeneous systems (MHS) were studied based on combinations of hydrocolloids and modified starches (MS). Tables 1 and 2 give experimental data on the composition and strength of the systems under investigation.

Table 1 – Experimental parameters of the strength of model systems based on agar, gelatin and modified starches

|

The content of hydrocolloids in the model system, % |

Indicators of strength of systems with different МS, g |

||||

|

МHS 1 |

МHS 2 |

МHS 3 |

|||

|

Agar |

Gelatin |

МS |

Oxyamyl ОПВ – 1 |

Farinex VA - 40 |

Emden ESH - 15 |

|

0.25 |

1 |

1.5 |

90±5.0 |

80±4.0 |

85±4.2 |

|

0.25 |

2 |

1.5 |

180±9.0 |

175±8.7 |

185±9.2 |

|

0.25 |

3 |

1.5 |

280±14.0 |

260±13.0 |

270±13.5 |

|

0.25 |

4 |

1.5 |

350±17.5 |

320±16.0 |

340±17.0 |

|

0.5 |

1 |

1.5 |

140±7.0 |

130±6.5 |

130±6.5 |

|

0.5 |

2 |

1.5 |

240±12.0 |

230±11.5 |

245±12.2 |

|

0.5 |

3 |

1.5 |

370±18.5 |

350±17.5 |

360±18.0 |

|

0.5 |

4 |

1.5 |

410±10.5 |

390±18.5 |

400±20.0 |

Table 2 – Experimental parameters of the strength of model systems based on furcallaran, gelatin and modified starches

|

The content of hydrocolloids in the model system, % |

Indicators of strength of systems with different МS, g |

||||

|

МHS 4 |

МHS 5 |

МHS 6 |

|||

|

Furcallaran |

Gelatin |

МS |

Oxyamyl ОПВ – 1 |

Farinex VA - 40 |

Emden ESH - 15 |

|

1 |

1 |

1.5 |

110±5.5 |

100±5.0 |

105±5.2 |

|

1 |

2 |

1.5 |

200±10.0 |

180±9.0 |

190±9.5 |

|

1 |

3 |

1.5 |

270±13.5 |

250±12.5 |

260±13.0 |

|

1 |

4 |

1.5 |

350±17.5 |

320±16.0 |

340±17.0 |

|

1.5 |

1 |

1.5 |

150±7.5 |

130±6.5 |

140±7.0 |

|

1.5 |

2 |

1.5 |

270±13.5 |

250±12.5 |

260±13.0 |

|

1.5 |

3 |

1.5 |

360±13.0 |

330±16.5 |

350±17.5 |

|

1.5 |

4 |

1.5 |

430±21.5 |

400±20.0 |

420±21.0 |

Homogeneous systems (HS) from traditional gel-forming agents were investigated as control samples, the data of which is given in Table 3.

Table 3 – Experimental parameters of strength of control systems based on traditional gel-formers

|

HS1. Аgar |

HS2. Furcellaran |

HS3. Gelatin |

|||

|

The content of hydrocolloids, % |

Indicators of strength, g |

The content of hydrocolloids, % |

Indicators of strength, g |

The content of hydrocolloids, % |

Indicators of strength, g |

|

0.25 |

70±3.5 |

1.0 |

70±3.5 |

2.0 |

70±3.5 |

|

0.5 |

110±5.5 |

1.5 |

130±6.5 |

3.0 |

140±7.0 |

|

0.75 |

150±7.0 |

2.0 |

180±9.0 |

4.0 |

240±12.0 |

|

1.0 |

240±12.0 |

2.5 |

270±13.5 |

||

|

1.5 |

330±16.5 |

||||

After statistically processing the data on the strength of heterogeneous gel-forming systems shown in tables 1-2, it has been established that these experimental data are adequately described by a nonlinear mathematical model (2), and the data on the strength of the control systems given in Table 3 by a linear mathematical model (3).

Tables 4 and 5 show the parameters of mathematical models describing the dependence of the strength of the gel forming systems on their composition.

Table 4 – Parameters of mathematical models of model systems

|

Model system |

У = «0 ■ Xi-1 ■ , y – strength, g; x 1 – mass concentration of agar, %; x 2 – mass concentration of gelatin, % |

|||

|

a 0 |

a 1 |

a 2 |

Relative error, % |

|

|

МHS1 |

174.7 |

5.116 |

5.116 |

5.3 |

|

МHS2 |

1.523 |

0.452 |

0.417 |

5.4 |

|

МHS3 |

2.464 |

0.919 |

0.924 |

5.2 |

|

Model system |

у = Oq - X,-! ■ х2°= , y – strength, g; x 1 – mass concentration of furcellaran, %; x 2 – mass concentration of gelatin, % |

|||

|

МHS4 |

113.4 |

4.616 |

4.672 |

2.1 |

|

МHS5 |

1.975 |

0.673 |

0.684 |

1.9 |

|

МHS6 |

2.218 |

0.825 |

0.819 |

2 |

Table 5 – Parameters of mathematical models of control systems

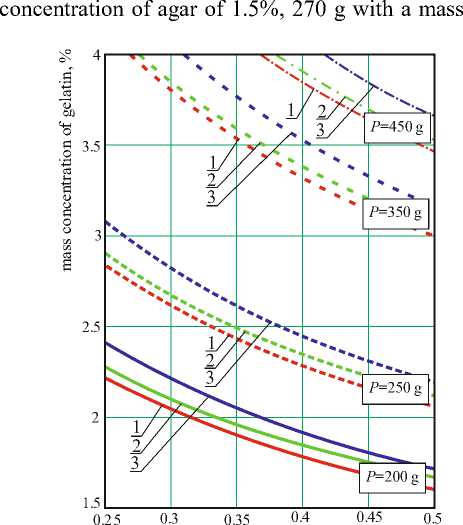

As it follows from the data obtained, heterogeneous model systems in the investigated concentration ranges have a greater gel-making capacity than control systems. The maximum strength of the control system is 330 g with a mass

mass concentration of agar, %

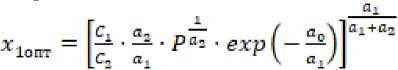

Figure 1 – Calculated strength of model systems "gelatin-MS-agar-water" depending on the mass concentration of gelatin and agar:

1 – МHS1, 2 – МHS2, 3 – МHS3.

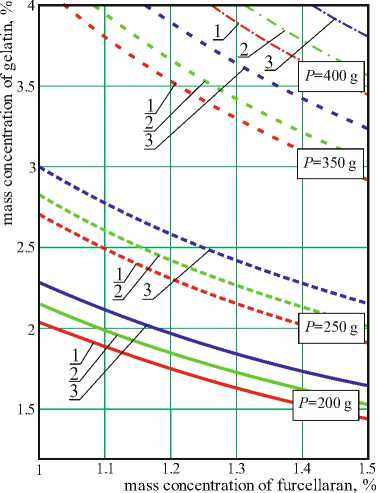

Figure 2 – Calculated strength of model systems "gela-tin-MS-furcellaran-water" depending on mass concentration of gelatin and furcellaran:

1 – МHS4, 2 – МHS5, 3 – МHS6.

Fig. 1 and 2 shows the calculated strengths of model systems depending on the mass concentrations of their components. The given range of calculated values of strength was chosen based on literary data [27] on the recommended strength of individual culinary products. So, the strength of gel for desserts in the collection of recipes on gelatin 50% of dry matter (DM) is 200 - 250 g, gel for decoration of cakes and figures 50% DM is

350 g, filling gel is 350 - 400 g, gel candies in confectionery glaze or chocolate is 350 - 400 g.

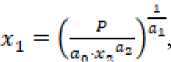

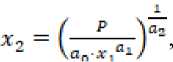

The obtained mathematical models allow us to calculate the necessary concentrations of gel forming substances at a given strength of the composition. The equation (2) gives rise to the following formulas for the determination of the necessary concentrations of the gelling agents if the strength of the system is given:

where Р is the given strength of gel a forming system, g; x 1 , x 2 are mass concentrations of hydrocolloids for a particular composition at a constant concentration of the modified starch, %.

It is clear that such combinations for one given strength of the system can be arbitrary, given the monotonous nature of formulas (5), (6). Therefore, the question arises as to how one can determine the required concentration of components of the gel making composition with a specified strength index. There are two options for solving this problem: the first one is that the concentration of components is chosen according to the organoleptic characteristics of the gel making composition, and the second on is that the component concentration is chosen based on the cost of these components.

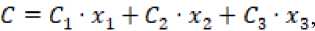

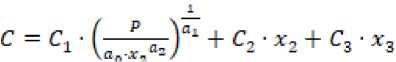

The cost of the model system can be roughly estimated by the total cost of its components (without water). In our case, given that the model system consists of three components:

where C is a full price of one model system, Cі is the price of an individual component of the system, х1 is mass concentration of agar or furcel-loran in the system, х2 is mass concentration of gelatin in the system х3 is mass concentration of modified starch in the system.

If we take into account the relations that link the strength of the system and the concentration of components (5), then we obtain:

The last equation is a function of only one variable ( x 2 ) for a given strength of system (P) and given concentration of modified starch ( x 3 =

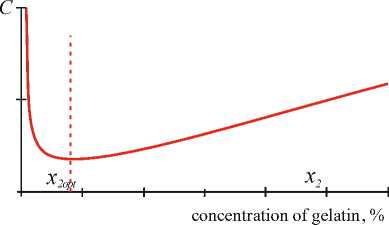

1.5%). It's easy to make sure that the price function (8) has a local minimum, graphically depicted in Fig. 3.

Figure 3 – The price of the gel making composition depending on the concentration of gelatin: x 2opt is the optimal concentration of gelatin, which corresponds to the minimum price of the composition.

This minimum price can be determined by differentiation (8) for the variable x 2

wherefrom we get the optimal concentration of gelatin in the model system, which corresponds to the minimum price of the gel making composition:

С Cl —— / д \ Q ^ + Q 2

*2orrr = f7 PQ”“eXPVf) (10)

Taking into account (5), we obtain the optimal concentration of another component in the model system:

Based on the equations (10), (11) and the data on the parameters of the mathematical model in Table 4, the dependence of the mass optimal concentration of hydrocolloids for the specified strength of the system is calculated. These graphs are shown in Fig. 4 and 5.

strength of composition, g

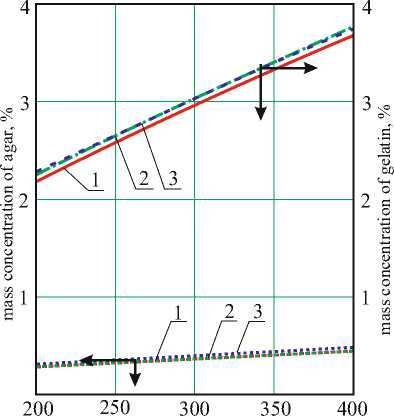

Fig. 4 – Optimal concentration of hydrocolloids of the gel-forming composition for a specified strength of the system:

1 – МHS1, 2 – МHS2, 3 – МHS3

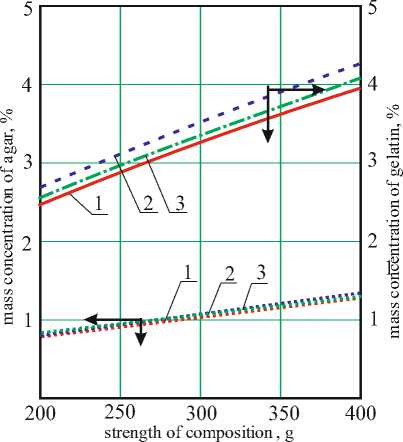

Fig.5 – Optimal concentration of hydrocolloids of the gel-forming composition for a specified strength of the system:

1 – МHS4, 2 – МHS5, 3 – МHS6

The results of the calculations given in Fig. 4 show that the optimum mass concentration of agar in the range of recommended strength for culinary products from 200 g to 400 g ranges from 0.25% to 0.43%, and the optimum concentration of gelatin from 2.1% to 3.7%, whereas model systems 1,2,3 practically do not differ in the optimal concentrations of agar.

Optimal mass concentration of furcellaran, according to the results shown in Fig.5, ranges from 0.79% to 1.31%, and the optimal gelatin concentration is from 2.47% to 4.20%, whereas model systems 4,5,6 practically do not differ in optimal concentrations of furcellaran.

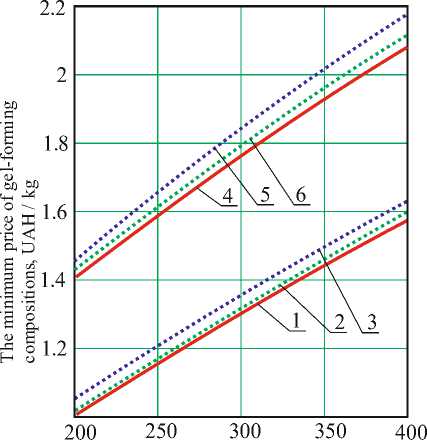

Fig. 6 shows the cost of such systems at the optimal price. In the calculation of the cost of compositions according to the formula (8), average prices for the gel-formers were taken: agar 550 UAH/kg, furcellaran 350 UAH/kg, gelatin 140 UAH/kg, starch ОPV 1 - 30 UAH/kg, starch

Farinex VA 40 - 58 UAH/kg, starch ESH 15 -58.5 UAH/kg. In the figure, the reference price is in conventional units (the minimum price is taken as a unit, and all others are indicated relative to it). It follows from Fig.6 that compositions with Farinex VA - 40 starch (MHS2, MHS5) have a higher cost compared to Oxyamil OPV 1 and Emden ESH - 15 starches with the same mass concentration in compositions of 1.5%.

In general, model gel-formers of the ‘gela-tin-MS-furcellaran-water’ system is 1.5 times more expensive than the ‘gelatin-MS-agar-water’ system, despite the fact that furcellaran is 1.5 times less expensive than agar. This is explained by the fact that systems with furcellaran (Fig. 5) with equal strength compared to agar systems (Fig.4) have a higher overall concentration of hydrocolloids, and therefore a higher cost.

strength of composition, g

Fig.6 – The minimum price of gel-forming compositions depending on the strength of the system: 1 – МHS1, 2 – МHS2, 3 – МHS3; 4 – МHS4, 5 – МHS5, 6 – МHS6.

Thus, the mathematical modelling of the gel-forming capacity of heterogeneous systems based on structure-formers of various nature allows us to solve two important scientific and practical problems:

-

1 – to make compositions from the investigated hydrocolloids, which provide the necessary organoleptic parameters and the specified level of strength of systems according to technological requirements for culinary products;

-

2 – to calculate the optimal concentration of compositions of hydrocolloids providing the specified level of strength of systems as to the indicator of the least cost of compositions.

Conclusion

-

1. The experimental study has been performed concerning the strength of gel-forming heterogeneous systems ‘gelatin-MS-agar–water’ and ‘gelatin-MS-furcellaran-water’, which use Oxyamyl OPV - 1, Farinex VA - 40 and Emden ESH - 15 modified starches and homogeneous systems: agarwater, furcellaran-water, gelatin–water.

-

2. It has been shown that heterogeneous gel-forming systems have a strength 30% greater than the control homogeneous systems based on agar, furcellaran or gelatin.

-

3. Mathematical models have been obtained that relate the strength of the investigated gelforming systems to the mass concentration of their components.

-

4. The adequacy of the models is determined by Fisher's criterion. The relative error of

-

5. The equation has been obtained that allows calculating the mass concentration of the components of the studied gel-forming compositions with the given level of strength of systems.

-

6. It is shown that for a given level of strength of a heterogeneous gel-forming system there is an optimal concentration of its components in terms of the least full cost of the system. The equation that allows to calculate the optimal concentration of components of a heterogeneous gel-forming system has been obtained.

-

7. It has been shown that Farinex VA - 40 starch compositions have a higher value compared to Oxyamyl OPV 1 and Emden ESH - 15 starches with the same mass concentration in compositions of 1.5%.

-

8. The heterogeneous compositions "gela-tin-MS-furcellaran-water" are 1.5 times more expensive than "gelatin-MS-agar-water" systems, despite the fact that furcellaran is 1.5 times cheaper than agar.

-

9. The obtained mathematical models can be used for the analysis of other heterogeneous gel-forming compositions in the presence of the data on the strength of such systems depending on the concentration of components.

approximation of experimental data by mathematical models is 2 ... 5%.

Список литературы The use of combined structuring agents of various origins in the production of jelly products

- Imeson A. Thickening and gelling agents for food. London: Blackie A&P; 1997. – 156 р.

- Saha D, Bhattacharya S. Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol. 2010; 47: 587-597.

- Milani J, Maleki G. Hydrocolloids in Food Industry. In: Valdez B editor. Food Industrial Processes - Methods and Equipment [Internet]. London: IntechOpen; 2012. Available from: https://www.intechopen.com/chapters/29151 doi: 10.5772/32358

- Dorokhovych A, Obolkina V, Kokhan O, Kyyanytsya S. Vykorystannya hidrokoloyidiv u kondyters ʹkomu vyrobnytstvi. Khlibopekarsʹka i kondytersʹka promyslovistʹ Ukrayiny. 2005; 2:9-11.

- Yevlash V, Kuznetsova T, Artamonova M, et al. Rozrobka naukovo obgruntovanykh tekhnolohiy produktsiyi pidvyshchenoyi kharchovoyi tsinnosti z vykorystannyam strukturoutvoryuvachiv riznoho pokhodzhennya. Naukovi pratsi Natsionalʹnoho universytetu kharchovykh tekhnolohiy. Kyiv; 2017; 23(5):115-123.

- Oakenfull D, Glicksman M. Gelling agents. CRC Critical Reviews in Food Science and Nutrition. 1987; 26(1):1-25.

- Phillips GO and Williams PA, editors. Handbook of hydrocolloids. CRC Press; 2009.

- Yimin Q. Bioactive Seaweeds for Food Applications: Natural Ingredients for Healthy Diets. San Diego: Elsevier Science & Technology; 2018.

- Armisen R, Galatas F, Hispanagar S. Agar. In: Phillips G and Williams P editors. Handbook of Hydrocolloids. Cambridge, U.K: Woodhead Publishing Co. 2000; 21-39.

- Stanley NF. Agar. In: Phillips G and Williams P editors. Food Polysaccharides and their Application. Boca Raton, FL: CRC Press; 2006:186-204.

- Williams PA, Phillips GO. Carrageenan and Furcellaran. In: Handbook of Hydrocolloids. Woodhead Publishing; 2009.

- Mihkel S, Kaljuvee K, Paalme T, et al. Structural Variability and Rheological Properties of Furcellaran. Food Hydrocolloids. 2021; 111:106227.

- Margus F, Eha K, Viitak A, et al. Effects of Drying on the Gel Strength and Cation Mobility of Furcellaran. Innovative Food Science & Emerging Technologies. 2000; 1(4):275-279.

- Tuvikene R, Truus K, Robal M, et al. The extraction, structure, and gelling properties of hybrid galactan from the red alga Furcellaria lumbricalis (Baltic Sea, Estonia). J Appl Phycol. 2010; 22:51-63.

- Haug IJ, Draget KI. Gelatin. Handbook of Food Proteins. Woodhead Publishing Limited. 2011:92-115.

- Reinhard S, Gareis H. Gelatine Handbook: Theory and Industrial Practice. Hoboken: John Wiley & Sons. 2007.

- Gómez-Guillén MC. Functional and bioactive properties of collagen and gelatin from alternative sources. Food Hydrocolloids. 2011; 25(8):1813-1827.

- Dasong L, Nikoo M, Boran G, et al. Collagen and Gelatin. Annual Review of Food Science and Technology. 2015; 6(1):527-557.

- Copeland L, Blazek J, Salman H, Tang M. Form and functionality of starch. Food Hydrocolloids. 2009; 23:1527-1534.

- Shevkani K, Singh N, Bajaj R, Kaur A. Wheat starch production, structure, functionality and applications. J Food Sci Technol. 2017; 52:38-58.

- Mariusz W, Ziobro R, Juszczak L, et al. Starch and Starch Derivatives in Gluten-Free Systems - A Review. Journal of Cereal Science. 2016; 67:46-57.

- Jaspreet S, Kaur L, McCarthy O. Factors Influencing the Physico-Chemical, Morphological, Thermal and Rheological Properties of some Chemically Modified Starches for Food applications-A Review. Food Hydrocolloids. 2007; 21(1):1-22.

- Foshchan A, Hryhorenko A. Vyvchennya mozhlyvosti vykorystannya zhelatynu dlya pidvyshchennya mitsnosti drahliv sulʹfatovanykh polisakharydiv chervonykh morsʹkykh vodorostey. Zbirnyk naukovykh pratsʹ. Kharkiv: KHDUKHT. 2004: 530-536

- Foshchan A, Hryhorenko A. Vyvchennya mozhlyvosti rehulyuvannya strukturno-mekhanichnykh vlastyvostey zheleynykh vyrobiv ta desertiv na osnovi sulʹfatovanykh polisakharydiv ta bilkovoho drahleutvoryuvacha. Prohresyvni tekhnika ta tekhnolohiyi kharchovykh vyrobnytstv restorannoho hospodarstva I torhivli. 2005: 164-168.

- Foshchan A, Hryhorenko A. Rehulyuvannya reolohichnykh ta strukturno-mekhanichnykh vlastyvostey zheleynykh vyrobiv ta napivfabrykativ na osnovi kombinovanykh system drahleutvoryuvachiv. Naukovi pratsi Odesʹkoyi natsionalʹnoyi akademiyi kharchovykh tekhnolohiy. 2009; 36(1):234-236.

- Phillips O, Williams P. Bloom strength— standard method for characterizing gel strength. In: Handbook of Hydrocolloids. Taylor & Francis. 2000.

- Vibhakara HS, Bawa AS. Manufacturing Jams and Jellies. In Handbook of Fruits and Fruit Processing. Ames, Iowa, USA: Blackwell Publishing. 2006: 187-204.