Safety assessment of herbal ingredients used in thick herbal pastes (appetizers)

Автор: Kulazhanov T.K., Nabiyeva Zh.S., Daribayeva G.T., Pronina Yu.G., Assembayeva E.K.

Журнал: Вестник Алматинского технологического университета @vestnik-atu

Рубрика: Технология пищевой и перерабатывающей промышленности

Статья в выпуске: 2 (148), 2025 года.

Бесплатный доступ

Functional food products based on fruit, berry, vegetable, and nut raw materials are gaining increasing popularity due to their positive impact on health. This article explores the prospects of using thick plant-based pastes (appetizers) as sources of biologically active compounds, antioxidants, and dietary fiber. The study analyzes modern production technologies, including minimal heat treatment, the use of probiotics, and innovative grinding methods. Various local and unconventional plant raw materials were used in the research, such as Torpedo melon, sugar beet, carrot, table beet, rapeseed, safflower, flaxseed, and peanuts. The study examines chemical analysis methods that assess safety (toxic elements, microbiological indicators, radionuclides, and mycotoxins) and the nutritional value of these raw materials, as well as the acid number, which indicates freshness. Special attention is given to food safety issues, including heavy metal content, microbiological indicators, and radionuclide activity. The results confirm the potential for developing enriched appetizers based on domestic raw materials, which will enhance the competitiveness of local enterprises and expand the range of functional food products on the market.

Functional foods, thick plant-based pastes, food safety, production technology, microbiological safety

Короткий адрес: https://sciup.org/140310153

IDR: 140310153 | DOI: 10.48184/2304-568X-2025-2-177-184

Текст научной статьи Safety assessment of herbal ingredients used in thick herbal pastes (appetizers)

IRSTI 65.53.35

Introduction .

Functional food products based on fruit, berry, vegetable and nut raw materials are becoming increasingly popular due to their positive impact on health. They help improve digestion, normalize metabolism, increase the body's antioxidant protection and strengthen the immune system [1].

Among such products, thick plant pastes made from fruits, nuts, oilseeds and honey are of particular interest. They have a high preventive potential and correspond to modern trends in healthy eating and sustainable development.

The phytochemical composition and health benefits of many fruits and vegetables have been studied in both laboratory and clinical studies. A statistically significant positive association has been found between their regular consumption and a reduced risk of cardiovascular disease, common cancers, and other chronic diseases. This effect is due to the high content of bioactive compounds, antioxidants, and dietary fiber [2].

Improving the technology of producing fruit and berry pastes (appetizers) requires maximum preservation of their biological and nutritional value. To achieve this, heat treatment should be minimal, the raw material's own juice should be effectively used during processing, and the products should be enriched with various additives to increase their dietary value. Important tasks include optimizing the technological process by expanding the production of semi-finished products for the canning industry and public catering, increasing equipment productivity, and rational use of labor resources, energy, and time [3].

There are many methods for producing plant pastes. For example, Japanese scientists studied the production technologies of persimmon and tangerine peel pastes, including their flavor components, color, polyphenol content, and physical properties. According to GC-MS spectral analysis, the main flavor components in persimmon and tangerine peel pastes were four and one, respectively. Folin analysis showed the polyphenol content: 33.9 mg catechin equivalent per 100 g of fresh fruit in persimmon paste and 236.3 mg in tangerine paste. Experimental data indicate that persimmon paste improves the physical properties of baked goods, in particular cookies, while tangerine paste is well suited for various processed foods. Heat treatment used for sterilization reduced cohesion but increased tensile strength and adhesion in both types of pastes [4].

An interesting study was conducted by a group of Brazilian scientists [5], who developed recipes for fruit pastes based on four types of fruits: caja, murichi, mango and pitanga. The pastes included fruit pulp, organic honey and gellan gum in different percentages. All the recipes were analyzed for antioxidant activity, vitamin C content and bioavailability in vitro. The results showed a high content of vitamin C, pronounced antioxidant properties and good bioavailability. Consumers' senses positively assessed all the recipes, with the exception of MM3 (murichi pulp: mango pulp: honey 50:50:00 and 0.25% gellan gum) and PI1 (pitanga pulp: honey 90:10 and 0.6% gellan gum).

Chinese scientists [6] have developed a probiotic fruit paste obtained by mixing fruit paste with a probiotic mixture. The probiotic mixture is formed from probiotics and carbohydrates. The probiotics include Lactobacillus acidophilus, Lactobacillus rhamnosus, Bifidobacterium lactis and Lactobacillus paracasei . Fructooligosaccharides, natural inulin, stachyose and galactooligosaccharides are used as carbohydrates.

American scientists [7] have developed a technology for producing nut paste for use in food products and beverages. The process involves processing blanched, unroasted nuts into nut flour with an average particle size of 0.002 to 0.012 inches without adding water or oil. The processing temperature does not exceed 140°F (60°C). The resulting nut flour with a moisture content of 4–6% is cooled to below 45°F (7°C) before subsequent cutting. During cutting, the temperature does not exceed 120°F (49°C), and the final particle size is from 1 to 40 microns. Almonds, cashews, macadamia, hazelnuts, pistachios, Brazil nuts, coconut, peanuts, pine nuts, walnuts, pecans, pili nuts, chestnuts, and bread nuts can be used as raw materials.

Chinese researchers [8] have developed a technology for producing a fruit and vegetable paste based on raspberries and hawthorn. The paste contains (in parts by weight): 60–70 parts raspberries, 40–50 parts hawthorn, 30–40 parts pumpkin, 20–30 parts sweet potato, 10–20 parts apples, 10–20 parts milk, 10–20 parts water, 5–10 parts corn, 5–10 parts buckwheat, 5–10 parts soybeans, 3–7 parts red dates, 5–7 parts tomatoes, 4–6 parts kiwi, 3–5 parts bananas, 3–5 parts carrots, and 1–3 parts condensed milk with sugar.

Romanian scientists [9] have developed a composition of a plant paste mixture, including the following ingredients (in mass percent): 15–45% sunflower seed paste, 1–10% acorn powder, 1– 10% beech nut paste, 40–60% water, 0.5–3% fine pink Himalayan iodized salt, 0.05–0.3% smoked paprika, 2–8% dry inactive yeast in the form of flakes, 2–8% vegetable mixture, 0.05–3% ground black pepper, 0.1–1% granulated garlic, 0.1–1.5% granulated onion, 0.1–1% thyme leaves, 0.1–1% rosemary leaves, 0.1–1% oregano leaves, 1–50 μl of edible essential oil. thyme, 1–50 µl food-grade rosemary essential oil, and 1–50 µl food-grade oregano essential oil.

Chinese researchers [10] proposed a method for producing a paste from green sea buckthorn (Hippophae rhamnoides) fruits, containing (in parts by weight): 10–30 parts sea buckthorn, 5–15 parts malt, 5–15 parts water, 1–3 parts cloves, 2–4 parts Chinese wolfberry, 3–5 parts Hericium erinaceus, 1–3 parts ginseng, 4–6 parts Chinese yam, and 5–7 parts licorice. An oligosaccharide obtained by hydrolysis is used as a sweetener, making the paste suitable for diabetics. The added cloves, Chinese yam, and licorice enhance the warming effect of the product. In addition, sea buckthorn paste has an antimicrobial effect, suppressing the growth of pathogenic fungi, staphylococci, and E. coli , which helps reduce the risk of stomach diseases.

Turkish scientists [11] studied the effect of peanut kernel size and texture on the release of aroma compounds in roasted peanuts and peanut butter both in vivo and in vitro. It was found that the intensity of aroma release in vivo was affected by the kernel size and texture. Small peanuts released more aroma compounds than large ones. Roasted peanuts had a more pronounced aroma compared to peanut butter. The key aroma compounds in roasted peanuts were methylsubstituted pyrazines and furfural. These results are important for the development of new nut products, where the degree of grinding plays a key role in preserving the aroma characteristics.

Chinese researchers [12] analyzed the flavor profiles of Linjiangxi bean paste (Vicia faba L.) using bionic sensory and multivariate statistical analysis. It was found that aldehydes were the main compounds that formed the characteristic nutty, caramel, and roasted notes of open-air fermented LBBP paste. This paste variant also had a darker color. In contrast, indoor fermented LBBP paste was characterized by a fruity flavor due to ester compounds and a brighter color. This study demonstrated that fermentation conditions significantly influenced the flavor and color characteristics of the product.

Another study [13] examined the effect of pre-adjustment of water content (5–25%) on the harmful substance content and aroma characteristics of sesame paste (SP). The results showed that decreasing the water content reduced the formation of harmful compounds. The optimal variant was SP-10, demonstrating rich notes of roasted sesame, nuts, and caramel. At the same time, SP-25, which contained the maximum amount of moisture, had the least pronounced sensory qualities, characterized by enhanced fermented and bitter flavors, indicating increased rancidity due to hydrolysis.

Rapid growth in production and expansion of the range of food products require guarantees of safety and high quality at all stages of their production and sale. However, in modern conditions, enterprises often face difficulties in ensuring unconditional safety of products in the absence of a modern system of quality control and safety of food raw materials. This problem is influenced by various factors, including pollutants, the environmental situation and climate change.

Food products are subject to rapid spoilage due to physiological processes and microbiological contamination, which can pose a danger to human health. Therefore, effective product quality management requires strict control and implementation of reliable safety measures [14, 15].

In addition to safety, the most important criterion for the quality of food products is their nutritional value. Functional food products should have high nutritional value, good taste characteristics and a favorable physiological effect on the body. A promising direction in the development of such products is the use of plant materials as a source of vitamins, minerals and biologically active compounds. To increase their effectiveness in the diet of consumers, it is important to organize production near the places of residence of the population. This allows for the maximum use of regional raw materials, expanding the range of functional products and preserving their biological value [16, 17].

This article examines the results of a study into the safety and nutritional value of enriched appetizers based on domestic plant materials.

Ensuring food safety is aimed at minimizing the risk of exposure to harmful substances, such as toxic elements and mycotoxins. Toxic elements can be part of pesticides used in agriculture to protect seeds from pests. In addition, crops growing on soils contaminated with heavy metals can accumulate them in their roots and aboveground parts.

Mycotoxins are secondary metabolites of microscopic mold fungi that are highly toxic. The main route of their entry into the human body is alimentary, that is, through the consumption of contaminated food products [18]. Mold fungi actively develop at high humidity, high air temperature, and the presence of oxygen and organic matter. Under such conditions, fungi quickly form large colonies, accumulating high concentrations of toxins, which significantly increases the risk of them getting into food products.

Currently, thick vegetable pastes presented on the market are mainly imported. The development of technology for thick vegetable pastes based on local raw materials will not only create gentle processing methods, but also increase their functional value, competitiveness in the market and accessibility to the population. This, in turn, will contribute to increasing the competitiveness of domestic enterprises, as well as successful entry into the market with innovative products [19].

The aim of this study is to assess the safety of selected garden, vegetable and oil crops required for the development of a technology for the production of enriched appetizers with functional properties.

In the course of theoretical analysis, the following types of raw materials were selected for study: oil crops (safflower, rapeseed, flax, etc.), fruits growing in the southern regions of the country, as well as vegetable components rich in pectin substances, which can be used as ingredients for the production of functional paste appetizers.

Materials and research methods

The studies were conducted at the Research Institute of Food Safety of the Almaty Technological University. The safety assessment of the raw materials was carried out in accordance with ТR CU 021/2011.

The following types of raw materials grown in the Almaty region were selected and studied as the main components for the development of appetizers:

-

– melons: melon «Тorpedo», «Lazurnaya» and «Provanskaya» pumpkins;

-

– vegetables: table beet, sugar beet, carrots and others;

-

- oilseeds: rapeseed, safflower, flax, peanuts.

Method for determination of heavy metal salts.

Determination of heavy metals (lead, cadmium, arsenic, mercury) was carried out by the atomic absorption method. The product is subjected to mineralization (dry or wet ashing), then the concentration of elements is determined by the atomic absorption method. Equipment – atomic absorption spectrometer QUANT-Z-ETA-T, regulatory documents: GOST 30178-96, GOST Р 51766-2001, GOST 26927-86.

Microbiological safety.

Mesophilic aerobic and facultative anaerobic microorganisms were determined according to GOST 10444.15-94, coliform bacteria (CGB) – GOST 31747-2012, yeast and mold fungi – GOST 10444.12-2013).

Measurement of radionuclide activity:

Methodology: analysis using radiometers and spectrometers

Operating principle: devices record the ionization of a substance under the influence of radiation, measuring the energy of an electric field, which allows determining the activity of radionuclides. Elements determined: specific and volumetric activity of cesium-137, potassium-40.

Results and discussion

The food safety of the raw materials was assessed in accordance with the requirements of ТR CU 021/2011. Table 1 shows the results of the analysis of toxic elements, microbiological indicators, radionuclides and mycotoxins for the selected garden, vegetable and oil crops.

Таble 1. Results of the assessment of food safety of raw materials

|

ад |

& о Н й о о 2 |

.S ^ Й N в |

ад 00 |

о Н |

45 |

о 00 |

д' X к! |

|||

|

Toxic elements |

||||||||||

|

Pb, mg/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

0,0029 ±0,000 1 |

0,0043±0 ,0006 |

0,0089± 0,0008 |

0,0105 ±0,001 |

|

Cd, mg/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

As, mg/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

Hg, mg/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

Microbiological indicators |

||||||||||

|

QMAFAnM, CFU/g |

3*104 |

4*104 |

5*104 |

6*104 |

5*104 |

4*104 |

Not found |

Not found |

Not found |

Not found |

|

coliform bacteria in 1.0 cm3 of product |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

Yeast, CFU/g |

7 |

1 |

8 |

9 |

Not found |

6 |

Not found |

Not found |

Not found |

Not found |

|

Mold growth rate, CFU/g |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

Radionucleotides |

||||||||||

|

Potassium-40, Bq/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

10±0,0 7 |

12±0,07 |

15±0,07 |

23±0,1 0 |

|

Cesium-137, Bq/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

|

Mycotoxins |

||||||||||

|

Aflatoxin B1, mg/kg |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

Not found |

The analysis showed that: toxic elements (arsenic, cadmium, mercury) were not detected, and the lead content was within safe limits; microbiological indicators correspond to standards: coliform bacteria (CGB) and mold fungi were not detected; mycotoxins (aflatoxin B1) were not detected; radionuclides (cesium-137, potassium-40) are within acceptable limits.

Thus, the studied samples of melons and vegetables grown in the Almaty region meet the established safety requirements and can be used for the production of food products.

The analysis of oilseed crops (rapeseed, safflower, flax (len), peanuts) was carried out according to the following indicators:

-

– Content of essential nutrients (fats, proteins, carbohydrates);

-

– Safety assessment (e.g. acid value of fat).

Таble 2. Results of physicochemical analysis of oil crops

|

Naming |

Rapeseed |

Safflower |

Len |

Peanut |

|

Mass fraction of protein, % |

29,32±0,05 |

14,75±0,08 |

19,01±0,05 |

25,39±0,05 |

|

Mass fraction of fat, % |

32,17±0,03 |

37,87±0,03 |

42,17±0,03 |

48,15±0,05 |

|

Mass fraction of carbohydrates, % |

6,54±0,03 |

26,94±0,63 |

1,54±0,03 |

7,54±0,05 |

|

Acid number of fat, мg КОН/g |

0,56±0,002 |

1,02±0,005 |

0,81±0,002 |

0,15±0,002 |

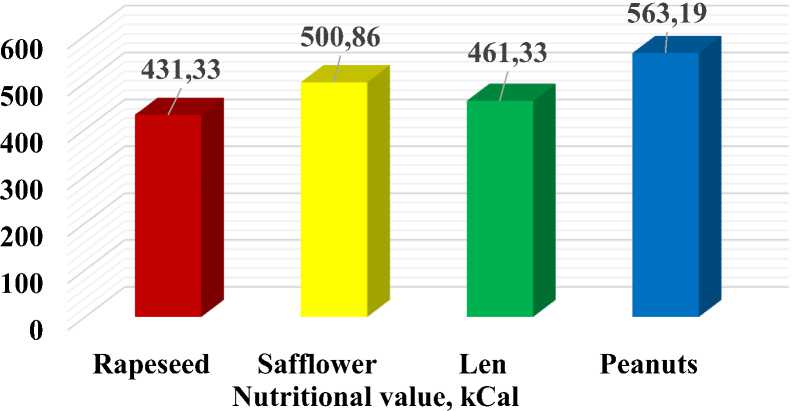

The analysis revealed that rapeseed contains the highest amount of protein (29.32%), safflower has the highest carbohydrate content (26.94%), flax and peanuts are rich in fats (42.17% and 48.15%, respectively). Figure 1 shows the nutritional value of the oilseeds under study.

Fat acidity is an important quality indicator, since: the higher the acid number, the higher the degree of oxidation and hydrolysis of the fat, which affects its freshness; oxidation of fatty acids leads to deterioration of taste and smell, and with deeper destruction – to the unsuitability of the oil for food purposes.

Рicture 1. Energy value of oilseeds

Oilseeds (rapeseed, safflower, flax, peanuts) have high nutritional value due to their significant protein and fat content. The main energy components of food are proteins, fats and carbohydrates, and their balance determines the nutritional value of the product. The data obtained allow us to calculate the caloric content and value of ingredients for developing appetizers.

Conclusion .

Modern functional foods, including thick vegetable pastes, are a promising direction in the food industry due to their high nutritional value and positive impact on human health. Analysis of production technologies shows that minimal heat treatment and the use of natural components help preserve the biologically active substances of raw materials.

The Kazakhstan market is dominated by imported fruit, nut and honey pastes, while domestic analogues are virtually absent. The development of the production of functional thick pastes based on local raw materials will not only satisfy the population's needs for healthy nutrition, but also increase the competitiveness of domestic producers.

In the future, it would be advisable to conduct additional research aimed at improving recipes and technological processes, as well as assessing the impact of such products on consumer health.

Funding .

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR24993031, "Development of technology for preparing healthy food products for the daily diet, enriched with natural antioxidants and biologically active substances").